Share

Read Next

It all started with the Ansari XPrize. Wealthy space enthusiasts Anousheh and Amir Ansari offered $10 million to the first private enterprise, worldwide, “to build a reliable, reusable, privately financed, manned spaceship capable of carrying three people to 100 km [62 miles] above the Earth’s surface twice within two weeks,” says the Ansari XPrize website.

The award, given in 2004, went to Mojave Aerospace Ventures (MAV, Mojave, CA, US), owned and funded by Microsoft co-founder Paul Allen for spaceship technology engineered by Burt Rutan and his Scaled Composites team at the Mojave Spaceport. The spaceship that reached the goal was an all-carbon fiber composite structure named SpaceShipOne. In one of the many departures from the ordinary in this venture, the spaceship did not launch from Earth’s surface, but was delivered part of the way to its destination by the (also) carbon fiber composite WhiteKnight. Dubbed the mothership, WhiteKnight was designed to replace the first stage of a traditional rocket used to launch a craft from Earth’s surface. When WhiteKnight reached its target altitude, SpaceShipOne was released from its mothership and a dedicated rocket on SpaceShipOne provided the second-stage boost, driving the spaceship up to its suborbital goal.

Suborbital goal for tourists

Rutan and Richard Branson of Virgin Group (London, UK) had an ambitious new idea for the WhiteKnight and its SpaceShip: tourism. Together they set up Virgin Galactic space flight company in Las Cruces, NM, US, and in 2005 announced plans to form The Spaceship Co. (TSC) in Mojave to produce the spacecraft that would lift passengers to suborbital space (~50 miles/80 km) for a heavenly view of Earth and a few minutes of weightlessness. Because the sight of Earth from space has been described as giving the viewer a “feeling of unity,” TSC decided to name its next spaceship model, SpaceShipTwo (SS2), after that concept: Unity.

Rolled out in February 2016, SS2 was officially named VSS Unity by the late Professor Stephen Hawking — famed scientist and Lucasian Professor of Mathematics at Cambridge University (Cambridge, UK) — who spoke at the ceremony: “A man with the vision and persistence to open up space flight for ordinary, Earth-bound citizens, Richard Branson made it his mission to make space flight a reality for those intrepid enough to venture beyond the boundaries of the Earth’s atmosphere. … I would be very proud to fly on this spaceship. Space exploration has already been a great unifier — we seem able to cooperate between nations in space in a way we can only envy on Earth. We are entering a new space age and I hope this will help to create a new unity.”

