Optimizing, customizing composites hole drilling

Matching the drill tool to the job can save thousands of man-hours and millions of dollars.

Attaching the blended fuselage/wingskin laminate to the airframe on the F-35 Lightning II fighter jet requires accurate drilling of hundreds of fastener holes. Source: AMAMCO

For six decades, “you get what you pay for” has been the marketing mantra for manufacturers and suppliers of composite products who argue that, despite their historically high initial cost, composites are the superior product in terms of overall life-cycle cost. As composites manufacturers increasingly face the need to drill holes in composite components, particularly in the fastener-intense aerospace environment, the shoe is on the other foot.

The time and expense of machining has become a focal point in the struggle to meet delivery schedules and part cost expectations. In response, manufacturers of drill tools are advising the composites industry to take a dose of its own medicine: Customize and realize savings over the life of the program. Although this requires a large initial investment of time and money to study the whole machining process and optimize each machining function, manufacturers of drill tools are claiming worthwhile results, from improved tolerances and reduced operational steps to dramatic surges in workflow, and six-figure annual cost savings.

The problem: Historical lag

Although developments in cutting tool technology have kept pace with those in composites, machine tool marketers tell CW that 80% of composite parts machining is still done with standard, off-the-shelf tools that are not optimized for the materials, the part or the machining setup.

“Companies are purchasing high-cost automated technology to manage increasing demand, but often don’t give their cutting tools a second thought,” says Alex Harding, COO at Cajero Ltd. (Isle of Sheppey, Kent, U.K.). “That means they could be missing out on major improvements, losing huge sums of money and consuming enough energy to power a jet plane.”

The F-35 program demands automated drilling technologies and massive fixtures suitable for “one-up assembly” of stacked but dissimilar materials. Source: AMAMCO

Peter Diamantis, plant manager and tool master at machine tool specialist AMAMCO Tool (Duncan, S.C.), concurs: “Using the wrong tool is almost commonplace within automated machining centers. You would be surprised at how many people are using old technology.” In many cases, their tool selections once were state-of-the-art technology. “They were all developed by a custom tool manufacturer at some point, and became the standard,” he points out, but says their designs were based on studies done years ago. “These studies are outdated now,” Diamantis explains. “These are incredibly smart people, but often they are using older data to choose tools.” Just as important, he adds, the studies don’t address today’s realities. “The materials they were performed on are outdated. Composite materials have changed significantly, even in the past few years.”

Composites, in fact, have become progressively more difficult to machine. Eleanor Merson, who manages composites machining research for the Sandvik Coromant (Amsterdam, The Netherlands) R&D center in Sheffield, U.K., has seen an almost 50% decrease in tool life over the past few years, for a typical uncoated tool used on standard aerospace-grade composite materials. Why? “We are researching that now, trying to understand the interaction between the cutting tool materials and the composites. Overall, we see a general trend that the newer composite materials are harder,” Merson explains, noting that “we are beginning to see that the resin has much more of an effect, which is actually understandable, because it is the resin that is holding the fibers together.” Evolutionary developments in resin formulation now produce harder, tougher matrices. “How the resin breaks apart determines the quality when you cut.” Thus, evolutionary improvement in resins seems to be reducing tool life.

Always a tough nut

Changed or not, composites have always been difficult to machine. Harding explains that unlike in the metalworking industry — where billets made from a homogeneous material to a known standard can be purchased — the composites manufacturer deals with heterogeneous material. Each molder tailors a select combination of resin, fibers/fiber forms and laminate ply sequence that is optimized for each structure and application. The resin system, fiber content, laminate sequence, cure method, cure temperature and laminate integrity each affect part machinability. A further complication, says Diamantis, is that “there are no two shops where everything is exactly the same. Each has a different setup, which can have an adverse effect on performance.”

