Lower cost, less waste: Inline prepreg production

New technologies move direct (fabricator-based) prepregging closer to reality.

That composite laminates made from oriented plies of B-staged pre-impregnated unidirectional (UD) carbon fiber (prepregs) produce finished parts with the lowest mass, among the highest mechanical properties and low void content is undisputable. That they have been, historically, the most expensive, labor and scrap-intensive, is also well established. Efforts to mitigate the latter continue. Since the early 2000s, movement away from costly autoclave cure to a variety of out-of-autoclave (OOA) processes (Read more about OOA solutions in CW’s February 2015 "Out of Autoclave Supplement" located under "Editor's Picks," at top right) and the advent of nesting software, automated cutting equipment and laser projection systems has driven cycle times down from hours to 15-25 minutes and reduced scrap rates that ranged as high as 60%. Recently developed “snap-cure” epoxy resin systems maintain the out-life necessary to lay up large and/or complex parts, but offer, at trigger temperatures, cure cycles as short as 90 seconds. (Read more about snap-cure epoxies in "Automotive composites: Thermosets for the fast zone," under "Editor's Picks.") On the fiber side, prepreggers have moved to less expensive heavy tow (24-50K) in cost-sensitive industries, such as automotive, and fiber manufacturers are still in search of less costly fiber precursors (e.g., lignin) and less energy-intensive carbonization processes.

The next technology hurdle

What have not been addressed, to this point, are the inefficiencies inherent in the production of prepreg as an intermediate, discrete step in the supply chain. Two interesting approaches toward this end, both inline processes, were introduced at SPE’s Automotive Composites Conference & Exhibition 2015 in Detroit, MI, US. They turn composites fabricators into prepreggers in much the same way the direct long-fiber thermoplastic (D-LFT) process shifted the work of compounders to fabricators in the late 1990s/early 2000s. Both new technologies eliminate the previously necessary and expensive steps of freezing and storing prepreg prior to shipping it to the customer, who then must also store it and thaw it before using it in a molding process, the costs of which are borne by the processor and, presumably, the processor’s customer.

Towpreg for PCM

Closest to commercialization is an inline prepregging process developed jointly by Mitsubishi Rayon Co. Ltd. (Tokyo, Japan) and Mitsubishi Rayon Carbon Fiber & Composites Inc. (Irvine, CA, US). Otherwise conventional UD prepreg is produced in a hot-melt process by spreading dry fibers and pressing them between resin films to form consolidated sheets. Optionally, these can be slit into tapes, albeit at high cost. In the new process, Mitsubishi scientists reduce costs by directly coating single bundles of carbon tow, calibrating the width and then rewinding the product onto spools. An automated fiber placement (AFP) system — Mitsubishi calls it automated towpreg placement — is then used to lay up ply stacks, to eliminate the labor of hand layup. Stacks are subsequently preformed and molded via the company’s own prepreg compression molding (PCM) process (more on this shortly).

Towpreg is less costly than the slit tapes typically used on AFP machines (although it lacks the latter’s width tolerance); it is also easier to handle than wet (inline-impregnated) fiber systems, so the equipment runs faster with less scrap, again, reducing cost. Similar to Mitsubishi’s conventional PCM prepreg, the towpreg uses 24K or 50K carbon fiber tow that is impregnated with a press-ready, rapid- processing, solvent-free epoxy that reportedly cures in 3 minutes at 150°C. The towpregs are dry and rigid at room temperature for easy handling in the AFP machine, but upon heating, quickly tackify and stay viscous at molding temperatures to reduce flow and eliminate dry spots.

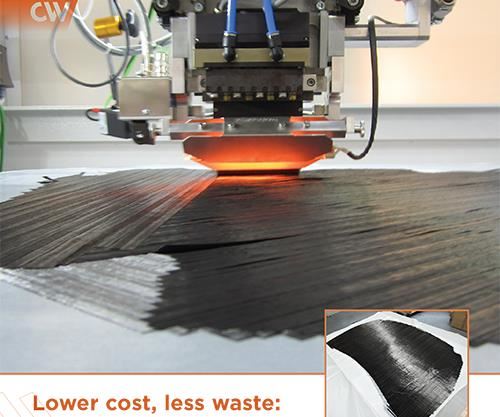

Although towpreg can run on any AFP machine, Mitsubishi uses a next-generation STAXX1500 AFP from BA Systems GmbH (Grenzach-Wyhlen, Germany), which is optimized for spooled towpregs instead of the usual slit tapes. Compared to earlier systems, it runs faster (minimum 30 kg/hr with 16 lanes), is less expensive (only two axes, not multiaxial), and has a smaller footprint, making it ideal for automotive applications.