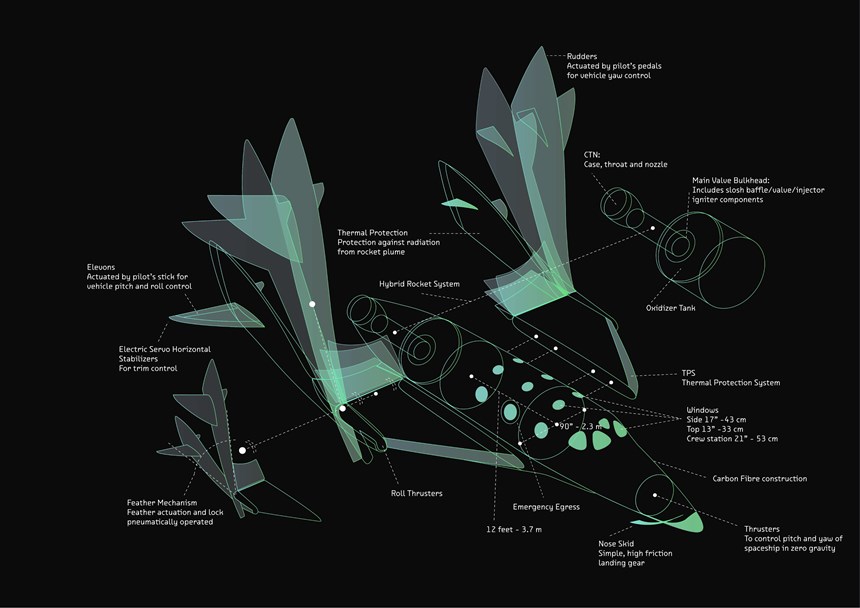

As of July 2018, about 600 people have signed up and paid up to $250,000 each for that opportunity. Faithful to the initial concept, the current WhiteKnightTwo (WK2, named Eve) will deliver SS2/Unity and its passengers to an altitude of about 9 miles/15 km (Fig. 1). (The current WK2 and SS2 are named Eve and Unity, respectively; future ships will be named when they are rolled out. See the Names table) At the apogee, WK2 pilots will release SS2 and SS2’s pilots will ignite its hybrid rocket to thrust it and its passengers toward an unequaled tourist experience: A minute of intense thrust at Mach 3, then weightlessness, while watching Earth as it turns in their view. SS2 will then return to Earth, offering the experience of the return of gravity (g-force) and high heat on re-entry to the Earth’s atmosphere. All aboard will be protected from high temperatures as the spaceship decelerates through the atmosphere by proven thermal protection, originally developed by NASA for the Space Shuttle (Fig. 4 and Step 9).

Composites enable space tourism

“We probably couldn’t do this mission if we were not building these vehicles out of all carbon fiber construction,” TSC President Enrico Palermo states. “We are leveraging the true benefit of composites in these spacecraft, designing and building structures that are efficient and as a result lighter and therefore need less propulsion to soar into space.”

TSC builds on a deep foundation of composites knowledge and experience from Rutan, who began conceiving, designing and building composite airplanes in 1974, and founded Scaled Composites in 1982. Acquired by Northrop Grumman in 2007, Scaled has been and is renowned for experimental composite aircraft designs and construction, plus the success of its spaceship approach for the Ansari XPrize.

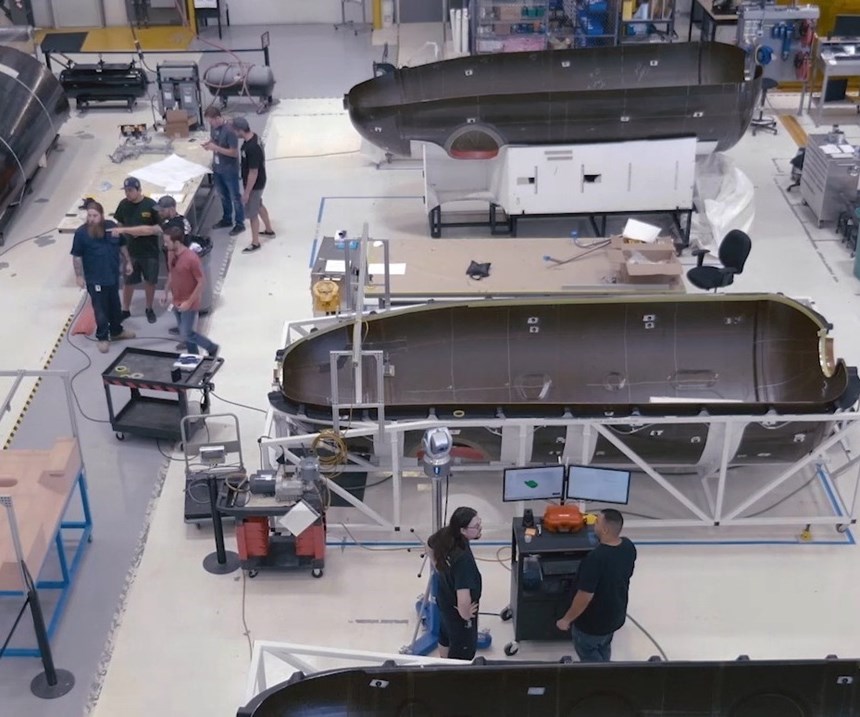

With its access to this legacy, TSC is finding new techniques to successfully apply Rutan’s basic manufacturing processes of hand layup, vacuum bag and out-of-autoclave (OOA) cure, while advancing its own methods for its specific spacecraft challenges. Alec Subero, TSC’s chief engineer for the next two spaceship models, SS2-003 and SS2-004, interprets TSC’s own paradigm: “What’s unique, what allows us to actually meet our space tourism goal, is that we use the processes in a different way. We have fine-tuned procedures based on the legacy from our predecessor technology that allow us to build the spaceships by less costly and faster methods, that allow us to be more nimble in our approach to changes, compared to a larger company that might be slower and more reluctant to react. For example, our combination of adhesives and OOA prepreg processing opens up flexibility in cure cycles, allowing us to make design changes quickly while minimizing disruption in the assembly flow of the spaceship.