An aggravating factor today is the labor- and time-saving trend toward drilling stacked materials — that is, pre-assembling composite and metal components in positioning jigs or fixtures, then drilling fastener holes through all the layers in one pass. This technique — often called “one-up assembly” because the components are put together, drilled, inspected and cleaned from the exterior, but are not taken apart again — is a safeguard against inaccuracy of hole positions and saves countless hours. But it presents a huge challenge to those who design drill tools. “It is quite common to see machining through one stack of materials made from carbon fiber-reinforced polymer (CFRP), aluminum, CFRP and then titanium, in that order,” says Merson. “It is extremely difficult to optimize a drill for two or three different materials.”

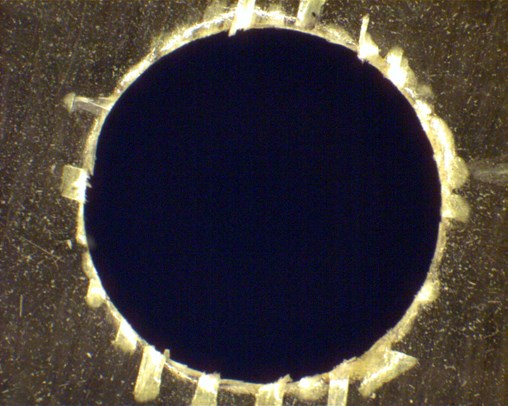

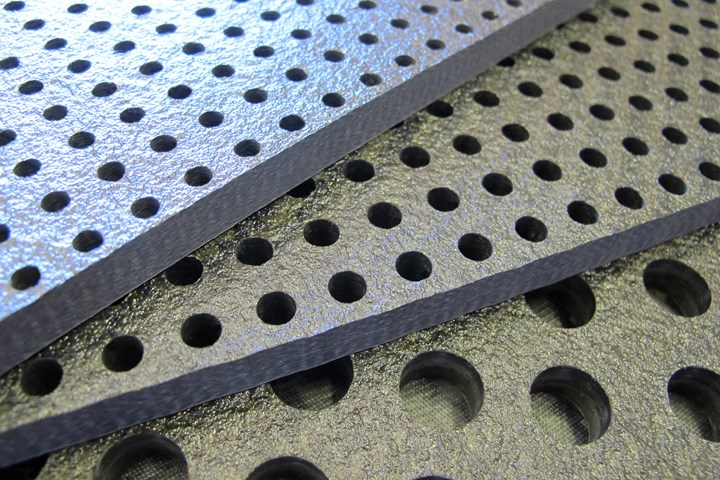

Despite the availability of much better options, machine tool makers say most drilling of composites is still done with “standard” tools that once were state-of-the-art but now — because they are not optimized for the material, the part, and the machining setup — are substandard. The result is that drill performance quickly deteriorates and hole quality deteriorates with it. Here is an example of deterioration: splintering. Source: Sandvik Coromant

The solution: Get up to date and communicate

When CW contacted these and other representatives of leading players in the machine tool industry, they came back with a number of problem-solving strategies under two broad headings: optimization and customization.

Composites pros are no strangers to the former. Optimization is a buzzword in composites circles these days. The greatest gains come from looking at the whole process. Drill toolmakers contend that the same is no less true of machining. The materials, fixturing, debris removal, access and worker ergonomics must be considered at the beginning, during part development, rather than at a later stage after major decisions have been made.

“It’s all about understanding the entire machining process,” says Diamantis, noting that it also takes a cooperative customer. “Are the engineers willing to do testing in order to refine the process? Sometimes they rely on a study done years ago and they don’t want to revisit it. Others are willing to do whatever it takes to find the savings.” Harding emphasizes that those who are willing reap great rewards. “We’ve helped companies make huge gains via collaborative productivity partnering programs that challenge conventional wisdom.”

If the partners are to be successful, however, the machine tool manufacturer must understand both the part and the process in detail. Here, no data are insignificant. “Customers are not always detailed enough in explaining to us what they are machining,” says Sandvik Coromant’s Merson. “We need as much detail as possible. We must look at the materials, the curing, the fiber contents, the structure and manufacturing steps involved.”

