Orbital Composites wins award from U.S. Space Force to build space factories for antennas

Partners Axiom Space, Northrop Grumman Space Logistics and Southwest Research Institute will help advance ISAM technologies for kilometer-scale LEO antennas, space stations and GEO applications, targeting space factory in 3-5 years.

Share

Read Next

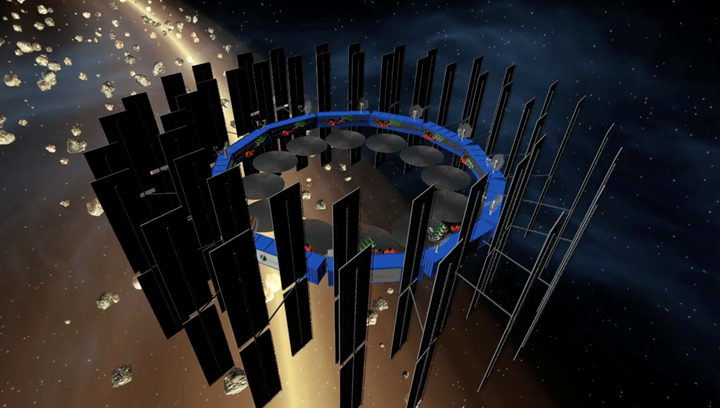

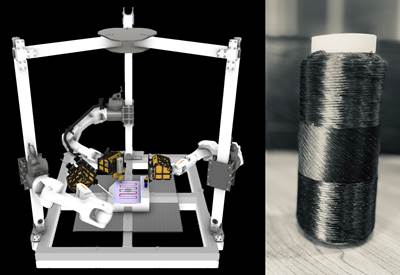

In this rendering, antenna structures with composite frames are manufactured in space from containerized units (blue) leveraging Orbital Composites’ innovative 3D printing, advanced robotics and autonomous system technologies. Photo Credit: Orbital Composites

Orbital Composites (Campbell, Calif., U.S.), a deep-tech startup pioneering in-space manufacturing technologies, has been awarded a $1.7 million contract by the U.S. Space Force (USSF) innovation arm, SpaceWERX and its Orbital Prime initiative to accelerate technologies for in-space servicing, assembly and manufacturing (ISAM) that enable a sustainable space infrastructure and an open and prosperous space domain.

Orbital Composites has been awarded a Direct-to-Phase-II Small Business Innovation Research (SBIR) grant in collaboration with key U.S. industry players including Axiom Space (Houston, Texas, U.S.), Northrop Grumman (Denver, Colo., U.S.) and Southwest Research Institute (SwRI, San Antonio, Texas, U.S.). Within this program, Orbital Composites says it will revolutionize two critical applications: satellite-based cellular broadband (SBCB) and space-based solar power (SBSP), providing universal access to broadband internet and clean energy worldwide.

“Orbital envisions a future where space infrastructure is no longer bound by the limitations of traditional earth-based manufacturing and assembly methods,” says Amolak Badesha, cofounder and CEO of Orbital Composites. “Our robotic ISAM platform represents a quantum leap in the way we construct and maintain space-based structures. Through cutting-edge 3D printing technology and advanced robotics, Orbital Composites is unlocking unprecedented possibilities for scientific advancement, national security and commercial space ventures.”

According to Cole Nielsen, founder and CTO of Orbital Composites, the company’s space factories “will leverage advanced robotics and autonomous systems to build high-performance antennas in space, reducing the cost by more than 100 times.”

In-space manufacturing for first commercial LEO space station

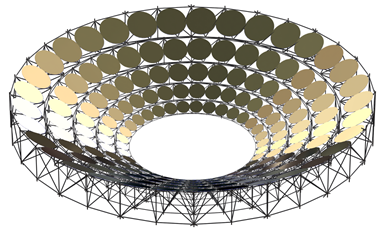

Badesha and Nielsen explain that large antennas are needed for SBCB, and exceptionally large (kilometer-scale) antennas are needed for SBSP. Both applications require high-volume and low-cost manufacturing processes and ISAM capabilities. Orbital Composites’ approach is to directly manufacture and assemble such antennas in space, offering the potential to dramatically reduce deployment cost and enable new disruptive commercial opportunities. Already in 2023, Orbital signed a memorandum of understanding (MOU) with Virtus Solis (Troy, Mich., U.S.) to build the first MW-scale SBSP station.

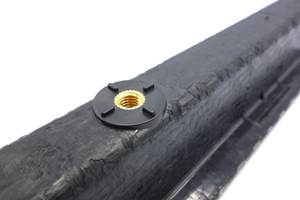

A 3D-printed composite frame provides the strong yet lightweight support for reflectors in a space antenna. Photo Credit: Orbital Composites

A strategic partnership with Axiom Space is key to Orbital Composites’ vision, says Badesha. As a front-runner in the race to build commercial space stations in low Earth orbit (LEO), Axiom Space has a vested interest in ISAM. Orbital Composites and Axiom Space are exploring the development of an Orbital ISAM “laboratory” on Axiom Station, targeting what is claimed will be the world’s first commercial space station in LEO. The two companies will also explore potential applications for ISAM like antennas and even building parts of the future space station itself.

“The future of the in-space economy relies on large-scale, in-space manufacturing and assembly,” says Jason Aspiotis, director of in-space infrastructure and logistics at Axiom Space. “Partnering with Orbital Composites, a leader in this field, allows us to nurture the development of these vital technologies. The strategic partnership offers both companies a chance to accelerate their shared mission of advancing humanity’s presence in space.”

Beyond LEO, Orbital Composites is already planning to develop ISAM capabilities for geosynchronous orbit (GEO). Space Logistics, a Northrop Grumman subsidiary, has developed in-space servicing of GEO satellites using its fleet of commercial vehicles including the mission extension vehicle (MEV), the mission robotic vehicle (MRV) and the mission extension pod (MEP). Space Logistics will lend its expertise to help refine Orbital Composites’ antenna space factory for GEO.

Another key partner in the project is SwRI, with decades of experience in advanced robotics and space. “ISAM is important for the development and utilization of space,” says Branson Brockschmidt, senior robotics research engineer at SwRI. “In partnering with Orbital Composites on this SpaceWERX Orbital Prime SBIR, we intend to design and test systems in vacuum and thermal conditions to advance robotic ISAM.”

With this Direct-to-Phase-II SBIR award from the USSF, Orbital Composites will expedite the development of its advanced manufacturing technologies, with plans to launch its first space factory module within the next 3-5 years.

Related Content

Robotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreRead Next

Orbital Composites to demonstrate containerized 3D printing robots for AM wind blade manufacture

Project aims to demonstrate additive manufacturing of >100-meter-long composite wind blades with >25% reduced cost.

Read MoreOrbital Composites installs robotic AM system at University of Rhode Island

The 12-axis Orbital S system designed to print continuous fiber-reinforced parts will be used to advance research in composites for underwater unmanned vehicles.

Read MoreOrbital Composites, ORNL collaborate to advance robotic polymer and composite AM

The research will focus on the development of a commercially-ready system capable of robotic overprinting on pre-manufactured non-planar surfaces, with multi-material polymers and continuous fiber.

Read More