Photo Credit, all images: OCSiAl LLC

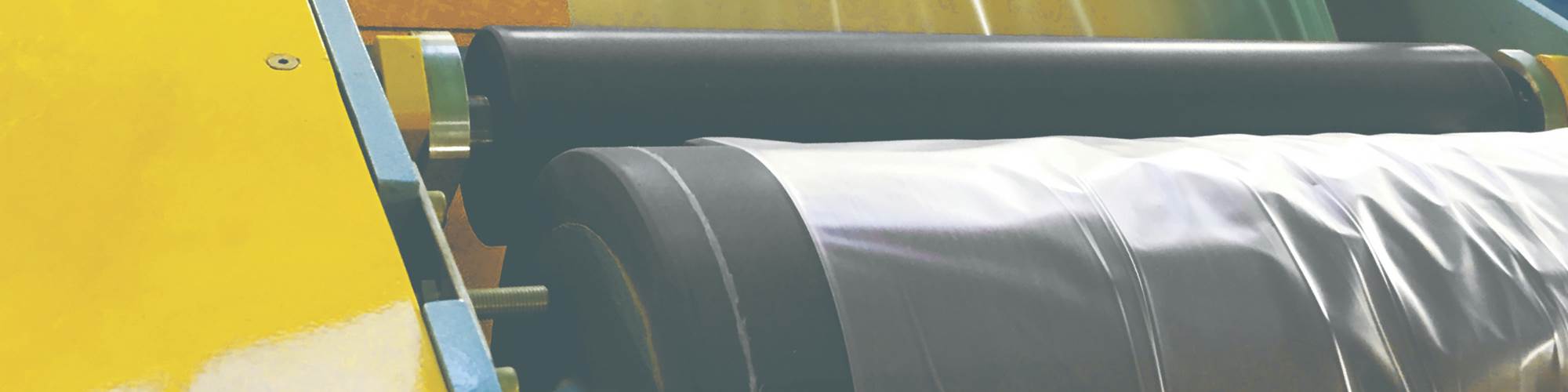

Rotary printing employs the use of high-speed, rotating cylinders covered by a metal or composite conductive sleeve to impress an inked image onto a substrate. One design challenge with filament-wound fiberglass composite sleeves is that these parts produce static electricity during rotation, which can lead to paper sticking, reduced print quality or malfunctions that can slow down the printing process, increase operational costs and pose safety hazards to human operators.

To avoid these challenges, composite sleeves must be modified with an electrically conductive additive to dissipate the accumulated static electricity. Carbon black is a commonly used additive for these types of parts, but a relatively high dosage of the material is required to achieve the needed conductivity, which can negatively impact the mechanical performance of the composite, produce harmful dust and result in dark coloration of the cylinder.

Graphene nanotubes manufacturer OCSiAl (Luxembourg) recently worked with two European printing cylinder producers to integrate pre-dispersed concentrates of its graphene nanotubes into the epoxy of a line of composite printing sleeves. Graphene nanotubes, also called single-wall carbon nanotubes, are one-atom-thick graphene sheets rolled into a tube of more than 5 µm long. According to OCSiAl, these tubes are 100 times stronger than steel, with thermal conductivity three times higher than diamond. They are also five times lighter than copper.

Both customers had previously offered product lines of composite printing sleeves manufactured with carbon black, but were looking for conductive additive options that have fewer negative effects.

According to OCSiAl, its TUBALL graphene nanotubes can be integrated at very low working dosages — starting at 0.01 percentage by weight — thus saving on material costs and increasing the electrical conductivity of the base composite, while avoiding negative side effects like dust production, degradation of mechanical properties or discoloring. The use of carbon nanotubes also is said to enable higher working speed of rotation, and adds flexibility to the production process, enabling the customer to easily adjust product dimensions such as length, thickness and outer diameter while maintaining the correct graphene nanotube dosage.

“The obtained electrical resistivity of less than 107 Ω·cm independent of humidity improves the performance of the new sleeves by dissipating accumulated static electricity,” Phillippe Bichot, technical sales manager for coatings for EMEA at OCSiAl Group, explains. “Weight reduction was achieved due to the overall optimization of the technological process, the coating method and replacing 20 percentage by weight of carbon black with approximately 0.01-0.05 percentage by weight of graphene nanotubes.”

Related Content

-

Carbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

-

Pull-wound carbon fiber poles enable lightweight, compact, rigid emergency stretcher

Based on military feedback, Epsilon Composite developed an optimized, foldable stretcher that combines telescopic pull-wound carbon fiber tubes.

-

Bio-based epoxy, recycled materials increase sustainability of all-terrain snowboards

Aiming for a smaller environmental footprint while maintaining high performance, Salomon’s Highpath snowboard line incorporates bio-based epoxy, glass and basalt fiber stringers and recycled materials.

.jpg;width=70;height=70;mode=crop)