“We also employ very talented technicians who are very skillful with their hands,” he adds. Laser projection and automated ply cutting technologies are used to reduce the manual labor content and to maintain accuracy of the hand-build approach and “we are continually exploring other automated approaches that might be compatible with our organization,” Subero says.

Standard assembly procedures are followed, and the various structural sections of both vehicles are bonded together using an epoxy-based paste adhesive plus metal fasteners in some areas.

Primary structures

Nearly all primary airframe structures for both WK2 and SS2 are sandwich structures. TSC builds the sandwich inner and outer skins using MTM45-1 plain weave fabric prepreg made by Solvay Composite Materials in Tulsa, OK, US (headquarters in Alpharetta, Georgia). The prepreg fiber is Tenax HTS40 standard modulus carbon fiber, now manufactured by Teijin at its Mishima factory in Shizuoka, Japan (Teijin headquarters is in Tokyo, Japan). One of the key benefits of the MTM45-1 system is OOA processing.

The sandwich core is aramid Nomex aerospace grade honeycomb, AHN4120, made by Advanced Honeycomb Technologies (San Marcos, CA, US); it is said to exhibit high strength and toughness in a small-cell, low-density, non-metallic honeycomb, according to Advanced Honeycomb. It is also known for providing corrosion- and fire-resistance as well as good thermal insulation properties. From a manufacturing standpoint, it is also considered well-suited for adhesive bonding.

The 42.6m/140-ft-long wing span on WK2 is built with two single-piece carbon fiber composite spars that run nearly the full length of the wing. Built in the manner of a conventional wing, the spars and ribs are installed into the sandwich structure for the lower wing. After various lines and control systems are also installed, the lower wing is closed off with the sandwich structure for the upper wing. A similar approach is used for building the boom tails for WK2 and SS2, “which are basically a pair of vertical wings,” Subero says.

Two fuselages for strength and balance

WK2 presents the highly unusual design configuration of two fuselages, right and left of the center wing. This gives the aircraft both strength and balance for its job. The strength for a lifting capacity of 15 tons, which includes the SS2 locked between them, and stability when the weight of SS2 drops away from WK2 by natural gravity upon release. Subero notes that the twin boom tail design allows for the SS2 spaceship to be carried safely between the fuselages during flight and away from the structure when it is released by a pneumatically activated mechanism. These fuselages are identical in structure, each 23.8m/78 ft long, leading with the nose, which houses the landing gear, followed by a cabin, and then a boom section that extends to a 7.9m/26-ft-high horizontal tail. The right fuselage (facing forward) is a pressurized cabin fitted for two pilots, with an optional seat for a flight test engineer. The left cabin is unpressurized and contains ballast to keep the vehicle’s center of gravity along the centerline.

SS2 has the normal single fuselage. It comprises a nose housing the landing gear, which is connected to a pressurized cabin and crew station of the same size, design and construction as WK2’s pressurized cabin but is fitted for up to six passengers, in addition to the two-person crew. “The design commonality has multiple benefits,” Palermo points out, “first in allowing for common composite tooling, but more importantly allowing the WK2 to serve as a pilot trainer for SS2 with a similar cockpit layout.”

Feathered re-entry

The second half of the SS2 includes what TSC calls the feather, which is part of the wing structure. After SS2 has released from WK2, and after its rocket has burned out, SS2 achieves the apex of its flight. At this point the pilot pneumatically actuates the feather to its folded-up position, from 0° to 90°‚ (Figs. 4 and 5), to increase drag and reduce speed for re-entry into Earth’s atmosphere. If the spaceship were re-entering Earth’s atmosphere from low-Earth orbit or higher, a different technology would be required to withstand greater heat and g-forces associated with re-entry from those altitudes. At SS2’s re-entry point from the edge of space, though, the feather is a sufficient and inventive way to safely slow the descent. (Following a deadly accident due to premature feather deployment during a test in 2014, TSC redesigned the system to prevent a repeat of this failure.)

Similar to the effect of a badminton shuttlecock, the right-angle position of the feather induces high drag forces from oncoming air resistance. Further, it holds the SS2 at the correct aspect, descending belly down, to safely re-enter Earth’s atmosphere. The ship is not powered during descent, but glides toward its destination. As it approaches the ground, the pilot again extends the feather to its normal wing position for safe landing.

