Visit the news pages of the Airborne Oil & Gas (AOG, IJmuiden, Netherlands) and Magma Global Ltd. (Portsmouth, U.K.) websites and you’ll come away with the impression that 2018 was a watershed year for these two leading manufacturers of thermoplastic composite pipe (TCP) for deep-sea applications. But don’t be surprised if 2019 news about this burgeoning market for composites eclipses that of the preceding year.

A few notable achievements of 2018 for AOG: In June, the company commenced a qualification program for carbon fiber/polyvinylidene difluoride (PVDF) risers (pipes connecting subsea production systems and surface production vessels) for a major operator in South America. AOG worked in collaboration with Subsea 7 (Luxembourg), a major offshore installation contractor, on this project. In August, after an extensive five-year qualification program followed by the world’s first pilot installation on hydrocarbon (full well bore) service of a glass fiber/high-density polyethylene (HDPE) flowline (pipe that connects the well head to further processing equipment), Petronas (Kuala Lumpur, Malaysia) recognized AOG’s TCP flowline as having achieved technology readiness level 6 (beta prototype verification). “And we expect to reach TRL 7 [pilot system demonstration] in 2019,” reports Martin Van Onna, AOG CCO. Along with these successful qualifications and pilot programs, AOG reports a growing commercial track record, especially with its glass fiber/HDPE TCP.

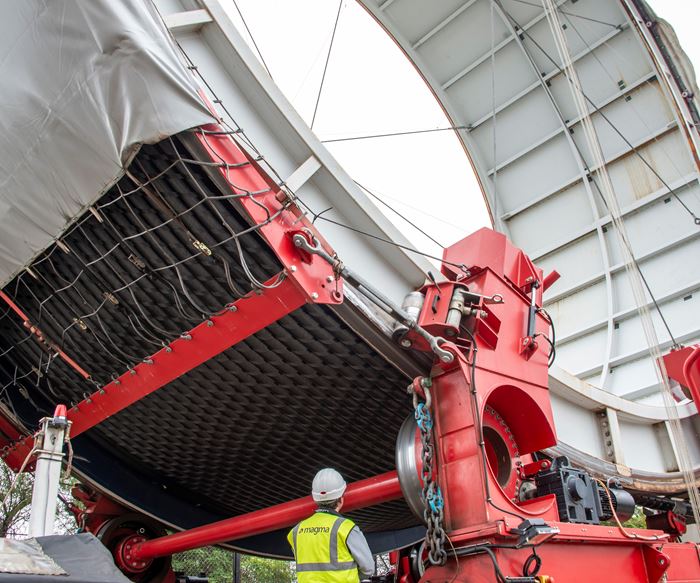

As for Magma, 2018 was equally eventful. In March, Tullow Ghana awarded a contract to Magma for a 2.5-kilometer flowline for its development of Tweneboa, Enyenra, Ntomme (TEN) offshore fields. In May, working with Ocyan (Rio de Janeiro, Brazil), an offshore services company, Magma completed and received third-party validation of a Composite Multi-Bore Hybrid Riser (CMHR) design that employs Magma’s carbon fiber/polyetheretherketone (PEEK) m-pipe. Magma and Ocyan are bidding the CMHR for deep-water developments in Brazil. Magma announced in August that a joint initiative with Equinor (Stavanger, Norway) had secured £10.5 million in funding from Innovate UK, a government funding source, to qualify an all-Magma solution for jumpers (pipes that connect flowlines and/or subsea facilities). Finally, in November, the Energy Institute (London, U.K.) bestowed its 2018 Award for Innovation to Magma for its m-pipe, citing the pipe’s ability to solve the challenges of oil and gas production in deepwater reserves, as well as its ability to be reused.

In 2019, AOG and Magma have big plans for increased production capacity as they serve the blossoming composites market. “Especially in the second half of last year,” Van Onna affirms, “the demand is growing so fast that we really need to grow very, very quickly.”

TCP appeal

Underscoring this rapid growth is the relatively brief history of TCP deployment in deep-sea oil and gas applications. Note that TCP is distinct from reinforced thermoplastic pipe — RTP — which has been around since the 1990s. RTP consists of a thermoplastic liner overwrapped with unbonded aramid or glass fiber composites, then coated with thermoplastic. It is used in lower pressure and less demanding temperature applications compared to the fully bonded TCP. Although TCP consists of a similar set of materials, it is suited to higher pressures and a greater temperature range for two reasons. First, some TCP uses higher performing thermoplastic resins, such as PEEK, and/or higher strength reinforcement like carbon fiber. Second, TCP layers are bonded to each other through a melt-fuse manufacturing process, which yields higher performance properties than RTP made from the same materials.

