Disruptive composite infrastructure

FiberCore Europe claims the "Holy Grail" of delamination-resistant FRP bridge and infrastructure components with its patented InfraCore technology.

|

|

FiberCore Europe’s InfraCore Inside composite technology enables this 142m span bridge/viaduct over the A27 motorway near Utrecht (left) and 13m tall by 6m wide lock gates in the Wilhelminakanaal near Tilburg (right). SOURCE: FIberCore Europe

Established in 2008, FiberCore Europe (FCE, Rotterdam, Netherlands) has produced over 500 fiber-reinforced composite bridge and lock gate structures worldwide. Among its impressive claims:

- Quick production (one bridge per week)

- Cost parity with steel construction

- First biocomposite bridge

- Composite bridge deck rated for 60,000-kg traffic load (currently highest load class in European design codes)

- World’s largest FRP lock gates

and fiber-reinforced plastic (FRP) structures that won’t crack, debond or delaminate thanks to its patented InfraCore Inside technology.

The company also claimed the world’s largest infusion — 6,200 kg of resin in one shot — in 2009. (The Oyster 125 sailboat hull broke this in 2010 with a single shot of 6,300-kg and a 62m Russian minesweeper hull used two shots in 2011, one totaling 14,685 kg). The company has since infused 6.2m-wide deck sections for the A27 hybrid bridge/viaduct (see below) that used 10.2 metric tonnes of resin in a single shot.

FiberCore Europe completes longest FRP-decked hybrid bridge over A27 motorway near Utrecht. SOURCE: FiberCore Europe.

Hybrid Steel-Composite Construction

FCE also won the Outstanding Paper Award 2015 from the International Association for Bridge and Structural Engineering (IABSE, c/o ETH Zurich, Zurich, Switzerland) for "Hybrid Bridge Structure Composed of Fibre Reinforced Polymers and Steel" which describes design and construction of the 142m span hybrid steel/composite bridge across the A27 motorway near Utrecht, the Netherlands. Comprised of seven prefabricated InfraCore composite bridge deck segments joined and subsequently coupled to a steel support truss to achieve a EuroCode traffic rating of 60 metric tonnes (60,000 kg), the deck weighed only 140 kg/m2 compared to 220 kg/m2 for a steel deck, saving 72,000 kg. The InfraCore deck sections were molded to include not only accurately-dimensioned recesses for slotting connections, but also a water drainage gutter and integrated cable tray. Dry noncrimp E-glass fabrics and foam core — the latter acts as a mandrel and is not structural — were infused with polyester resin per a design that orients fibers in multiple directions to provide a semi-plastic failure mode with redundant load paths for residual load bearing capacity. Fabrication were achieved quickly and cost-effectively at the project site with minimal disruption to traffic — only portions of two subsequent evenings, as self-propelled modular transporters moved the completed span into place.

“The news here is the size,” says FCE founder Simon de Jong. “We had to realize a 71m span between supports, which was not possible with FRP only. So we combined an FRP deck with a steel truss as the primary load-bearing structure, achieving an overall weight savings of 800 metric tonnes vs. the concrete bridge used before.” De Jong points out that this composite bridgedeck’s 60-tonne traffic rating is also a first, and made possible by the company’s InfraCore system.

InfraCore as Backstory

“In 1997, my associate Jan Peeters designed and built the first FRP bridge in Nederland,” recalls De Jong. He notes that hundreds of bridges and other infrastructure were built using FRP in the 1990s. “But then many of these structures cracked and delaminated,” says De Jong. He explains that the Rijkswaterstaat, part of the Dutch Ministry of Infrastructure and the Environment (Utrecht, Netherlands), was very interested in using composites in infrastructure but advised it wasn’t possible “unless you solve this problem of delamination, debonding and cracking.” Now FiberCore Europe’s chief technology officer, Jan Peeters had worked with aerospace composites at TU Delft (Delft, Netherlands), which would prove useful as he began developing a more robust design solution. “The problem was the weakness after impact loading in combination with fatigue due to rolling wheels,” says Peeters. “In sandwich construction, the skin bounces back, but the core material and/or beams underneath are no longer connected to the skin. Subsequent loading from truck wheels then spread this delamination.”

