EAA AirVenture 2009: The theme was BIG

HPC’s on-the-runway reporter, Tom Fay, follows up our September 2009 news coverage with a look back at (and background on) select composite craft on view at the past year’s "Oshkosh Fly-In."

Share

Once the playground of the Experimental aviation crowd, the EAA AirVenture (July 27-Aug. 2, Oshkosh, Wis.) is today a galactic event, with innumerable worlds to explore. Nowhere else can you find a show that so accurately mirrors every facet of aviation.

This diversity meant that space at AeroShell Square, the show’s main display ramp, was at a premium at EAA AirVenture '09. Not only because of the number of display aircraft but also the sheer size of several noteworthy examples. Most noticeable was the Airbus A380. Airbus (Toulouse, France) has been showing its “Jumbeaux Jet” around for some time, so it was only natural that world’s biggest airliner would show up at the “World’s Biggest Aviation Celebration.” A crowd magnet all week, it easily ate up a fourth of the main display ramp. Its composite vertical tail towered above everything else, even the old, yellow-brick Wittman Airport aircraft traffic control tower. We’ve seen the photos and read the specs but they don’t even begin to convey the magnitude of the thing. When parked, it’s as much a place as a plane — many cracked jokes about giving the thing its own zip code. Although Boeing’s 50 percent composite 787, which took to the air (finally) just as this article was published, has stolen a bit of the A380’s glory in this industry, we shouldn’t forget that the current surge in the use of commercial aircraft composites began when Airbus committed to 16 percent composites in the A380’s airframe.

And just to make sure the ramp was packed to the gunwales, they tossed in a C-5A, which flies a massive composite tail structure.

Composites in space

Nearby was Scaled Composites LLC (Mojave, Calif.) WhiteKnightTwo (WK2) which made several demo flights during the week (also see second item under "Editor's Picks," at right). The company claims it’s the world’s largest all-composite aircraft, and they’re probably right. Its wing spans more than 140 ft/12.2m and its twin fuselages are each about 60 ft/18.3m long and tall enough inside to walk around in. Scaled helmsman Burt Rutan and fledgling U.K.-based space tourism firm Virgin Galactic’s Sir Richard Branson have come a long way since Rutan and partner, Microsoft cofounder Paul Allen, watched pilots Mike Melville and Brian Binnie ferry SpaceShipOne to launch altitude via WK1, then saw the craft reach a apogee of 100 km/62 miles altitude — well beyond the boundary of atmospheric flight — twice within two weeks to capture the Ansari X PRIZE for the first privately funded suborbital space flight. It cost about $20 million to win the $10 million prize, but from very early on, the plan was to make space flight pay its own way: WK2 is designed to carry SpaceShipTwo, a much larger six-passenger suborbital craft, to the edge of space, full of fare-paying private citizens (many flights are already booked, see last item in “Editor's Picks”).

WK2 is an interesting aircraft, structurally, with a one-piece spar going from wingtip to wingtip. The caps are carbon fiber pultrusions. This is very similar to a dummy, Formula-One-sized spar built in the late 1980s by the late Tom Tellefson with the assistance of the author. In that case, an aluminum channel was used as a tool to lay up plain-weave E-glass +/-45° to the longitudinal axis. We made two “C” sections this way, then bonded them, back to back, over a slab of ROHACELL foam (DIAB Americas LP, DeSoto, Texas). Then the carbon caps were added in the form of thin pultrusions from Diversified Fabricators. (It’s founder, Stan Prosen, had gotten fiber content up to 80 percent.) Starting with a full length strip, going from root to tip, progressively shorter strips were added to the stack and trimmed to shape. The spar caps for the WK2 are quite similar in construction, but larger and much longer. It is said to be the longest one-piece aircraft component ever made entirely from composites.

The wing’s planform is constant chord except for the outer panels, which are best termed semi-elliptical. Another unusual feature is that its two fuselages are joined by the wing alone. Unlike other twin-boom and twin-fuselage arrangements (P-38, OV-10, Cessna 337, F-82 Twin Mustang, etc.), each fuselage on the WK2 has its own complete tailgroup, unconnected to the other in any way. This inevitably increases the torsional load on the center wing. But the flight crew swears up and down that the plane’s capable of aerobatics. Although we’re pretty sure they limit the horseplay to loops and rolls, its no doubt sturdy enough — Rutan’s myriad composite aircraft designs are known for a lot of things, but structural failures and breakups aren’t among them.

Its fuselage interiors were bare at Oshkosh, allowing a better look at the way the parts go together. There aren’t a lot of interior reinforcements. A handful of longerons and maybe a half-dozen formers and bulkheads, as would be expected in a honeycomb sandwich structure. This is a pressurized, high-altitude platform, so the windows are necessarily rather thick, and it looked as if glass fiber, or maybe aramid, doublers were used around the window cutouts.

SpaceShipTwo should be ready to fly commercially by 2012. Rumor is, however, that the first flight attached to WK2 with paying customers could be undertaken in Oshkosh as early as EEA AirVenture 2011.