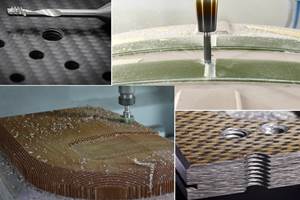

Pictured is another effect of drill deterioration: delamination. Source: Sandvik Coromant

That knowledge permits tool customization, the necessary antidote to a manufacturing discipline that is, itself, all about customized solutions. In brief, the message is Leave the off-the-shelf tools on the shelf. “Many shops want to use off-the-shelf cutting tools, which is okay,” says Diamantis, “but the machining process will take a lot longer and use a lot more tools.” A wise composites manufacturer designs a part for the specific application. It follows that the drill tool ought to be designed both for the part and the application.

No substitute for experience

Toward that end, the composites manufacturer needs the assistance of a toolmaker capable of making such assessments. Merson observes that manufacturers of cutting tools for metals now see an opportunity to diversify into composites. “But what they have traditionally done to increase tool life for cutting metals — for example, reduce feed rate and cutting speed — has the opposite effect for tools cutting composites.” For this and many other applications, Sandvik Coromant works closely with its recently acquired partner Precorp (Spanish Fork, Utah, U.S.), a long-time specialist in composite drill tools, to deliver state-of-the-art cobranded drills and milling cutters.

The message? What works with metals does not work with composites. “The drill tools for metals and those for composites are completely different,” says Diamantis.

The abrasive nature of carbon fiber makes it unlike any other material that cutting tools encounter, thus the importance of tool life is critical and heavily emphasized by many who supply drill tools to the composites industry.

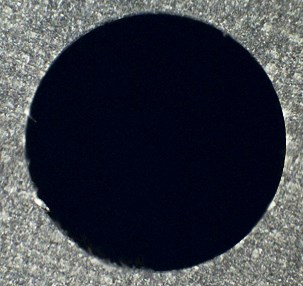

Here is a close-up of a hole drilled with an undamaged drill tool. Source: Sandvik Coromant

Exploiting new geometries

Twenty years ago, cutting tool optimization basically consisted of developing geometries that could more effectively machine each type of fiber. It is standard today for cutting tool suppliers to offer tools with specific geometries optimized for aramid, glass and carbon fiber. But today, optimizing goes well beyond looking at the fibers. Says Diamantis, “We must understand the entire process in order to design the proper tool geometry. What is the setup like? Can you use coolant? What is the drill type, drill motor, power feed? Is the drilling robotic or by hand? Are you drilling in one operation or two?”

Harding summarizes some of Cajero’s R&D findings: “Geometries that are progressive — develop gradually — and reduce pressure at the center work well with composites because they reduce cutting thrust forces, which helps to avoid delamination and damage on break through. These geometries also must maintain a positive shear angle — which keeps cutting forces low so that material is removed with minimal pressure and provides an easy path for the debris to exit the hole.” Harding lists a number of tool geometries for different types of composites:

Multifacet drill points have double-angled points — that is, the lead angle is different than the secondary angle — that progressively enter then exit the material, minimizing pressure at the center and reducing the risk of delamination and burst-out in the exit hole. Combining these with large open flutes helps to shed debris when drilling stacked laminates.

Double margin drills possess a secondary margin — ground behind the primary margin — that reams the hole during the process, thereby eliminating the need for an additional reaming operation.

Trepanning drill points, which cut on outer edges, thereby eliminating pressure at the center, perform well for composite parts with low thickness or low resin content, while straight-flute, multifacet drills help to compensate for poorly supported or fixtured parts (but see “Shop practice impacts drilling success,” below).

“We’ve also simply explored usability improvements — small tweaks to cutting data, tool geometries and tool materials — that have resulted in a productivity surge overnight,” Diamantis adds, emphasizing that “tiny changes in the tool design can make a big difference.”

This selection of custom tools combines coatings and geometries that help overcome the increasing difficulty in machining composites as the materials get harder and the structures more tailored. Source: Cajero Ltd.

Exploiting new materials

As good as they are, carbide drill tools are no longer adequate for time- and cost-sensitive machining operations. “It is the old standby, because it has better edge sharpness,” says Merson. “However, it’s not the best for tool life.”

