Experienced Aerospace Manufacturer Relies On Proven Methods

Composite Structures LLC employs metal bond techniques for high-performance aircraft and rotorcraft components.

The concept of marrying metal and composite materials to create aerospace components dates from the early 1950s. The metal bonding process, in which metal parts are adhesively integrated with prepreg and/or honeycomb core and cured, is still used to make a wide variety of aerospace structural parts such as flaps, spoilers, rotor blades, interior bulkheads and even entire wings. The process offers advantages, such as good impact resistance and repairability, as well as good strength-to-weight ratio, despite higher weight compared to composites-only structures. Adhesive bonding often enables designers to eliminate mechanical fasteners, which means a smoother part surface and better aerodynamic performance.

To successfully combine metal with prepregs and core in a layup, designers must consider the elastic mismatch of the two types of materials. The metallic components, or "details," are stiffer than the composite materials they are combined with, says Vicki Winston of The Boeing Co.'s SM&P division. This stiffness difference means the layup has less flexibility, which makes the fit tolerances of the components very important. Misfitted details can inhibit part consolidation during vacuum bagging and autoclaving, resulting in hard-to-detect voids and consequent loss of strength.

Suppliers have continued to develop new adhesives over the years to improve the metal-to-composite bond. But, even with improved materials, it remains critical to eliminate contamination — such as oils and grinding residues — from the surface of the metal details, so that the adhesive will bond properly.

Composite Structures LLC (Monrovia, Calif., U.S.A.), founded in 1953 as Monrovia Aviation, is one of the oldest and largest aerospace manufacturers specializing in metal bonding. Formed in 1849, its parent Ducommun Inc. (Long Beach, Calif., U.S.A.) is the oldest company in California and was one of the first suppliers of aircraft aluminum to the fledgling aircraft industry. Composite Structures' metal bonding expertise is an integral part of Ducommun AeroStructures, which also includes AHF-Ducommun (aluminum stretch forming and tooling), Aerochem Inc. (chemical milling of metals) and Parsons Precision Products (titanium hot forming, superplastic forming and tooling services). Composite Structures has refined its aerospace part manufacturing operation for half a century in its 300,000 ft2 manufacturing facility 25 miles northeast of Los Angeles.

High-volume, efficient production allows cost-effective manufacture

"We've made more helicopter rotor blades than anyone else in the world, including Boeing, Bell and Sikorsky," says Composite Structures' director of business development Jerry Maxwell. "Our core capability is the manufacture of large, complex metal-and-composite structures."

The company typically builds parts based on designs and specifications furnished by the aircraft's manufacturer. In many cases, parts are long-standing legacy designs. For example, Composite Structures has manufactured more than 40,000 wing spoilers to date for Boeing's 737. When newer programs call for design work, the company usually contracts design services from Aerospace Consultant and Engineering Corp. (Seattle, Wash., U.S.A.), which executes designs using state-of-the-art software.

The manufacturing process starts with the shaping and fabrication of the metal parts, typically made from aluminum, titanium or 300-series stainless steel. In some cases, more exotic metals, such as tungsten, nickel and Inconel alloy, are used. The company has a sheet metal fabrication area and a machine shop, equipped with multiple CNC routers and milling machines.

The metallic parts are then chemically etched in either BAC 5555 phosphoric acid or chromic acid anodizing solution, which deposits a thin, protective oxide coating on the metal in preparation for adhesive bonding. They are then primed with an adhesive epoxy primer (i.e., a paint-like epoxy material) then oven-cured, inspected, and sent to a clean storage area to await layup.

On the composites side, typical materials used in the assemblies include woven prepregs and honeycomb core. Carbon, glass or bismaleimide prepregs are cut, labeled and nested to create a defined layup set, using a Gerber Technology (Tolland, Conn., U.S.A.) computer-controlled cutting table. Honeycomb includes Nomex aramid/phenolic honeycomb made from paper manufactured by DuPont Protection Solutions, (Richmond, Va., U.S.A.) or aluminum. Core materials are machined and shaped to exact dimension with three Cincinnati Milacron (now Cincinnati Machine Inc., Cincinnati, Ohio, U.S.A.) computer-controlled milling machines. The core machining is done in a separate room with its own ventilation system to keep core dust out of fabrication areas.

Each composite material set is kitted with the appropriate metal detail set for a particular part, and both are issued to a technician. Layups occur in Composite Structures' 50,000 ft2 clean room. Smaller parts, like 737 wing spoilers, are fabricated in lightweight, tabletop aluminum layup tools that can be easily transferred to carts. Larger parts, such as the Boeing C-17 spoiler, are made on moveable tooling structures that can be rolled from the clean room into the autoclave. Tools are typically supplied by a Ducommun AeroStructures company, usually AHF-Ducommun (Gardena, Calif., U.S.A.).