Green flying machines

Whether or not one buys into the global warming theory, there are plenty of good reasons for alternative energy use, not the least of which is less dependence on outside sources of aviation fuel (oil). Photovoltaics are the pinnacle of autonomy (as long as the sun is shining), and their potential as an alternative power source for aircraft was demonstrated in Oshkosh as early as the 1980s, when an Easy Riser ultralight dubbed SolaRiser was flown for about a minute. A baby step, but a start. So it was only a matter of time until a viable electric plane showed up. That day came at AirVenture 2009, when Yuneec International (Herts, U.K. and Shanghai, China), brought in its E-430 electric motorglider. The aircraft was first flown on June 12, 2009, and on July 18, it was given an airworthiness certificate by the FAA.

It was big news. A soaring machine, it has a lot of wing — the 22.9 ft/7m craft has a 45.2 ft/13.8m wingspan — but, the lightweight all-composite airframe weighs only 551 lb/250 kg. The craft uses lithium polymer battery packs (charge time is three hours), also manufactured by the Anglo-Chinese venture. It can use 6 or 10 packs, depending on mission requirements. Oddly enough, it has a maximum takeoff weight of 946 lb/429 kg with six batteries, but only 1,034 lb/469 kg with 10. (Each pack weighs 28.5 lb/12.9 kg). So the extra power available with 10 packs more than makes up for the increase in weight over six.

Flight duration with six is said to be 1.5 to 2 hours, but a competent sailplane pilot could glide from one thermal to the next for hundreds of miles, conditions permitting, using power only when absolutely necessary. Yuneec estimates that the price of a commercially available LSA production version will be $89,000 (USD).

Bigger B for border patrol

The U.S. Customs and Border Protection Service brought in a General Atomics Aeronautical Systems (San Diego, Calif.) Predator B UAV (unmanned aerial vehicle) used primarily for border surveillance and drug interdiction. The aircraft itself is fairly straightforward, with a carbon fiber airframe that is quite similar to a lot of the composite homebuilt kits of the last 30 years.

Although the people at General Atomics were very pleasant to chat with, they were very closed-mouthed about details of the Predator B airframe. We can surmise that it’s probably pretty conventional (uni spar caps, woven skins, few ribs — the usual stuff you’ll find in any homebuilt composite airframe).

It’s 9 ft/2.74m longer than the original Predator, with 36 ft/10.9m vs. 27 ft/8.2m overall length, and a 66 ft/20.1m span as opposed to the older item’s 55 ft/16.8m. It’s also much heavier, with a max gross takeoff weight of 10,500 lb/4763 kg vs. the original’s 2,300 lb/1,043 kg. All of that extra wetted area (read drag) and weight requires a bigger rubber band to make it fly, and that it has. The older version could stay aloft for 40 hours powered by the ubiquitous Rotax 914, a 120-hp turbocharged version of the Rotax 912 seen in most LSAs. In the Predator B, they went with a Honeywell (Garret) TPE-331-10T in the 750-hp class. Despite this gargantuan jump in power, it can fly missions of more than 30 hours duration. The Predator family opened the door to the concept of armed UAVs, and the 3,800 lb/1,724 kg payload afforded by the Predator B translates into a large rack of Hellfire missiles.

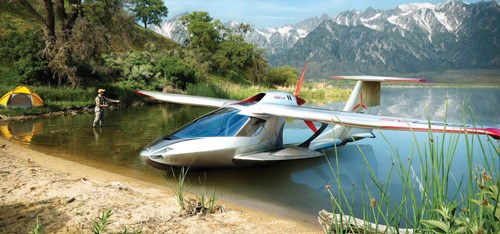

Big splash for a sporty amphibian

On static display last year, the Icon A-5 amphibian was demonstrated at the air show site and the EAA seaplane base on nearby Lake Winnebago. With sleek aerodynamics lines, automobile-like landing and taxi lights and an instrument panel more like that in a Lamborghini supercar, it makes a big first impression. Although no specific materials for the production version have been called out, the folks at Icon Aircraft (Los Angeles, Calif.) tell us that the bulk of the airframe is carbon fiber. In the case of the prototype on view, some wet layups were used, but this will no doubt be minimized during development, with prepregs predominating. The “T” tail’s horizontal stabilizer consists of one-piece top and bottom skins, with a spar and ribs in between, much like a wing. The wing is fairly conventional, with a top skin molded in one piece, and the spars, ribs and control linkage are installed, with the structural components secondarily bonded. The bottom skin is molded separately, and bonded onto the underlying structure. The wings are hinged and fold back along the fuselage just outboard of the center section (the exact break may change in the production model). The main spar is staggered to permit folding the wing. The outer spars are joined to the center section spar for flight with two large pins per wing.

The fuselage is laid up in right and left halves, which include the vertical tail and engine/wing mount cabane structure aft of the cockpit. The halves are adhesively bonded, and then carbon fiber windshield posts are installed, along with the wing center section and one-piece engine cowling/scoop. Last on are the sponsons (Icon calls them “seawings”), which protrude several feet from the fuselage, half above/half below the waterline, and likely will contain fuel and some storage space as well.