For that, there is diamond. Natural diamond is the hardest substance known, but polycrystalline diamond (PCD), a synthetic material, has gained popularity over the past few years because it offers 10 to 20 times the tool life of uncoated carbide.

There are two basic types of PCD used in cutting tools. A PCD tip or insert may be brazed (up to 1200°F/649°C) into a groove cut into a carbide blank or tool body. Alternatively, diamond powder and binder may be poured into a carbide tool groove and sintered in place. Both provide hard cutting edges but are expensive, at six to 10 times the price of regular carbide tools. “PCD is less flexible than carbide with regard to tool shape and geometry, but you can resharpen and replace the PCD, effectively lengthening tool life,” comments Harding. “However, PCD is inherently brittle and requires care in handling. If dropped, the tool’s PCD cutting edge can chip, which results in rapid deterioration.”

PCD does have some flexibility, at least in the form of tips and inserts. There are different grades that can be optimized for specific applications, and the angle of the inserts may be adjusted to improve cutting forces and debris removal. However, Merson notes that because PCD is harder to grind than carbide, companies that produce tools by grinding PCD typically do not achieve the same tolerances.

Matching the tool to the material and application can boost tool life by 10 to 20 times and reduce cutting time by as much as 90%. Source: Cajero Ltd.

“Electron beam processing can be used to tighten up the tolerances, but adds more cost,” she explains. “This may be well worth it for achieving a much lower overall project cost, as cutting tools are typically only 3 to 5 percent of the total machining cost, with the rest comprised by consumables, time to cut, time for cutting tool change-out, etc.”

More recently, chemical vapor deposition (CVD) has begun to replace PCD in certain applications. Often referred to as diamond coating or diamond-coated carbide (DCC), this technology begins with a carbide blank that is pretreated to enable diamond to “grow” directly on its surface in thicknesses of 0.2 to 0.3 mils (6 to 8 µm). Harding comments, “Thus, you can still maintain the cutting edge, and the carbide base allows for material-specific edges and geometries. CVD offers the flexibility of carbide, the tool life of PCD and is more shop-friendly as well.”

Sandvik Coromant has found that PCD is superior for drilling and CVD is best for trimming. But Merson cautions, “This is in regards to tool life only, not counting cost. But people’s opinions will vary based on their background. If they come from drilling, they like PCD while if they come from trimming, they prefer CVD.”

“Using PCD or CVD drills, combined with certain geometry, can almost always extend tool life and sometimes decreases the tool change frequency dramatically,” Harding sums up. “Even if changing the cutting tool takes only five minutes, disrupting the operation costs money. PCD and CVD tools cost more initially, but operations are disrupted less.” He also points out that PCD tools can be resurfaced and resharpened to extend their useful life. “Thus, you lower the overall program cost and increase its productivity.”

A Lockheed Martin technician tests, via hand fastening, holes machined by an AMAMCO-customized composite drill tool. Source: AMAMCO

Diamantis, however, believes diamond coating is the way to go because its advantages come at less expense. A PCD tool is three to five times the cost of a competitive CVD tool. “In composites, all tools need to be coated,” he adds. “There are so many coatings being developed now to improve tool life. Even for stacked materials, there are coatings that will help the tools last longer and absorb the shock without chipping when the tool hits the metal.”

For example, CVD Diamond Corp. (London, Ontario, Canada), which focuses on cutting tools that use the firm’s pure diamond films, points to a recent carbon fiber composite milling application that required an end mill. Using a competitor’s tool, the customer could mill only 10 parts before tool failure. A switch to a CVD Diamond tool increased part throughput to between 30 and 40 before failure and reduced cutting tool costs by $500 per tool used. In aerospace, CVD Diamond says it has worked on a fighter jet application to develop a ball nose end mill to drill 270,000 holes in a carbon fiber composite structure. One tool drills 28,000 holes, beating a competitor’s best case of 10,000 holes using another diamond-coated tool.