If required by a customer contract, technicians at Composite Structures practice "prefit" methods — essentially laying up the part in the tool first, without adhesives — to ensure that the fit is correct and within tolerances. Boeing's Winston says that prefitting is extremely useful in identifying components that may appear to be within specs but may "stack up" in the layup. In other words, slight imperfections can collectively create an out-of-tolerance layup in the tool. While it adds time, Maxwell says that prefitting helps identify problems and significantly reduces the number of rejected parts. Quality control also is enhanced by the recent purchase of a laser projection system that projects the correct sequence of prepreg plies and metallic details onto the layup tools. After prefit, the parts are re-layed up with layers of epoxy film adhesive.

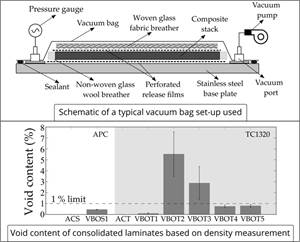

Once the layups are complete, the tools are vacuum bagged with nylon film, then moved to the adjacent autoclave area which houses seven Thermal Equipment Corp. (Torrance, Calif., U.S.A.) autoclaves, each with the capacity to process multiple parts. The bagged layups are claved for approximately five hours to cure the prepregs and film adhesives.

To streamline the manufacturing process for helicopter rotor blades, the company employs a proprietary hybrid process that combines filament winding and bladder molding to create the rotor's fiberglass spars. The shaped spars are combined with Nomex core material and a titanium forging to form the finished rotor.

"Rotor blades represent about 40 percent of our business, and flight control surfaces like spoilers and flaps another 40 percent," says Maxwell. "We've worked hard to make our processes more productive, employing lean manufacturing and continuous improvement methods."

Testing of bond integrity is critical

Because of rigorous performance requirements, process verification testing of parts is critical. Prefit is important but doesn't provide any information on bond line thickness nor does it allow quantification of the force needed to pull the bond apart, says Winston. Composite Structures uses additional verification tests, including ultrasonic non-destructive inspection (NDI), destructive inspection and a technique called verifilming.

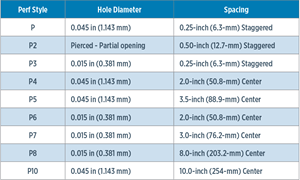

Verifilm testing is essentially part layup, consolidation and cure, but without adhesive bonding. In other words, a test part is layed up with very thin (typically 0.001-inch thick) fluorinated ethylene propylene (FEP) film placed above and below the adhesive film layers, to prevent the adhesive from sticking to the prepared or "faying" metal/composite surfaces. The layup is processed normally, but then disassembled after cure (because the film prevented adhesion) and carefully examined for potential bond line defects. The indentations in the encapsulated adhesive layers verify correct detail fit and help determine if any bond lines are too thick or too thin. While the very thin FEP film can be difficult to work with, especially on contoured parts, verifilm is the only way to determine bond line thickness in parts before actual bonding — NDI can't.

The company's NDI testing equipment includes two large waterjet stations used for "C-Scan" ultrasonic testing. The part is positioned between the waterjets or "squirters," which are placed several inches away from each side of the part, and are aligned so that they shoot a low-pressure column of water on each side of the part. A transmitter induces a sound wave in one water column, which travels through the part and is conducted through the opposite water column where it is received by a sound transducer. Equipment measures the sound loss or attenuation and compares this to an acceptance standard. "A-Scan" works on the same principle as "C-Scan" except that a sound transmitter is placed in direct contact with the part surface via a coupling fluid. The equipment measures the amount of sound reflected back through the part and compares it to a standard. Parts must fall within the acceptable range of sound loss (attenuation) to be considered for production.

Winston explains that for Boeing heritage parts, a standard part is built with intentional bondline voids. The standard part is used to calibrate the NDI equipment to ensure that it can detect the known voids before actual production parts are tested.

Destructive testing involves cutting up a finished part into coupons and visually examining the bondlines for correct thickness. Coupons are then placed in a test fixture and subjected to peel forces to verify that the bonds can handle the design loads. Typically, destructive testing is more frequent at the beginning of a program — but with Composite Structures' more mature contracts, such testing occurs infrequently, says Maxwell. Once tested, parts are carefully packed and shipped to customers in reusable shipping containers designed to protect the parts. The company also is an FAA-approved overhaul and repair facility for structural repair of blades and control surface parts.

Composite Structures recently announced a $7 million contract for an new, all-composite S-61 helicopter main rotor blade for Carson Helicopter, and has received a contract to fabricate an all-composite winglet for the 737. Upcoming F-22 contracts should be announced soon. With its backlog of work for Bell Helicopter Textron, Boeing, Rolls-Royce (for jet fan case blade-containment rings) and others, the company is positioned to combine both old and new composites technologies, for the foreseeable future.

Related Content

TPRC research studies void removal mechanisms in VBO processing

New publication evaluates vacuum bag only-consolidated carbon fiber/PEEK tapes to determine the role of different void removal mechanisms in thermoplastic composites.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MoreEngine vane demonstrates potential for gapped, unidirectional dry fiber for infusion

GKN Aerospace and its partners developed an aircraft demonstrator component made with TeXtreme’s latest Gapped UD material, proving out a dry, infusible tape meant to compare in performance to UD prepreg.

Read MoreCarbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More