The Icon team has quite a way to go before production aircraft can roll out the door, but many of the company’s engineers are alums of Scaled Composites, a place where starting with a clean sheet of paper and flying a prototype a few months later was the modus operandi. So there’s little doubt they’ll pull it off. The A5 will be aimed toward the upper end of the S-LSA market, with a price tag in the $140K range.

Another big splash at EAA

A much larger entry in the seaplane market was the Domier CD-2 Seastar from Domier Seaplane Co. (Punta Gorda, Fla.). Like the Icon A5, It’s of all-composite construction (carbon fiber and glass). Unlike the Icon, it can seat up to 12 passengers and a crew of two, although a more realistic six-to-eight passenger arrangement is more likely in actual service. It has a wingspan of 58 ft/17.7m, and is of glass and carbon construction. Maximum takeoff weight is 10,141 lb/4,600 kg, but useful load (fuel, passengers and baggage) is 2,910 lb/1,320 kg. Not a really good ratio, but seaplanes are a compromise to begin with, and efficiency is not generally their strong suit. Power comes from two Pratt & Whitney Canada PT6A-135A turboprops flat rated at 650-hp each. Like many Dornier seaplanes, the engines are mounted in a nacelle above the fuselage, in push/pull fashion. The cabane structure that supports the wing and nacelles is a truss not unlike the center attachments on biplane wings of the 1920s and ‘30s, made then with short lengths of streamlined aluminum tubing. Even though streamline tubing is strong stuff, the structure has to support not only the weight of the powerplants but withstand the combined thrust of the engines as well. (It reminded me of Dornier’s Do-X flying boat (circa. 1930), which had 12 Curtiss Conqueror engines arranged push-pull style in six similarly mounted nacelles, with a virtual jungle of struts and wires atop the wing.)

The aircraft and its builder have an interesting history: Prof. Dr.-Ing. Claude Dornier founded the company in 1910, and immediately became interested in flying boats, with designs ranging from small, single-seaters (little more than today’s Ultralights) to the above-mentioned 167-seat Do-X. In the ‘20s, his efforts were directed primarily toward coming up with a competitor to win some of the lucrative mail and passenger routes that were being established worldwide, which culminated in the Do-X touring the routes and giving demo flights to various potential customers. Alas, it found itself eclipsed by the Martin and Boeing “Clippers,” and the political climate around Europe, especially Germany, was such that during World War II, his efforts shifted to warplanes, including a large flying boat in the same category as the USA’s PBY, and the very fast, push-pull, twin-engine Do-335 fighter. After the war, the company became Dornier GmbH and expanded with projects as diverse as a turboprop regional airliner and an open-air, single-seat helicopter, with Prof. Claudius Dornier, Jr. at the helm, who steered the company through many developments, including partnerships with Fairchild (an airliner) and Dassault (the Alpha Jet).

In 1982, the professor retired as chairman of what was, by then, a very large multinational conglomerate, and returned to seaplane design, launching the an all-composite amphibian, the Seastar, a modernized (read compositized) version of the Wal (German for whale), a similarly sized flying boat from the early 1920s. In the early ‘90s, there was a squabble over who owned the rights to the airplane. In the ensuing litigation, the bulk of the company fell to Fairchild, but Dornier Jr. kept the Seastar and finally begat the Dornier Seaplane Co. Nowadays, Conrado Dornier, grandson of the founder, is at the helm.

The plane will be built and marketed in the U.S., but engineering will remain in Germany. Most of the components were made with wet layup – no vacuum bags, no bladders. They’ve gone through the time and expense of putting it through the U.S. Federal Aviation Admin.’s (FAA) FAR Part 23 certification. They’re venturing forth with a modernization of an 80-odd-year old-concept. It will likely prove to be a rugged, dependable machine, true to its heritage. For a plane in this class, the only competition is the old Grumman Goose, which can’t be purchased new. On the other hand, the craft holds a $6 million price tag. Will they have follow-on models? This will be interesting to watch.

Return of the roadable aircraft

Also on static display in 2008 but in the air in 2009 was the Terrafugia (Woburn, Mass.) Transition, which its makers insist is not a “flying car” but a “roadable aircraft.” It drew a big crowd that might have included a good number of skeptics. After all, many have tried to pursue the dream of “an airplane in every garage,” without success (see "Editor's Picks," at right). The Transition does fly, but it remains to be seen whether or not the concept flies with the aircraft-buying public. Terrafugia wouldn’t talk construction specifics but did reveal that the primary structure is carbon prepreg, supplied by JD Lincoln (Costa Mesa, Calif.). Its wings feature a bi-fold mechanism: They hinge up at the root, then fold down at midspan. When they’re folded for driving, they’re exposed to side impact damage. (A car with a dented door can still be driven. Not so a flying car with a damaged wing.) The four-bladed prop, however, is well protected, from below, by a sort of rear deck, which is integral with the somewhat understated tail booms. This deck culminates in a large elevator, which also is vulnerable, at the extreme rear of the machine. One bump from behind at a stoplight and it’s grounded.

Related Content

3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More