LMT Onsrud LP (Waukegan, Ill.) notes specifically that using metal cutting tools to cut or drill composites can be costly in terms of tool wear and damage to workpieces. LMT Onsrud provides a wide variety of carbide, PCD-coated and nanocrystalline diamond-coated tools with an equal variety of tool geometries designed to minimize heat, prevent resin burn and provide clean fiber cuts. Such requirements are unique to composites, and subsequently the cost can be high: almost $800 for a specialized tool. Yet the coatings can result in 10 to 20 times longer tool life, and new geometries can reduce machining time by up to 90 percent. What’s required, then, is careful assessment to match the tool with the application to maximize throughput, tool life and value.

One-shot solutions for stacks

Although toolmakers disagree about which coatings and geometries are best, there is no argument that they are critical to efficient drilling of one-up assemblies. “CFRP requires high cutting speeds and feed rates,” Harding explains. “Titanium wants the opposite, being very sensitive to temperature and having a tendency to work-harden from the heat created during the machining process.”

This drill tool, with a small point, a gradually increasing diameter and a CVD diamond coating, has been specially designed for drilling CFRP. It’s maker. AMAMCO says CVD coatings have begun to replace PCD because the former attains the same useful life as the latter but offers the geometric flexibility of carbide at a lower cost. Source: AMAMCO

The solutions for each, therefore, couldn’t be more different. “The CFRP demands a long point and fast speed,” says Diamantis, “while the titanium demands a short, stubby point and slow speed, or it will burn up the drill.”

In the aerospace realm, even an all-CFRP part might not be all-CFRP. Harding notes, “Often, CFRP has additional layers of copper mesh for lightning strike protection on or near the surface, which can be challenging to machine tool. Copper is soft, while CFRP requires higher machining speeds and wears the cutting tool. This can smear the copper which then disables the cutting tool and greatly diminishes the ability to effectively machine the CFRP.” (Here, the old standby, carbide, will do. “We still recommend it for certain areas,” says Merson. “For example, with lightning strike protection, which needs very sharp edges or the whole part frays and falls apart.”)

No surprise, then, that a common solution for drilling stacked but unlike materials has been the use of multiple drill tools for each hole. “The three-stage drilling process is still commonly used today, requiring predrill, drill and reaming operations to achieve desired surface and dimensional quality,” says Merson.

This is a pet peeve for Diamantis, who contends that the composite manufacturer should deal with a machine tool provider who can design a “one-shot” drilling solution. “We supply a lot of different Boeing operations, and for all of them we supply one drill tool for one hole. We just don’t see the efficiency of using two and three separate drill tools and/or operations for each hole.” He continues, “Our expectation, as well as our customers’, is a tool that addresses all of the materials.” It may sound impossible, he admits, “but we are doing that on a routine basis.”

AMAMCO offers one-shot drilling solutions but prefers CVD over PCD. Diamantis contends, “I’ve seen so many shops resist changing their PCD tools, even though they require two operations. That is, until they try our CVD one-shot tool and see for themselves that it outlasts the two PCD tools they were previously using.”

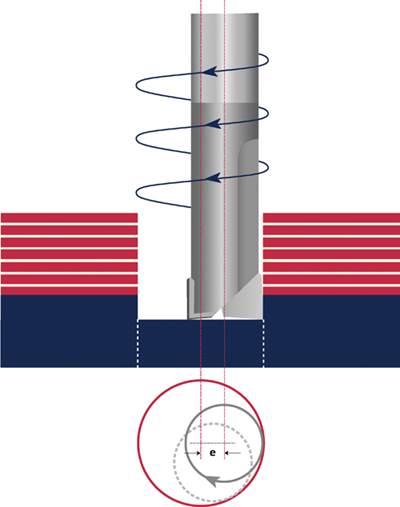

But Sandvik Coromant has developed solutions that avoid this, argues Merson. “One of our latest uses power feed machines and a helix flute drill based on a veined PCD point with a specific geometry optimized for titanium/CFRP/aluminum stack materials.”

