Living in space, surrounded by composites?

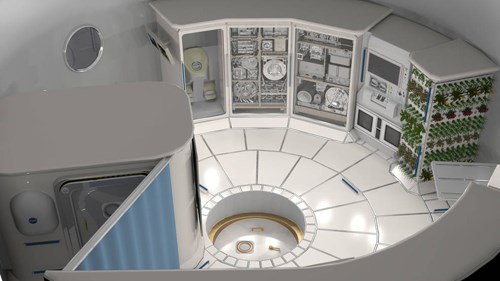

As humans travel further into space, the structures in which they live will become extremely important. NASA is working with six companies on development of deep space habitat designs that could represent a new end market for composites.

As humans venture deeper into space, habitation structures will be an important part of their living environment. NASA is working with six companies on development of deep space habitat designs.

It's not hard to imagine, when humans venture into deep space, that composites will be along for the ride in a variety of structures, ranging from space craft to the very structures in which humans will live. Along those lines, NASA has selected six U.S. companies to help advance the journey to Mars by developing ground prototypes and concepts for deep space habitats.

Through the public-private partnerships enabled by the Next Space Technologies for Exploration Partnerships-2 (NextSTEP-2) Broad Agency Announcement, NASA and industry partners will expand commercial development of space in low-Earth orbit while also improving deep space exploration capabilities to support more extensive human spaceflight missions.

The selected companies are:

- Bigelow Aerospace (Las Vegas, Nevada)

- Boeing (Pasadena, Texas)

- Lockheed Martin (Denver, Colorado)

- Orbital ATK (Dulles, Virginia)

- Sierra Nevada Corp.'s Space Systems (Louisville, Colorado)

- NanoRacks (Webster, Texas)

“NASA is on an ambitious expansion of human spaceflight, including the Journey to Mars, and we’re utilizing the innovation, skill and knowledge of both the government and private sectors,” says Jason Crusan, director of NASA’s Advanced Exploration Systems. “The next human exploration capabilities needed beyond the Space Launch System (SLS) rocket and Orion capsule are deep space, long-duration habitation and in-space propulsion. We are now adding focus and specifics on the deep space habitats where humans will live and work independently for months or years at a time, without cargo supply deliveries from Earth.”

The six partners will have up to approximately 24 months to develop ground prototypes and/or conduct concept studies for deep space habitats. The contract award amounts depend on contract negotiations, and NASA has estimated the combined total of all the awards, covering work in 2016 and 2017, will be approximately $65 million, with additional efforts and funding continuing into 2018. Selected partners are required to contribute at least 30% of the cost of the overall proposed effort.

The ground prototypes will be used for three primary purposes: Supporting integrated systems testing, human factors and operations testing, and to help define overall system functionality. These are important activities as they help define the design standards, common interfaces and requirements while reducing risks for the final flight systems that will come after this phase.

NASA made the first NextSTEP selections in 2015, which include deep space habitation concept studies that also advance low-Earth orbit commercial capabilities. Four companies were selected under that solicitation: Bigelow Aerospace LLC, Boeing, Lockheed Martin and Orbital ATK.

This round of NextSTEP selections are part of a phased approach that will catalyze commercial investment in low-Earth orbit and lead to an operational deep space habitation capability for missions in the area of space near the moon, which will serve as the proving ground for Mars during the 2020s. These missions will demonstrate human, robotic and spacecraft operations in a true deep space environment that’s still relatively close to Earth and validate technologies for the longer journey to Mars.

Video: This lunar habitat is made of glass-fiber-filled ABS and offers three important lessons for printing large parts. Watch here.

Related Content

Pusan National University researchers introduce method to enhance thermally conductive composites

The proposed method has the potential to control the orientation of composite fillers without surface modification, improving thermal management.

Read MoreRice University turns asphaltene into graphene for composites

University scientists use novel flash Joule heating process to convert crude oil byproduct into graphene, to then be mixed with composites for thermal, anti-corrosion and 3D-printing applications.

Read MoreTRB Lightweight Structures partners with University of Bristol to broaden PFA offerings

Knowledge Transfer Partnership project aims to develop novel and improved PFA resin formulations for composite applications.

Read MoreWomen in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read More