Only 11 years ago, Van Onna recounts, no TCP had been deployed in deep-sea applications. Then in 2009, AOG developed and deployed the first offshore TCP downline (used to pump fluids down to the seabed for injection into subsea pipelines or subsea wellheads). The company built a full-scale TCP production site in 2012. By 2018, AOG had increased production capacity to include three production lines as well as manufacturing capability that includes glass fiber/HDPE for applications up to 65˚C/150˚F and 5 ksi; carbon fiber/polyamide 12 for applications up to 80˚C/180˚F and 10 ksi; and carbon fiber/PVDF for applications up to 121˚C/250˚F and 15 ksi.

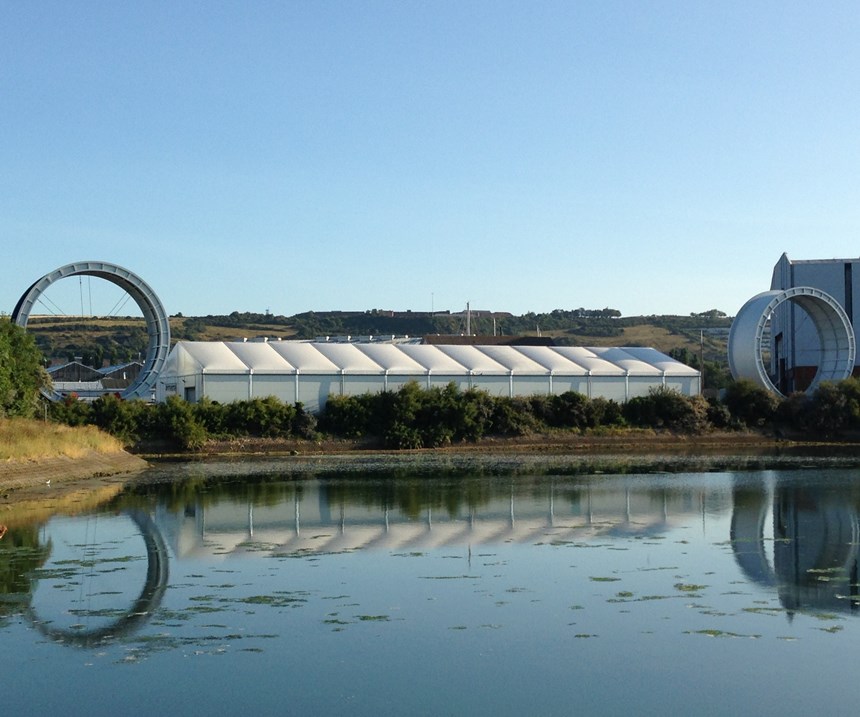

In the meantime, Magma was founded in 2009 and began deploying its m-pipe in 2012, opening its production site in Portsmouth, U.K. in 2016. At the company’s five-year anniversary celebration, CEO Martin Jones commented, “The aviation industry is a good precedent where the use of carbon fiber is now standard. It is now also happening in oil and gas. We are currently engaged with all of the major operators.”

The growing adoption of TCP stems from its numerous cost-saving advantages over conventional pipe. For example, despite higher cost of materials, AOG’s highest performance carbon fiber/PVDF in a flowline application generates a reported 30 percent savings on as-installed cost compared to metal flowlines. Similarly, a Calash (London, U.K.) commercial review of m-pipe versus steel in a single-line offset riser (SLOR) application estimated an as-installed cost savings of 11 percent. These savings result from several TCP properties that make transportation, preparation (for example, terminating pipes with end fittings), and installation considerably less expensive than performing these tasks with pipes made from other materials.