The key is to control stacked laminate machining, layer by layer. “You do this by adjusting cutting parameters for each material,” Harding explains. One strategy, says Diamantis, is a drilling technique called micropecking. “What you want to avoid when drilling composite/titanium stacks are the long chips from the titanium scarring the inside hole of the composite as they exit.” The drill motor is designed to slow when it hits the titanium, then apply force, then retract, many times per second. This hammers the titanium chips, breaking them up as they are cut. The smaller debris is carried up and out of the hole in the drill’s fluting so it can’t scar the composite.

Optimizing today and tomorrow

Collaborating with machine tool manufacturers offers the potential for sizable reductions in cost, scrap rates and process flow time. “The latest cutting tools deliver exceptional productivity, slashing machining time and reducing overall production cost,” says Cajero’s Harding. “Such tool life advances and other productivity improvements … enable the manufacturer to do more without having to purchase additional machines or build a bigger plant.”

Further, toolmaker services today can extend to the testing and proofing of both tools and processes. Cajero, for example, helps companies remove uncertainty from new projects by prevalidating cutting tools and operations. “Customers send samples of material to be machined along with their specifications,” says Harding. “We then machine the material and send back a report on recommended tools and options as well as a videotape of the tested machining operations, which is worth more than a thousand words.”

Cajero also offers prevalidation trials in its own dedicated CNC-machining center. “When large scale cutting tool trials can cost OEMs upwards of $100,000,” Harding explains, “it is crucial to ensure that their key revenue streams are maintained by not diverting their capacity onto testing activities that disrupt production flows.”

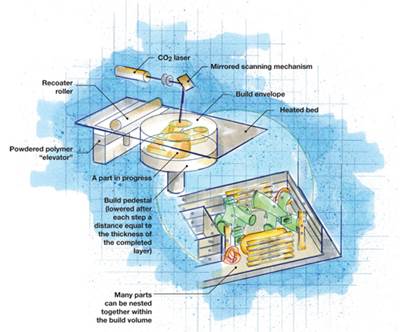

Merson notes that the “custom” trend could lead to fundamental changes in the way cutting tools are manufactured. For example, machine toolmakers are experimenting with 3-D printing, a popular form of additive manufacturing. She explains, “The tool is 3-D printed straight into carbide instead of grinding a blank down. Various universities are researching this now and getting good results, though it is difficult to do without some porosity in the tool structure.” All of the cutting tool manufacturers are interested, she says, but notes that “they are approaching it differently.”

The future? Harding sees automotive as the next frontier for automated composites machining — and a challenging one. “The auto industry is demanding more automation with composites and lower cost, while maintaining repeatability. Robotics here are more the norm, but the resins used are vastly different from aerospace. We have been single-source suppliers for several luxury and supercar marques, but these are low-volume manufacturers. What GM, Ford and Volkswagen want is much different. We’re having to optimize machining tool design for their higher volumes and more robotically automated operations.”

In the meantime, the goal for drill tool makers is to continue to reduce the cost of machining by applying their increasing knowledge and, as a result, improve their customers’ bottom lines.

Related Content

Mel Composites adds Rohacryl processing to customized core offerings

Addition of machining services for the Evonik structural foam brand expands Mel’s range of foam core delivery.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreLoop Technology robotic machining system works with harder materials

The RoboMach HA is a high-accuracy robotic machining system that can work with a range of materials, including cured composites.

Read MoreFrom the CW Archives: Drilling is not for the faint of heart

This edition of From the CW Archives revisits CW’s first plant tour — a visit to the F-35 FAL in Fort Worth, Texas — and a story by Ginger Gardiner a few years later. Both offer lessons on how to perform stacked drilling through composite and metallic materials.

Read MoreRead Next

The rise of rapid manufacturing

An outgrowth of rapid prototyping, tool-free additive fabrication technologies have the potential to form small, limited-run composite parts directly from CAD data.

Read MoreOrbital Drilling enables “one-up assembly”

Orbital Drilling, a technology patented by Novator AB (Spånga, Sweden) offers multiple hole sizes from a single drill tool.

Read More

.jpeg;maxWidth=720)

.jpeg;maxWidth=300;quality=70)