Low-profile, high-performance manufacturer

Advanced Composite Products & Technology Inc. provides innovative and cost-efficient composite solutions to some of the most difficult and demanding real world applications.

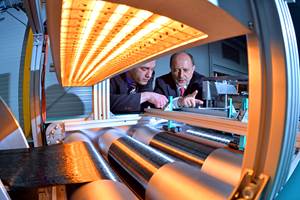

Whether you are aware of this company, or not, Advanced Composite Products & Technology Inc. (ACPT, Huntington Beach, CA, US) says it thrives on providing innovative and cost-efficient composite solutions to some of the most difficult and demanding real world applications. Founded in 1977 by Dr. James C. Leslie and his son, James Leslie II, the company is involved in design, development and manufacturing of advanced composite applications for research, commercial, government, and private institutions, with an emphasis on filament winding. The market sectors that ACPT serves include space, aviation, defense, motorsports, marine, converting, heavy industry and drilling.

ACPT is located within what might be called the Huntington Beach composites cluster, in close proximity to at least six other composites companies. Like its neighbors, ACPT offers a wide range of in-house capabilities. It has a number of 4-axis CNC filament winders, the largest having a length of 11.1m or 36.2 ft, electronically-controlled tensioners and numerous curing ovens. Lamination-related equipment includes a clean room, vacuum mixer, bladder and trapped molding equipment, and a finishing area and paint booth. Ovens and autoclaves are on premises, as are hydraulic presses for compression molding and press-forming. A fully-staffed machine shop allows for grinding, drilling, milling and all other required finishing operations. The company conforms to its quality assurance management system and has been audited according to the requirements of AS 9100.

Over its 41 years of operation, ACPT has, rather than focusing on one business area, designed, prototyped and manufactured an array of unique parts for a diverse customer base, from low rate to full production. A sampling of parts includes but is not limited to aircraft ducting, satellite components, launch tubes and ordnance components, cryogenic tanks, radomes, UAV components, lightweight industrial converting rollers, automotive and industrial driveshafts and high-demand critical military applications. “While we can’t share specifics about our projects, one example I can mention was an early program with the US Department of Energy to develop offshore composite drill pipe. Since the completion of this program we have developed and commercialized various composite applications for the oil & gas industry,” says Jim Leslie.

To complete those projects, ACPT, like other composite manufacturers, partners with composite material suppliers. One of these is Magnolia Advanced Materials (Atlanta, GA, US, http://magnolia-adv-mat.com ), a supplier of a diverse card of materials, from epoxy resins and adhesives to coating and conductive materials, liquid shims, potting and encapsulating compounds, sealants and syntactics, tooling and casting resins, and finally, custom or toll formulating for specific requirements. Magnolia was an important supplier for a recent confidential project involving design and manufacture of a carbon fiber vehicle driveshaft. Leslie adds that the company uses thermoset resins combined with carbon, glass and aramid fibers for its projects. ACPT suppliers also include Mitsubishi Chemical Carbon Fiber & Composites Inc. (Irvine, CA, US), Toray Composites (America) Inc. (Tacoma, WA, US), Teijin Carbon America, Inc. (Rockwood, TN, US) and Composites One (Arlington, IL, US).

ACPT tells CW that it constantly implements continuous improvement methods and process controls throughout its business, and that it is devoted to investing a lot of resources in these areas including unlimited training for all employees. Although ACPT Inc. operates in stealth mode, this California company is well-positioned for the future. Visit www.acpt.com for more information.

Related Content

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreToray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

Read MoreBelzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreChemnitz University of Technology receives €6 million to expand research into "green" carbon fiber

Carbon LabFactory and InnoCarbEnergy project conduct R&D across entire value chain from raw materials through processes to structures and systems on a pilot line with technology demonstrators.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More