“Replacing hand layup of prepreg with fully automated towpreg layup brings many advantages,” explains Max Thouin, technical sales manager, Composites Materials Div., Mitsubishi Rayon Carbon Fiber & Composites. “Once the layup path is designed and programmed into the machine, AFP provides rapid, repeatable, scalable and fully automated layup of a net-shape 2D laminate stack. This saves both cutting waste and kit production time, as well as ply layup time. Because towpreg is narrow and AFP machines can be programmed to leave holes in layup patterns [for cutouts], it’s easier to fill complex contours without extra material that otherwise gets trimmed away.” After layup, only a jagged edge is left around a part’s external contours, further reducing cost and waste, depending on design complexity. “Unlike conventional prepreg, which requires cold storage until ready for use, towpreg is stable at room temperature for several weeks, although longer storage does require refrigeration,” says Thouin. “This makes it easier to stop and start production steps, like when layup gets ahead of preforming and/or preforming gets ahead of molding or finishing.”

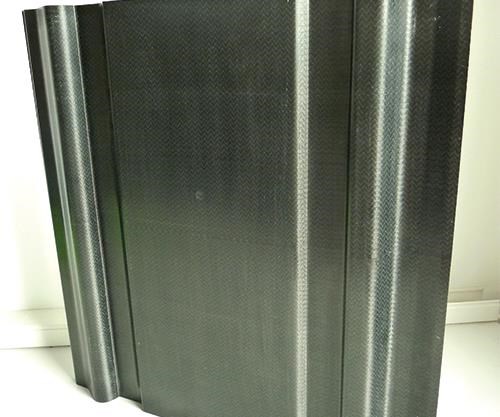

Notably, Mitsubishi’s PCM process uses a low-pressure, heated preforming station immediately adjacent to a conventional compression press. This setup reduces voids and improves surface finish, and could enable the many processors who already form sheet molding or bulk molding compound (SMC/BMC) or even D-LFT on compression presses to transition to higher margin carbon composites without a huge capital investment. A molder would only need to invest in an AFP (US$750,000-US$2 million) and a preforming station. Although PCM towpreg’s or prepreg’s 3.5- to 5.0-minute molding cycle (not counting preforming) can’t match SMC/BMC’s 2.0-3.5-minute cycles, it’s faster than most other OOA methods and far faster than vacuum-bag/autoclave processes. Because compression molding uses matched metal dies rather than single-sided tooling, and pressure is distributed evenly across all part surfaces, both A and B sides of parts exit the press with better surface finishes, reducing costly and time-intensive finishing. With a single tool set, Mitsubishi says the current PCM process could mold 84,000 parts/year with an even faster but still developmental 3-minute cure grade. When PCM is combined with less costly towpreg and faster, less wasteful AFP layup, 20-60% costs savings can accrue, largely by reducing waste and hand labor.

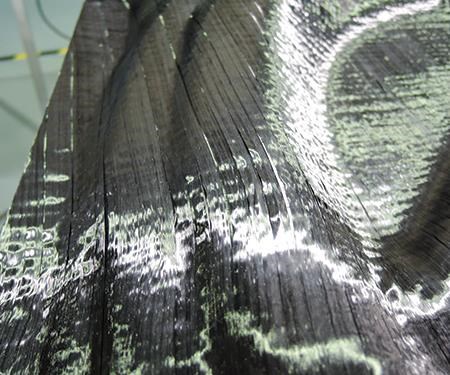

An unexpected benefit is that parts that can’t be satisfactorily molded in conventional prepreg can be molded with towpreg. This is because towpreg rovings aren’t locked together (across a single layer or between layers) in the same way as plies of preconsolidated prepregs or tapes. As soon as heat is applied, towpreg fiber bundles can move — stretch and shear — during preforming and molding. Because more movement is possible, towpreg is better able to fill complex tool contours and avoid bridging and resulting voids, overcoming a longstanding disadvantage of laminate composites. Recent work by Mitsubishi using a complex inner-panel liftgate tool showed that with PCM towpreg, researchers could fill challenging sections of the tool without the wrinkling or folding that occurred with PCM prepreg (see photos below).

