Continuous Fiber Manufacturing (CFM) with moi composites

Continuous fiber 3D printing using epoxy, vinylester and acrylic with continuous glass, carbon, basalt and other fibers, including deposition along nonlinear curves, is only the beginning.

Continuous fiber 3D printing and deposition is gaining momentum. As the number of companies using and advancing it grow, this technology will undoubtedly shape the composites industry.

First, it offers fabrication without molds or tooling. Second, it offers multifunctional structures (e.g., electrical conductivity, shape-changing, sensing). Third, it opens the door to a world of hybridized manufacturing — e.g., lamination on top of 3D printing and milling while printing — as well as an almost endless landscape of materials development, from Nitinol shape memory alloy (SMA) fibers to conductive nanocomposite solutions for liquid deposition modeling (LDM). The latter is a whole world in itself which I will come back to in a future blog.

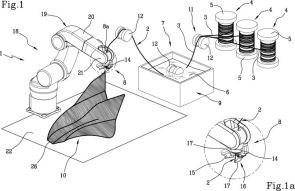

Patent WO2017085649A1 and Atropos printing system. SOURCE: moi composites.

Moi composites was established in Feb 2018 by materials engineer and professor Marinella Levi, design engineer Gabriele Natale and architect Michele Tonizzo. In 2013, professor Levi started working with 3D printing at the Politecnico di Milano (Milan, Italy). By 2014, she had formed +LAB in the university’s Chemistry, Materials and Chemical Engineering "Giulio Natta" Department. Her vision was to meld R&D, teaching and materials innovation by drawing together engineers, designers, researchers and makers into a multidisciplinary, collaborative 3D printing hub.

| 2014 | First tool for 3D printing continuous fiber thermoset composites |

| 2015 | Patent WO2017085649A1 |

| 2016 | Partnerships with Owens Corning and KUKA Robotics, Atropos project and printing system |

| 2017 | JEC Innovation Award, partnership with Autodesk, James Dyson award runner-up, Partnership with COMAU automation (Full timeline) |

“We started moi composites because we wanted to produce commercial parts and be involved in international projects,” explains Michele Tonizzo. “We’ve discovered there is plenty of market. We are making biomedical components as well as parts for marine, oil & gas and aerospace applications, mainly using glass fiber. The CFM technology is able to the manufacture unique solutions that would be impossible with traditional methods."

|

3D printed propeller blade with internal structural truss using continuous glass fiber (top). This project also demonstrated fiber placement along nonlinear curves (bottom left) and continuous fiber laminate with traditional fiber orientations (e.g., 0°,+45°, -45°, 90°, bottom right). SOURCE: moi composites

Range of resins and fibers

Atropos demonstrated the ability to print discontinuous and continuous fiber-reinforced, thermosetting polymers not just layer by layer, but also along nonlinear curves. It used ultraviolet (UV) light for curing the polymers in place. “We currently can print with UV-cure in epoxy, acrylic and vinylester,” says Tonizzo. He notes that acrylic works wells for architectural parts because it is clear and does not require temperature for cure/post-cure. Vinylester is used for marine parts and epoxy for oil & gas and aerospace parts.

“For some applications, UV cure is just the initial stage and then we post-cure with conventional heating,” Tonizzo observes. “We are not tied to UV curing. We have printed with non-UV curing polymers and understand that for higher property applications we will need different matrix options.” For reference, the glass transition temperature (Tg) for their most commonly used resin, a vinylester, is around 140°C.

“We are also working with carbon fiber but not with UV cure resins,” says Tonizzo. He points out that both fiber transparency and color affect UV cure. “The issue with carbon is that it is opaque and black. This is the worst combination. We want to develop the best solution for carbon fiber as a material, not just the easiest technology that works. There are a lot of other curing material options we can use, so we are investigating these.”

Moi composites can print continuous conductive fibers for electrical/thermal functionality, sensing, shape-changing, etc. SOURCE: moi composites.

Moi composites has printed continuous glass fiber up to 2400 tex (207 yd/lb with a maximum diameter of 24 μm per an Owens Corning datasheet) and is testing natural fibers. It has also printed with basalt fiber. “We can print very well with UV cure and basalt fiber because it is actually somewhat transparent and more brown than black,” Tonizzo explains.

Fibers that conduct electrical current may also be used in the CFM technology. They can be placed as needed in the structure being printed. One of the projects listed on the +LAB website shows Nitinol fiber, which is a memory shape alloy. “So you could make shape-changing structures,” says Tonizzo. “For example, you could use it to release stress on other fibers, like in prestressed concrete.”