With InfraCore, there is no adhesive bonding between the core and skin. The polyurethane foam core acts only as a permanent formwork and is not structural. The skin-stringer construction thus, is not formed by box beams glued to faceskins, but instead by multiple Z-shaped two-flanged web structures which are overlapped and then faced to form an extremely robust construction. “There is no longer a resin-dominated crack area,” says Peeters. “The fibers in the upper and lower skins and in the reinforcing ribs run in all directions seamlessly so that local damage cannot extend.” A feat, he claims, that even bridges using composite pultrusions cannot achieve. The durability endowed by InfraCore has been proven by large-scale laboratory tests at TU Delft, where 1:1 scale bridge deck sections were tested in three-point bending at loads up to 45 tonnes with no failure. In further testing, the InfraCore deck section was impact damaged locally to simulate a cargo container drop, and then areas at the size of wheel prints were loaded up to 13.5 tonnes, as part of the typical load pattern of a vehicle weighing 60 tonnes. After 30 million cycles, there was no propagation of damage and the strength and stiffness were the same vs. pre-damage evaluation. “This simulates a service life of over 100 years,” says De Jong.

|

|

The reduced weight of the 13m tall by 6m wide FRP lock gates in the Wilhelminakanaal reduce friction and load on the actuation system during gate operation as well as much lower maintenance costs. SOURCE: FiberCore Europe.

Extended Benefits

This same construction used for a helicopter deck on a luxury yacht has shown excellent fire resistance performance in improvised tests by Lloyds Register (London, UK). It also absorbs energy well, showing potential benefits in fenders and other structures for large ships. Meanwhile, eight FRP lock gates, measuring 13m tall, 6m wide and bridging an 8m difference in water height, have been installed in the Wilhelminakanaal (Tilburg, Netherlands) for the client Rijkswaterstaat. Touted by FiberCore Europe as the largest FRP lock gates in the world, their composite construction offers reduced weight and accordingly reduced friction in gate operation, resulting in less load on the actuating mechanism. They also provide a 100-year service life with much reduced maintenance costs vs. traditional materials, and increased sustainability including less CO2 emissions during production.

Rijkswaterstaat made a presentation on the FRP lock gates at the 7th International PIANC-SMART Rivers Conference (Sep. 7-11, 2015, Buenos Aires, Argentina). The audience of water authorities and international businesses responded so enthusiastically, that the event organizer PIANC (the World Association for Waterborne Transport Infrastructure, Brussels, Belgium) was prompted to establish the international working group: Composites for Hydraulic Structures.

Another benefit of InfraCore is its potential for cost-savings in bridge renovation. There are roughly one million bridges in the EU that require renovation at an estimated cost totaling 50 billion Euros. “We have engineered a renovation process with InfraCore that could save more than 10% of this, or 7 billion Euros” says De Jong. FIberCore Europe will complete engineering and testing over the next two years in order to validate this financial savings as part of the SUREBRIDGE project, one of only nine infrastructure innovation projects chosen from 100 candidates to be completed within the multinational INFRAVATION program. Organizations worldwide will be watching the results of this program, including the US Army Corps of Engineers and Federal Highway Administration.

|

|

|

|

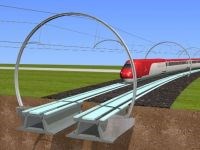

FiberCore Europe is using the InfraCore technology to continue innovating future infrastructure, including bridges with integrated lighting (top and bottom right), floating roadways (bottom left), and FRP catenary systems for high-speed trains (top left) where the whole structure acts as an insulator, eliminating the need for insulating and voltage limiting devices which also reduces stray currents. The high strength of composites enables novel designs with fewer parts and their lighter weight allow for simpler foundations, for overall systems that are easier and faster to install. The environmental costs are significantly reduced with zinc or paint no longer required for conservation and minimal need for maintenance and inspection.

Related Content

PUR composite sandwich panels for 3D automotive parts, high-volume panels and more

At its U.S. sites, Ascorium produces glass fiber/PUR 3D parts via semi-automated molding, high-volume flat panels via a continuous line while working toward bio-based PUR and recycling.

Read MoreKCARBON and KIST develop lyocell/PLA/wood biocomposites

Initial demonstration in furniture shows properties two to nine times higher than plywood, OOA molding for uniquely shaped components.

Read MoreOkom wrks labs works with Autodesk for mycelium-based composite commercialization

Research Residency program will further refine material properties and manufacturing processes to support the startup’s efforts of providing high-performance, regenerative biocomposite solutions.

Read MoreDuplicor biocomposite cladding aids redevelopment of ABN AMRO office building in Amsterdam

Chosen for low CO2 footprint, RC value >9, fire resistance, light weight and high strength, Duplicor façade structures are key to two-story extension.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More