Like any material/process combination, there are pros and cons to this development. The biggest disadvantage of towpreg PCM — fiber movement that results in gaps — is aesthetic (see photos and caption below. Aesthetic shortcomings can be addressed by painting parts or using them in non-visible applications, or by using a facesheet of conventional prepreg before building the rest of the structure with towpreg. The company says it is tweaking resin chemistry to further reduce flow as well as cure time. “Automated towpreg placement and PCM show great potential as a high-cycle CFRP molding process,” notes Koichi Akiyama, group leader, automotive development at Mitsubishi Rayon. “Part cost can be significantly reduced by limiting scrap and integrating automation.” (Read more about PCM in "Prepreg compression molding makes its commercial debut" under "Editor's Picks.")

Inline prepreg production

A different approach to reducing prepreg costs is the new InPreg (inline-prepreg) process developed by the Fraunhofer Institute for Chemical Technology (F-ICT, Pfinztal, Germany). F-ICT helped develop the original D-LFT process in the late 1990s, the tailored D-LFT process (with continuous rovings and fabrics) in the mid-2000s, and the direct-SMC (D-SMC) process about five years ago. Knowledge accumulated in these efforts, a unique resin system and machine automation have been brought to bear on the InPreg process to speed downstream prepreg cutting, stacking and molding steps.

Like Mitsubishi’s PCM approach, InPreg prepregs are designed to be formed in compression presses rather than more exotic equipment, thus opening up laminate composites to a broader range of processors. Unlike PCM, where preforming and molding are decoupled and completed in separate steps — which needn’t occur close together in time or space (prepreg can be preformed, then stored for days before being molded) — the InPreg preforming and molding steps are both accomplished in the compression tool. This eliminates not only the time needed to heat, preform and cool prepreg, but also the cost and space necessary for a preforming station.

Key to the Inpreg process is a four-part, B-stageable epoxy resin system used by industrial prepreggers (Araldite LY1556 resin, Aradur 1571 paste hardener, Accelerator 1573 paste accelerator, and Hardener XB3471 polyamine-based hardener from Huntsman Advanced Materials, Basel, Switzerland). “Due to the unique characteristics of this resin system, which uses a chemical B-staging step, it’s well suited for a faster inline process,” explains Klaus Ritter, marketing manager and head of Huntsman’s Composites Center of Excellence. “Traditional hot-melt systems also allow B-staging to be separated from final cure. However, their higher viscosity compared to chemical B-stage systems means much more exact impregnation equipment is needed to avoid triggering final cure during B-staging.”

F-ICT also uses lower cost 24-50K tow carbon fiber, which is formed into a UD, non-crimp fabric (NCF). This dry NCF reinforcement is said to impregnate faster and more easily than conventional UD spread-tow tapes. Because the process impregnates a single NCF layer at a time, voids are minimized and very precise fiber/resin ratios are achieved.

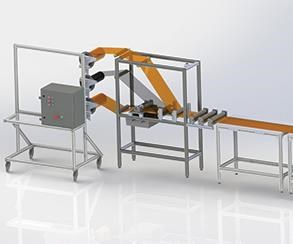

During development, the team built a small production line to prove the concept. To date, it has produced 1,000m of material, which has been used to mold and test small specimens cut from larger flat plaques, as well as some sizeable (550 mm by 500 mm by 35 mm) parts with 2.5D geometry.

The web-based line features four zones: impregnation, pre-cure, cooling and cutting. First, NCF reinforcement is pulled through the system under controlled tension over rollers and impregnated. Pre-cure (to reach B-stage) occurs in the second zone and takes 4 minutes at 90oC. Next, prepreg is cooled to room temperature for 4 minutes to stop pre-cure and increase resin viscosity for easier handling. In the final zone, newly made material is cut. Then it leaves the line and is laid up in the compression tool, according to the ply schedule, and formed. Molding/full cure is achieved in 10 minutes in the press at impregnated. Pre-cure (to reach B-stage) occurs in the second zone and takes 4 minutes at 150oC and 7.5-8 bar.