3D printing as part of hybrid manufacturing

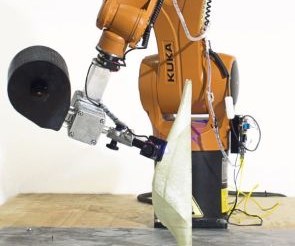

Atropos uses a Kuka robotic arm with a print envelope of 0.5 x 0.5 x 0.5m height. “We are now printing on a Comau robot with a 1.0 x 0.5 x 0.8m height envelope, which is the second-generation system,” says Tonizzo. “We have also used larger robots with rotary tables and build volumes of 1.5 x 1.5 x 1m height and demonstrated that our technology is easily scalable.”

Moi is also developing a third-generation, all-in-one print head with a system to apply pressure to the fibers, sensors, cutting mechanisms and milling tool.Tonizzo says this will close the gap between 3D printing and automated fiber placement (AFP). “3D printing does not achieve the performance of AFP, but CFM offers more flexibility. We can already print with fibers .25mm in thickness and have the ability to create curves and place continuous fibers in the ideal position,” he adds.

|

|

SuPeRIOR is a lower limb prosthetic optimized for minimum weight, deflection and cost.

The 3D printed structural core was then laminated with carbon fiber and epoxy resin followed by VBO cure. SOURCE: moi composites.

“3D printing should be used for what it does best,” says Tonizzo, “which includes optimizing work flow. For example, you can 3D print an internal core with undercuts and smart fiber directions. You then use common hand lamination on top and cure in an autoclave or with vacuum bag only.” He describes a part that was impossible to make conventionally with a mold. “We printed the internal core and then wrapped it in laminate and autoclave cured it at 110°C and 2 bar of pressure for several hours. The part came out great.” This part is covered by a non-disclosure agreement, so no further details are available, but moi has produced the SuPeRIOR prosthetic in a similar manner, cured not in an autoclave but with vacuum bag only (VBO). “All of the internals are using one continuous glass fiber,” he explains, “but the outer laminate is hand layup carbon fiber fabric and epoxy resin.” The whole design reduces deflection and increases customization while significantly cutting cost and production time.

Voxel-based optimization software

Tonizzo explains that the part design process combines Autodesk's voxel-based algorithm with moi's algorithms for stress and path optimization. This is what produces the optimized fiber path for the structure. The software also works to choose the path most possible to manufacture. “This is an iterative process,” says Tonizzo. “The design is not fully automated like generative design. It still needs engineers to make choices. But I think this is how it should be — the designer and the software combined, not just AI alone.”

Multi-material future, strong market potential

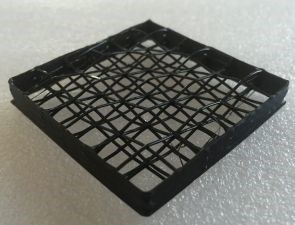

In one of the images from the Atropos printed propeller blade, there is a close up showing an almost woven pattern. “This is not actually woven but it will be possible soon,” says Tonizzo. He directs me to the sine wave project on the +LAB website. “The demonstrators shown are 3D printed in plastic with short fibers and the LDM [liquid deposition modeling] process while were researchers at +LAB. The algorithms we used then are the same we are now advancing with continuous fiber.”

Moi composites sees “woven” type printed structures as possible near term (top).

SOURCE: moi composites.

+LAB’s Sine Wave demonstrates 3D printed polymer infill patterns with a tunable elastic response. SOURCE: +LAB.

It is obvious from the +LAB website, that material innovations and possibilities for this type of printing is almost endless. The question is what will offer the most opportunity and potential for high-demand solutions. Meanwhile, material suppliers are supporting continued development. For example, Owens Corning is interested to demonstrate glass fiber with more matrices, like ceramics and concrete. Obviously, this is very interesting for building and construction applications, and could have significant potential in light of the current trends for digital fabrication and energy-efficient construction, offsite prefabricated modules and improved sustainability via natural and recycled materials, all of which stress lightweight. “The Giulio Natta Department at the Politecnico di Milano is in an EU project for printing geopolymers which behave like concrete,” adds Tonizzo. “They are cured by themselves with time but have the consistency like clay during printing for better flow. We will definitely keep working in this area, as well as with new polymers and fibers.”

|

|

Moi composites is also printing with geopolymers, which behave like concrete.

SOURCE: +LAB.

Will you sell machines? “Yes, but in the future,” says Tonizzo. “For now, we are producing parts and bringing the technology to the client's facility, using our know-how, print head and software to realize part solutions on demand.” He adds that having worked this past year to improve the technology with CFM early adopters, and demonstrate the business case for many different parts in different markets, moi composites is now seeking investors to further scale CFM machines and processes for commercial market opportunities.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read More3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More