JEC COMPOSITES 2007 Highlights

Advanced composites make notable marks not only in traditional aerospace apps, but in automotive, sport and infrastructure arenas as well.

JEC COMPOSITES 2007 highlights Advanced composites make notable marks not only in traditional aerospace apps, but in automotive, sport and infrastructure arenas as well.

The annual JEC COMPOSITES Show (April 3-5, Paris France) brought together more than 1,000 exhibitors and thousands of composites industry professionals for three days of networking, learning and interaction. The HPC staff was on hand and found the following while walking the aisles at Paris Expo exhibit hall.

High-performance motorsports were the watchword at several stands. Huntsman Advanced Materials (The Woodlands, Texas) showed a Pescarolo LeMans-series race car, designed and built by legendary racer Henri Pescarolo — a multiple LeMans winner and holder of the record for the fastest speed on the famed Mulsanne Straight. Pescarolo used prepregs made with Huntsman epoxy as well as the company’s Araldite epoxy adhesives to construct the all-composite sports car. VISTAGY Inc.’s (Waltham, Mass.) stand featured a Formula 1 car from the ING Renault team. ING’s chief designer Bob Bell, was available to discuss how VISTAGY’s FiberSIM software accelerated composite component design time by 17 percent, reduced part count, increased production consistency and reduced overall layup time by more than 60 percent. Gurit (Wattwil, Switzerland) demonstrated a hood for the Aston Martin DB9 sports coupe that made use of Gurit’s trademarked SPRINT resin film infusion system. At the Hexcel (Dublin, Calif.) stand, the carbon fiber/epoxy engine frame for the Lamborghini Murciélago roadster was on display, fabricated by automotive fabrication specialist ATR Group (Colonella, Italy).

Notable research and development news included RocTool’s (Le Bourget du Lac, France) announcement of a breakthrough for much-improved resin transfer molding (RTM) cycle times using the company’s CAGE inductive mold heating technology. At its stand, the company displayed a reduced-scale car floor panel RTM’d with the CAGE technology in a two-minute cycle. RocTool hopes this cycle time will help composites continue their migration into automotive manufacturing.

Among the firms announcing working partnerships or acquisitions was Advanced Composites Group Ltd. (ACG, Heanor, Derbyshire, U.K.), which announced that it will collaborate with GrafTech International Ltd. (Parma, Ohio) to produce tooling, using GrafTech’s carbon foam as the tool body and ACG prepregs on the tool face. Business changes revealed at the show included the purchase of TCR Composites (Ogden, Utah) by Fabric Development Inc. (Quakertown, Pa.).

Literally the biggest thing at the show was a carbon fiber bridge manufactured by FiberCore Europe (Rotterdam, The Netherlands) and destined in early May for the Dutch town of Dronton. This bridge — 24.5m long by 5m wide (80.4 ft by 16.4 ft) and weighing 12 metric tonnes (26,455 lb) — was walked on, poked and prodded by just about everyone at the show. Designer Jan Peeters, who handles R&D for FiberCore, said the sandwich structure features a large, corrugated honeycomb core layed up in a sinusoidal pattern between composite skins that consumed 3 metric tonnes (6,614 lb) of commercial grade Panex 35 carbon fiber from Zoltek Inc. (St. Louis, Mo.). Fiber sizing and vinyl ester resin for the bridge project were provided by DSM Composite Resins AG (Schaffhausen, Switzerland). Peeters emphasized the adaptable, proprietary tooling system that FiberCore used to accommodate a variety of lengths, widths and other dimensions. Given that the cost of tooling for such large composite structures often makes them prohibitively expensive, Peeters and FiberCore hope and expect that serial production is within reach. Peeters says the cost of the carbon fiber bridge is competitive with concrete and weighs nine times less than concrete. Peeters also says the bridge was load tested with 75 metric tonnes (nearly 164,400 lb) of weight and showed deflection of only 64 mm (2.52 inches).

Smaller but impressive nonetheless was the cargo bay door for Airbus Industrie’s (Toulouse, France) A400M military airlifter. This all-composite structure, measuring 6m by 4m (about 20 ft by 13 ft), is the featured component in this issue’s “Inside Manufacturing,” p. 60.

Nanoledge (Sophia Antipolis, France) brought to JEC a Look 595 carbon fiber bicycle frame made with Nanoledge’s carbon nanotubes. The company report’s that it had compiled a wealth of new data in its research of components with nanotubes vs. those without, including improvements in crack growth resistance (30 percent), compression resistance (22 percent), impact resistance (50 percent) and flexural strength (50 percent).

Owens Corning (OC, Toledo, Ohio) introduced PerforMax HR 562 and PerforMax SP 798 chopped glass strand (maximum 3-mm/0.12-inch length). HR 562 is designed for use with polyphenylene sulfide (PPS) in plumbing and hot water contact applications. SP 798 is designed for liquid crystal polymer (LCP) and PPS in high-heat (up to 400°C/752°F) computer and electronics applications. During JEC’s Construction Forum, OC highlighted its collaboration with Petrofisa do Brasil Ltda. (Mandirituba, Brazil) to produce filament-wound utility poles using OC’s Type 30 SE1200 single-end roving with a polyester resin. Destined for the South American market, the poles are said to be two to four times lighter than wood poles and are expected to last up to 45 years — compared to 15 years for wood poles.

Among the most interesting processes highlighted at the show was one that allows for the insertion of metal components in a carbon fiber part, developed by Carbone Forgè (Lentilly, France). The company’s molding process uses proprietary tooling, employs a compression press and permits strategic fiber orientation in the charge. Among the parts in the Carbone Forgè stand was a 10-inch/254-mm diameter aircraft wheel (see photo, at left), with comolded steel rims and other metallic hardware. The wheel was fabricated by EADS Composites Atlantic (Lunenburg, Nova Scotia, Canada), which licenses the Carbone Forgè process. The wheel features long-fiber carbon reinforcement provided by Toray Industries (Tokyo, Japan) with a thermoplastic PPS resin.

A stone’s throw from the JEC show, and running concurrently at Hotel Mercure, the SAMPE Europe conference (April 2-4) featured papers covering composites technology and its application in aerospace, building and construction, testing, textiles, nanomaterials, modeling and — in keeping with the conference theme — energy systems (see “Learn More”). SAMPE reports that 324 people attended the conference, hailing from 27 countries spread over four continents.

Related Content

Scott Bader, Oxeco partner for high-performance bonding solution

Joint technology breaks barriers to bonding lightweight flexible solar panels to roofing structures made from aluminum, coated steel and composites.

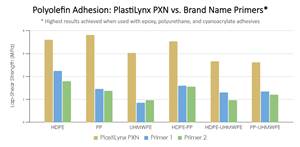

Read MoreXlynX’s PlastiLynx PXN crosslinking primer enhances polymer adhesion

PFAS-free diazirine primer makes surfaces receptive to all manner of adhesives, including epoxies and polyurethanes, outperforming alternative options by 150-350%.

Read MoreXlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

Read MoreBiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More