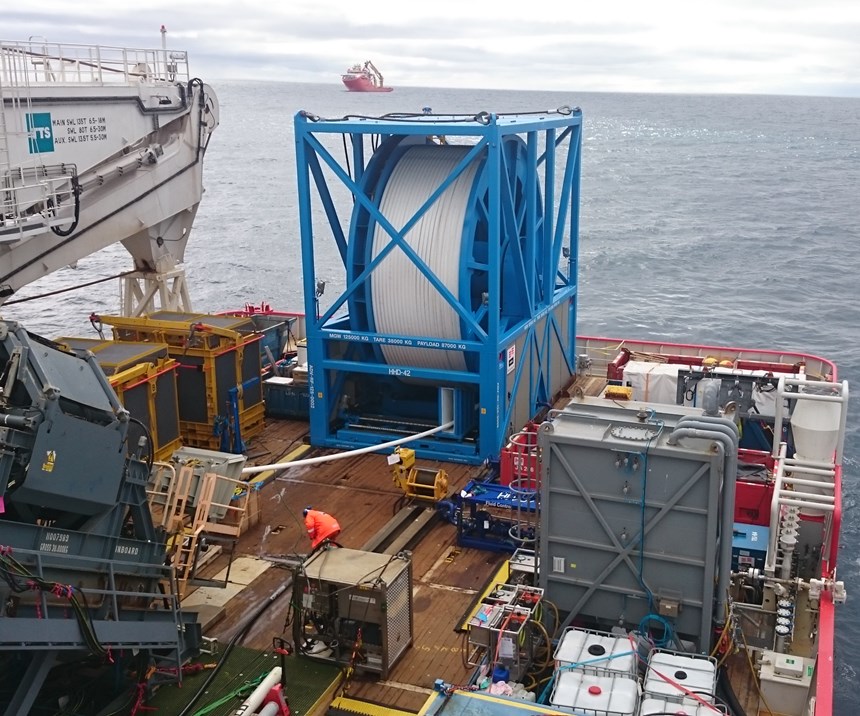

As is often the case with composites, the first such property is light weight — TCP weighs as little as one-tenth the weight of steel pipe — but the combination of light weight and flexibility of the pipe makes for a critical advantage: the pipe can be spooled on relatively small drums and subsea pallets. Because of this, smaller vessels can transport and install long spans of TCP — a logistical and economic boon in more remote offshore locations (for example, off the West African coast), where deployment of conventional heavy-lift vessels is a costly proposition. Another cost-saving advantage created by the melt-fusing capacity of TCP is that the pipe can be terminated and end fittings installed onsite.

TCP offers a combination of high strength, flexibility and ease of termination, giving it the best qualities of conventional metal pipe (strong but rigid) and flexible pipe made from unbonded layers of helically applied metal wires and extruded thermoplastics (flexible but heavy, and very costly to terminate onsite). TCP is fully capable of efficiently handling the demanding pressures and temperatures of subsea applications — both from external conditions and from the internal conditions created by the fluids moving through them. TCP’s thermoplastic liner also offers high flowrates due to its low coefficient of friction. Finally, two other key TCP properties — corrosion and fatigue resistance — make TCPs highly durable, even as energy companies are more frequently pumping sour (that is, acidic) crude oil found deeper underground.

Accelerating pipe production

Preparing to meet accelerating demand, AOG is one year into a three-year program designed to increase the company’s production capacity by a factor of five. “We are implementing more than 10 individual measures that all lead to increased production capacity,” Van Onna says.

TCP is produced at AOG in three continuous steps. First, a thermoplastic liner is extruded. Next, automatic tape laying (ATL) with in-situ consolidation winds anywhere from a few to 100 layers of the fiber-reinforced thermoplastic tape, with each layer melt-fused onto preceding layers. Lastly, the pipe is run through a coating extrusion die. This is not regular coextrusion, Van Onna explains. “We melt the outside composite layer and pressure-form the coating onto the laminate. The result is a pipe with high shear strength between the coating and laminate, which enables our clients to terminate our TCP anywhere, while maintaining a high-strength, durable and protective coating.”

AOG is adding winding stations, an obvious way to increase capacity, but it is also increasing extrusion and winding speeds. The company has integrated a proprietary automatic inspection system on the production line, which ensures consistent characteristics and properties even as production speed is increased.

Magma’s production process bears a resemblance to AOG’s. Magma m-pipe consists of about 25 percent carbon fiber, 25 percent S2 glass fiber and 50 percent PEEK. Magma refers to its manufacturing process as a “fully automated robotic 3D laser print process.” It consists of extrusion of a smooth-bore inner pipe precursor made from PEEK onto which an ATL process uses a laser to fuse alternating layers of glass fiber/PEEK and carbon fiber/PEEK tapes. Magma selected PEEK, which the company acquires from Victrex (Lancashire, U.K.), because of its very high fatigue capacity. Toray Industries (Tokyo, Japan) supplies the reinforcements used in m-pipe. Magma is keeping up with production demands not only with its internal Portsmouth, U.K., production line but with mobile in-country manufacturing modules (ICMM), the first of which is also operating in Portsmouth. Magma anticipates deploying more ICMMs, since the company favors local production, both logistically and financially, especially for riser applications.

Commercial success soon

Importantly, the development of TCP has been accompanied by the creation of a formal standard for design and qualification of TCP in subsea applications. The road to this standard has been painstaking, Van Onna says, but the result is a document and guideline that engenders among energy professionals a great confidence in the product’s long-term performance, as well as its expected cost in use. Such confidence, one can imagine, is critical in a highly regulated and closely watched industry like offshore oil and gas production, where pipe failure is simply unacceptable. The standard, Van Onna explains, covers the qualification of the base materials as well as the design method and, of course, the production technology. AOG has been able to demonstrate that its TCP base materials and production quality are equal to those of the benchmark, autoclave-cured composite structures like those used in aerospace.

AOG’s approach to qualification, Van Onna continues, was to “run separate qualification for all our base materials. Then we design and manufacture pipe of any size using those qualified materials.” Achieving qualification and climbing through TRL levels, TCP is now poised for a mass volume of products beginning in 2019, Van Onna believes.

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More