Because the process isn’t overly complex and the line isn’t overly long, preimpregnation/pre-cure and cutting/stacking steps can be done in parallel, with both processes feeding the same press. InPreg prepreg remains stable for several days without refrigeration, so molders can build inventory to feed slower forming steps without needing to stop and freeze, then thaw, material before molding.

F-ICT researchers thought carefully about how and where to add automation to speed up downstream production steps. In use, they recommend an automated CNC cutter to cut plies from sheets of freshly made prepreg via preprogrammed patterns. Stacking could be done by hand for low-volume applications — possibly with laser-placement assist — with automation used for higher volumes. Robots equipped with Bernoulli grippers could pick up stacks and load them into the press, then remove completed parts (using vacuum grippers) and send them off to waterjet trimming and final finishing.

The team did a followup study to compare the mechanical performance and economics of InPreg/compression molding with conventional autoclave and vacuum-bag cure methods for making laminate composites (both using single-sided tools) and with fast wet-compression molding, using two-sided, hard tooling. For autoclave/vac-bag processes, the team used classical epoxy/carbon fiber UD prepreg with the same fiber/volume fraction as the prepreg produced via InPreg; a similar material was formulated for wet-compression molding.

The InPreg/compression laminates processed faster and were comparable to autoclave-cured laminates and superior to vac-bag laminates in void content and mechanical performance. Wet-compression molding was faster, but Inpreg/compression had better properties and fewer voids. F-ICT calculates that the cost of parts of comparable mechanical performance from InPreg/compression molding will run 45% more than those from wet-compression molding (with fewer voids and better properties), but only one-eighth that of autoclave-cured parts using conventional prepreg.

“InPreg offers many benefits vs. conventional prepreg [produced via hot-melt or solvent-based methods],” notes project leader and F-ICT thermoset technology head, Michael Karcher. “Production time and energy are reduced by eliminating freezing [used to stop the cure reaction during B-stage] and subsequent shipping and thawing prior to use. There are fewer process steps, since resin is applied directly to carrier films and fiber. Processing times can be reduced further once two-step (snap-cure) technology is applied to resin systems.” F-ICT researchers believe that compression molding is the most cost-effective process for high-volume composites processing because the presses don’t need the injection units, venting strategies or tooling action that injection or resin-transfer molding (RTM) require. And because resin is B-staged rather than liquid, the tool can be sealed with a simple gasket.

Further, InPreg/compression provides a lower-cost, faster-processing alternative to high-pressure RTM (HP-RTM) for parts with complex geometry. “Thanks to greater process flexibility, molders can control and adjust properties like draping and tack on the fly,” adds Karcher. “They also are better able to experiment with novel hybrid polymer systems that, for example, combine epoxy and urethane and are of great interest in the auto- motive industry. Further, molders gain greater control of the degree of pre- polymerization/curing after the initial reaction to create a B-stage resin. This combination makes the system attractive as a substitute for material/process combinations used in aerospace and automotive industries, and may open new market opportunities.”

The InPreg program is still in an early development stage, but the F-ICT team believes there are many ways to automate downstream process steps that will reduce costs and cycle times. Huntsman researchers believe they can modify the current four-part epoxy system to apply 2-minute-or-faster snap-cure technology, but say this will require new cure technology and additional development time and effort. Both organizations seek industry partners to move the InPreg program forward. In the meantime, Huntsman says it will sell the resin system to any interested party.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Automotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

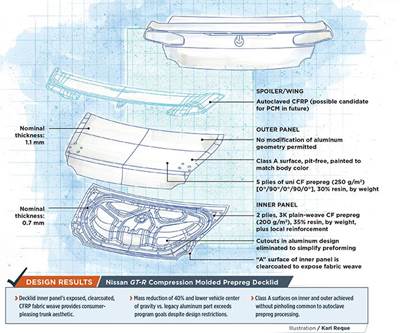

Read MorePrepreg compression molding makes its commercial debut

Ultra-thin, preformed laminate designs enable CFRP decklid manufacture at lower-than-expected mass and at cycle times approaching mass-production speed.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)