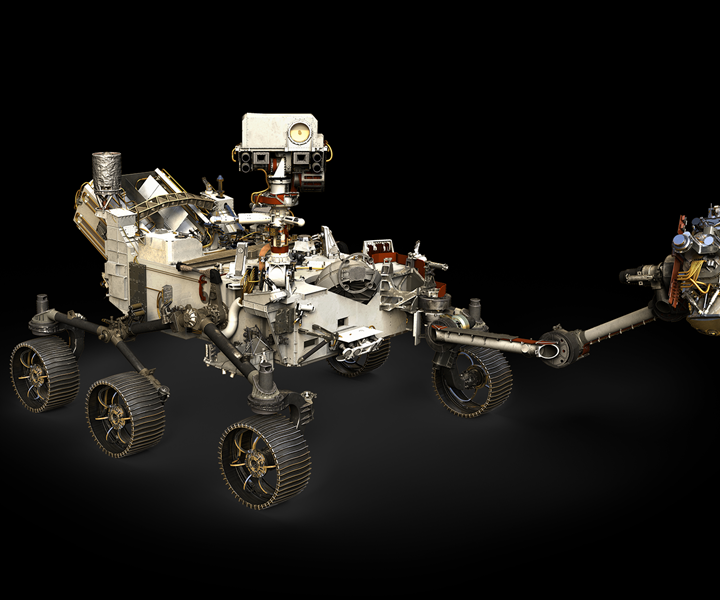

Composites training firm lends a hand with Mars rover

Advanced Composites Training helps train NASA engineers in the use of composite materials for construction of the Mars 2020 rover.

Source | NASA

Of all the exciting applications that CW gets to report on, space applications are some of the ones that are especially quick to capture my imagination. Whenever a space story crosses my desk I jump at the chance to cover it, so I can only imagine how excited Wilson Boynton, founder and president of Advanced Composites Training (ACT, London, Ontario, Canada) was to be invited to NASA’s Jet Propulsion Laboratory (JPL, Pasadena, Calif., U.S.) to help train engineers in the use of composite materials for construction of the Mars 2020 rover.

According to Boynton, ACT has been teaching people to work with composites since 1996. ACT is reportedly the only privately-owned Canadian composites training institute meeting both Transport Canada and American Federal Aviation Administration standards. The company works with both civilian and military technicians from more than 39 countries worldwide.

“The level of hands-on training we offer makes our company unique,” says Boynton.

ACT’s approach attracted NASA’s attention for help with composites used in the construction of its Mars rover. “They realized they didn’t have a full grasp of the material and process technologies and wanted to eliminate any issues,” says Boynton. “When it comes to actually building the rover there are so many things that can go wrong.”

Boynton provided a team of JPL engineers with intensive training in composite manufacturing and repairs.

According to NASA, the Mars 2020 rover will be around 10 feet long, 9 feet wide and 7 feet tall (3 meters long, 2.7 meters wide, 2.2 meters tall) – but at 2,314 pounds (1,050 kilograms), the rover will weigh less than the average compact car. It needs to be both lightweight and durable for the journey to the Red Planet and also needs to be strong enough to carry cameras and scientific instruments, as well as the Mars Helicopter — another composites intensive craft that will be used to explore the planet.

As for Boyton, he describes his five days at the Jet Propulsion Laboratory a “bucket-list moment” and is looking forward to future opportunities to work with NASA.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.