The wing and feather are both carbon fiber composite sandwich structures, built from the same materials and process as the WK2 wing and the fuselage sections. The feather consists of a set of small wings called the feather flaps that are attached to the wing at its aft spar by four metal clevis-and-lug fittings that allow the flaps to hinge up and down (Step 6 and Figures).

Rocket technology

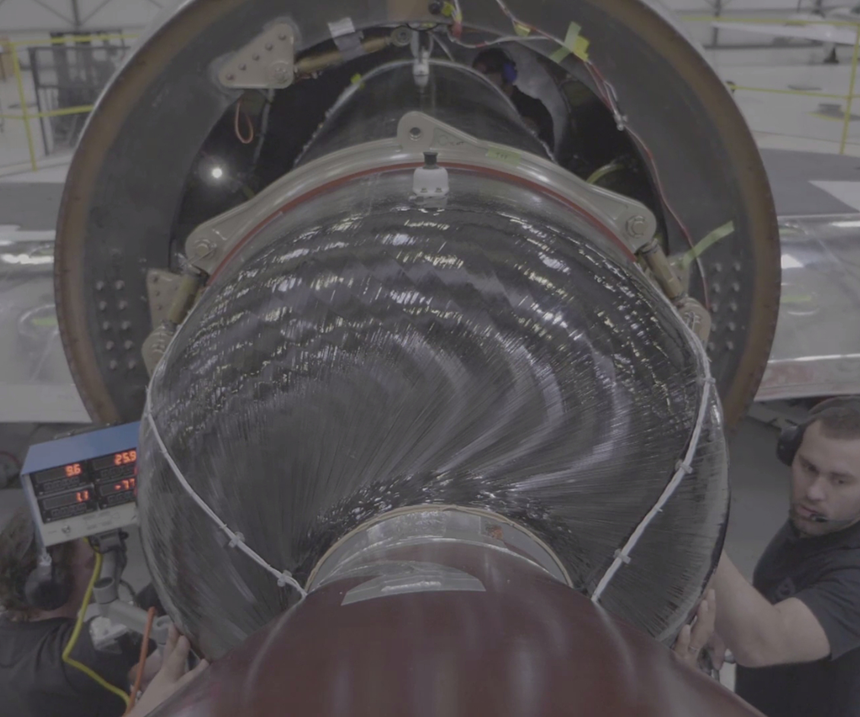

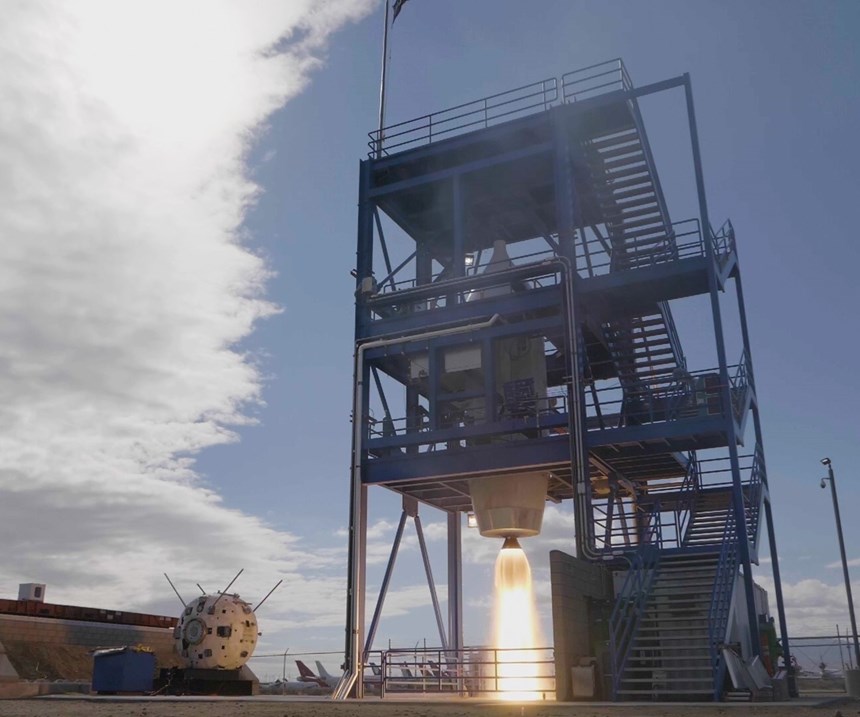

Extending to the rear of the SS2 wing and feather assembly, the aft fuselage houses the rocket and the main oxidizer tank. The rocket propellant is a hybrid of solid hydroxyl-terminated polybutadiene (HTPB) rubber-based fuel ignited by a carefully controlled flow of liquid nitrous oxide. “Unlike a traditional solid motor fuel, our fuel is stable and does not require special handling procedures to prevent ignition,” Palermo explains. A valve in the nozzle assembly connects the HTPB in the rocket motor case with the main oxidizer tank. The throat nozzle assembly assembles the nozzle together with the chamber where the combustion reaction takes place. “It’s a very robust architecture having a very limited failure mode, which made rating this rocket motor for transporting people a lot easier,” Palermo says. Following TSC’s extensive ground test qualification program, the rocket motor is now qualified and human-rated for service.

The case is filament wound carbon fiber composite, but no details about the materials or process are available due to ITAR (International Traffic in Arms Regulations) restrictions. However, says Palermo, “Like the spaceship, its construction leverages the best properties of composite structures.”

[Author’s note: Unverified reports from within the composites industry suggest that motor cases for solid propellant are generally filament wound — sometimes directly over the solid propellant — probably using a mid-modulus carbon fiber and high-temperature resin. Structures for liquid fuel systems, such as liquid oxygen, tend to use automated fiber placement (AFP) systems using prepreg tape or fabric.]

WK2 engine cowlings are also composite, as are the inlet duct and exhaust nozzle, made with an unidentified high-temperature composite material. Palermo identifies WK2’s engines as “four highly efficient high-bypass turbofan jet engines made by Pratt & Whitney, Canada” part of the United Technologies Co. (East Hartford, CT, US) — “a great supplier to our program for many years,” Palermo adds.

Onward, upward and return

On July 28, 2018, WK2 successfully carried and launched SS2 from the Mojave airport up to a height of 8.8 miles, where its rocket shot another 23.5 miles straight up to a record 32.3 miles above Earth — the nearest SS2 has been to its ultimate goal of a 50 miles. Several more test flights are planned before the space pair enters commercial service.

