CSP Van Wert Facility turns 40

Continental Structural Plastics compounding facility in Van Wert is celebrating 40 years in business.

Continental Structural Plastics (CSP, Auburn Hills, MI, US), molder of light weight composite technologies for the automotive industry, announced June 18 that its compounding facility in Van Wert, OH, is celebrating 40 years in business.

Because CSP develops and compounds its own composite formulations, Van Wert’s ability to compound impacts many of the company’s global automotive customers. Of the more than 84 thousand tons of sheet molded compound (SMC) compounded by CSP annually, more than 60 thousand of those come from the facility in Van Wert. Much of that is the company’s own, proprietary formulas created by CSP’s team of chemists and engineers located at the company’s global headquarters and R&D center in Auburn Hills.

The Van Wert facility was originally built by The Budd Company to support the organization’s growing customer demand. Its molding plants had a number of new programs including the Corvette fastback, roof and rear fenders, so more SMC was needed.

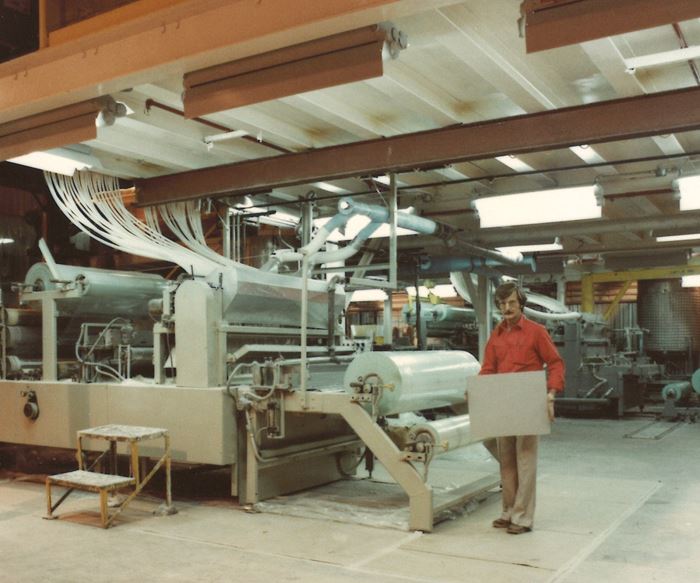

The very first timecard – Clock 1 as it’s called – at the Van Wert facility belonged to Don Chiles, who began working at the plant in June 1978 as a maintenance worker. Chiles, who received electronics training while serving in the Army, had been employed as contract worker by The Budd Company, installing the electronic controls on the SMC lines within the Van Wert facility, before he was hired full time for the plant. The plant opened for production about a month after Chiles came on board full-time. In the early years, the facility compounded approximately 10 to 12 million lb of SMC annually.

“Very early on, we had one SMC line, and were running one shift, two days per week,” Chiles explains. “Not too many of us knew a lot about compounding, so there was a big learning curve. As business grew, we eventually added shifts and SMC lines.”

When Gary Grossheim started at Van Wert as the plant manager in 1983, the facility had two SMC lines, running one shift, five days a week. “We supplied the raw material needs for the division and ended up putting three presses in the plant in the late eighties,” he explains. “We used the presses to mold some car parts, such as bumper beams for Mazda. We also supplied secondary parts for the North Baltimore plant.”

One of those secondary parts, according to Chiles, was water skis. At the time, the Budd Plastics Division owned Connelly, a maker of water skis, so Van Wert and the North Baltimore, OH, US facility worked together to produce the skis through the late 1980s.

Through the late 1980s and into the 1990s, the facility continued to grow in terms of capacity – up to three SMC machines and three shifts. “The materials were changing – the formulations – but the process stayed pretty much the same,” says Chiles, who by that time had advanced into engineering, and was off the production floor.

“Our biggest year while I was there as plant manager, we actually produced 94 million lb of SMC,” recalls Grossheim. “We went to a three shift operation, and the third SMC line was actually put in right after I left the plant managers position. But I think the greatest accomplishment was the fact that we met the needs of the division, mainly because of the efforts of our people. And I can’t stress that enough; the people of the Van Wert plant have always been what made it successful.”

The Van Wert facility became part of CSP in 2006, when CSP purchased the ThyssenKrupp Budd’s Plastics Division. Today, the 69,000 square-foot facility employs 85 people on three shifts. In March 2018, they compounded 13.25 million lb of SMC – a one month record for the facility.

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePly stacking, cutting process optimized via automation, smaller footprint

CAMX 2024: Schmidt & Heinzmann customers are able to produce SMC or dry fiber fabric stacks more efficiently thanks to the AutoCut Pick&Place system.

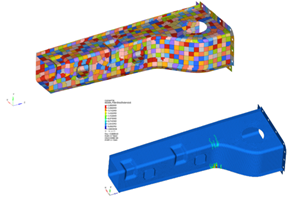

Read MoreSMC simulation tool enhances design optimization

CAMX 2023: FiRMA, Engenuity’s new approach to SMC, uses a predictive technique that accurately reflects material properties and determine the performance range an SMC part or structure will exhibit.

Read MoreMar-Bal expands SMC expertise through AltraSet materials division

The BMC company aims to fill the SMC market gap for those seeking optimal, low-volume demand with custom formulation and high material value.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More