February supplement: Out-of-autoclave processing for aero use

We here at CW put together a supplement published with the February issue of the regular magazine that focuses on the technologies, tools and materials being used today in out-of-autoclave (OOA) processing for aerocomposites.

This five-plus passenger, single-engine, V-tailed personal jet will sport an OOA-composites-enabled low maximum takeoff weight of 2,722 kg.

We here at CW put together a supplement published with the February issue of the regular magazine that focuses on the technologies, tools and materials being used today in out-of-autoclave (OOA) processing for aerocomposites. If you're a CW subscriber you will receive the supplement in the mail, but if you're not, or if you don't want to wait for the postal service, you can find the supplement here: cw.epubxp.com/i/630867-autoclave-2016, or just click any of the images.

The A350 XWB window frame preforms, made by Advanced Composite Engineering GmbH, use vertical structural stitching and selective stitching to achieve an L-cross-sectioned oval without any wrinkles and a glass fiber lining to prevent galvanic corrosion in contact with metal.

Although OOA processing in aerospace applications has been employed for decades in the manufacture of thermoset composite parts for unmanned spacecraft and, more recently, in the manufacture of substructures for commercial passenger aircraft, the autoclave remains the curing technology of choice for the world’s large aircraft OEMs, primarily because of its brute strength — its ability to definitively consolidate composite parts and remove the voids that can compromise struc- tural performance. Such robust consolidation, however — <1% void content — comes at a high price in terms of capital expense, operational costs and time. As composites move further into aircraft, it’s clear the autoclave cannot be the only process available to aerocomposites fabricators. Today, OOA alternatives include vacuum bag-only (VBO) prepregs, dry fiber placement, infusion processes (which rely on oven cure), resin transfer molding (RTM) and thermoplastic composites.

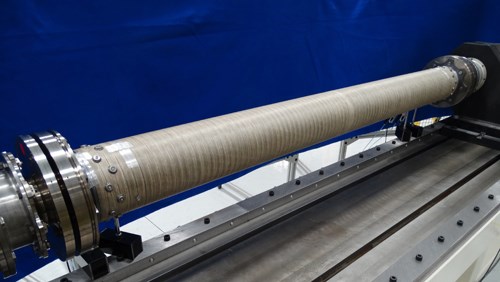

Development of this helicopter driveshaft by Automated Dynamics helped dispel the notion that porosity is paramount when it comes to thermoplastic composites performance. It offered a 35% weight reduction compared to its aluminum predecessor, with 150% post-ballistic torque to failure — with thermoset-unacceptable 4% porosity.

From a technical viewpoint the question is simple: Can OOA options be matured sufficiently to yield parts with <1% void content? The answer, based in part on the reports in this supplement, is yes, but there is a larger question: Can OOA processes match this parameter and demonstrate enough overall savings in capital expense and time to justify the process development/recertification efforts that a move to OOA will require?

At GE Aviation in the UK, a vacuum bagged Upper Panel 12 for the A350 XWB is in oven, ready for cure, with thermocouples (mounted on the underside of the toolface) wired for cure-temperature control.

We may have that answer sooner than later. As the stories in this OOA Supplement demonstrate, the activity level in OOA process development is substantial, involving structures on flying aircraft. And the composites professionals involved with each, as you’ll find, are strongly invested in making OOA not only feasible, but successful.

Related Content

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.