Commercial flights ultimately will take off from Virgin Galactic’s Spaceport America facility near Las Cruces. Additionally, Virgin Galactic and TSC have signed a Memorandum of Understanding with Italian aerospace companies for construction of a spaceport in Grottaglie, Italy, to bring commercial spaceflights to Italy for science and tourism.

“Tourism is certainly our key market,” Palermo states, “but we are also pursuing suborbital science. SS2 is an excellent platform for microgravity research.” In the near future, Virgin Galactic plans to fly suborbital research payloads for NASA as part of its Flight Opportunities Program, which strategically invests in the growth of the commercial spaceflight market by providing flight opportunities on suborbital platforms and small spacecraft.

Spaceships SS2-003 and SS2-004 are now in fabrication and assembly at TSC Mojave, following SS2 and exploiting lessons learned in its design and manufacture.

Looking to the future, Palermo emphasizes TSC’s need for engineers in all disciplines — “design engineers, stress analysts, composites specialists, and more” — for its fully integrated, design-through-manufacturing-and-testing production cycle. “New engineers go through the same composites training that our new technicians take, so that they have similar exposure as the technicians and they understand the processes they are going to be designing for,” he says.

TSC is working toward establishing a high-rate production plant for the rocket motors, “because we have one spaceship and soon will have two more,” Palermo explains. “So when we have three spaceships in service we’ll need to produce these rocket motors at a relatively high rate.”

The rocket motor case and main oxidizer tank are essentially the fuel cartridges for TSC’s mission to space and are the only part of the SS2 that is not reused every flight.

Both WK2 and SS2 are fully reusable, Palermo emphasizes: “Reusability is at the heart of dramatically changing the economics of access to space to enable new markets to develop and enterprises to thrive. WK2, as the workhorse of our spaceflight system, is fully reusable and can release multiple SS2s per week.”

Related Content

Film adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreIPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MoreHeat-activated foaming core rapidly achieves net-shape 3D parts

CAMX 2024: L&L Products exhibits its InsituCore foaming core structural technology, which can be used to create foam core composites minus machining or presses, as well as the Phaster A K-700, a rapid-cure adhesive.

Read MoreScott Bader, Oxeco partner for high-performance bonding solution

Joint technology breaks barriers to bonding lightweight flexible solar panels to roofing structures made from aluminum, coated steel and composites.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More