Carbon fiber guide dog handle improves coordination and comfort

Refitech was a finalist in the JEC 2019 Innovation Awards for a carbon-fiber guide dog handle that it produced for the Royal Dutch Guide Dog Foundation (KNGF).

Share

One of the finalists for the JEC 2019 Innovation Awards was Refitech (Waalwijk, the Netherlands), who specializes in engineering and producing industrial composite components for a variety of markets including industrial automation, UAV systems, medical equipment and marine systems. The company’s entry in the Innovation Awards’ Sports & Heathcare category was for a carbon-fiber guide dog handle that it produced for the Royal Dutch Guide Dog Foundation (KNGF).

According to Bas Nijpels, sales engineer for Refitech, the lightweight system replaces a guide dog handle constructed of metal tubing, offering a solution that weighs more than 50% less than the previous version. The solution offers more comfort to the guide dog as well as the owner. The lightweight handle stays in position above the dog’s back and easy to find for the owner. In addition, the new guide dog harness offers improved performance due to an improved fit of the harness. This allows for improved communication and coordination between the dog and the owner. The owner can better feel the movement of the dog and the dog can better sense signals from the owner.

The harness conceptual design was developed by NPK Design (Leiden, The Netherlands) and Refitech undertook the production aspects of the bracket, as well as prototyping and material sourcing. The company produced the handle using unidirectional carbon fiber prepreg and a closed molding process.

“As the KNGF is a non-profit organization that depends on donations for its work, we knew upfront that costs would have to be kept at a minimum,” says Nijpels. “After optimizing the design for easier mold removal and the use of prepregs, we now supply the new bracket at a very favorable rate, also thanks to our production facilities in China.”

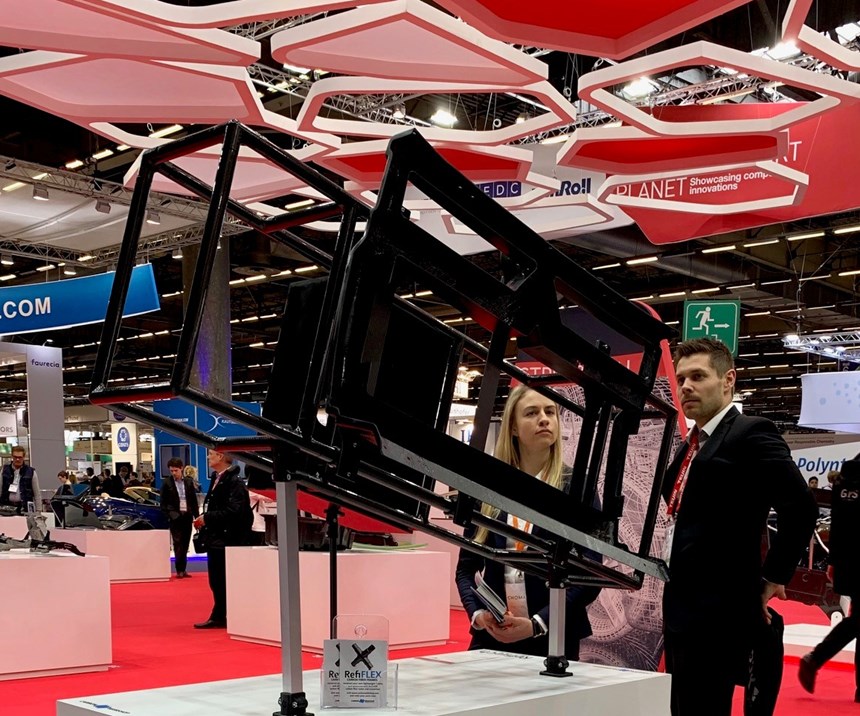

Refitech also introduced its new Refiflex range of carbon fiber components for lightweight construction at JEC World 2019. The system consists of standardized tubes and connectors that offer engineers a lightweight construction method for frames and trusses for a range of applications. Two versions of the construction systems are available, one consisting of 30mm round tubes and matching connectors and one based on 25x25mm square tubes. Possible applications range from machine building to UAVs to industrial automation.

Related Content

-

ExoTechnologies completes testing on recyclable motorcycle helmet

Helmet fabricated from Danu composites demonstrates improved weight reduction, impact resistance and complete recyclability compared to carbon fiber alternatives.

-

Lighter, stronger, faster bionic hand aided by composites design

Psyonic’s touch-sensing prosthetic hand leverages bionic technology, 3D printing and a carbon fiber composite exterior for light weight, high strength and high-tech functionality.

-

Running shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.