Prepreg compression molding makes its commercial debut

Ultra-thin, preformed laminate designs enable CFRP decklid manufacture at lower-than-expected mass and at cycle times approaching mass-production speed.

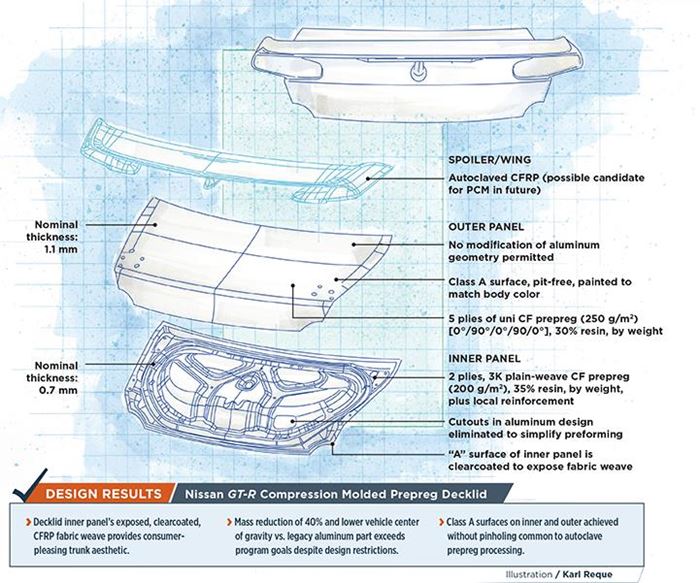

Design Results:

- Decklid inner panel’s exposed, clearcoated, CFRP fabric weave provides consumer-pleasing trunk aesthetic.

- Mass reduction of 40% and lower vehicle center of gravity vs. legacy aluminum part exceeds program goals despite design restrictions.

- Class A surfaces on inner and outer achieved without pinholing common to autoclave prepreg processing.

One of the biggest hurdles for automakers is developing faster production processes to mold laminate-based carbon fiber-reinforced polymer (CFRP) parts, particularly those with thermoset matrices, which need extra time to crosslink. Conventional autoclave-cured prepreg produces parts with exceptional mechanical performance, but is capital- and labor-intensive, generates significant consumables waste, requires a great deal of energy and has production cycles typically measured in hours.

Fortunately, in the past decade, out-of-autoclave (OOA) processes have been developed that offer autoclave-like performance and quality at less cost and several orders of magnitude faster cycle times (see the three articles noted under "Editor's Picks" at top right). One of these is prepreg compression molding (PCM), which makes use of specially formulated CFRP prepregs that are preformed, transferred to a conventional hot compression molding press, and become Class A parts.

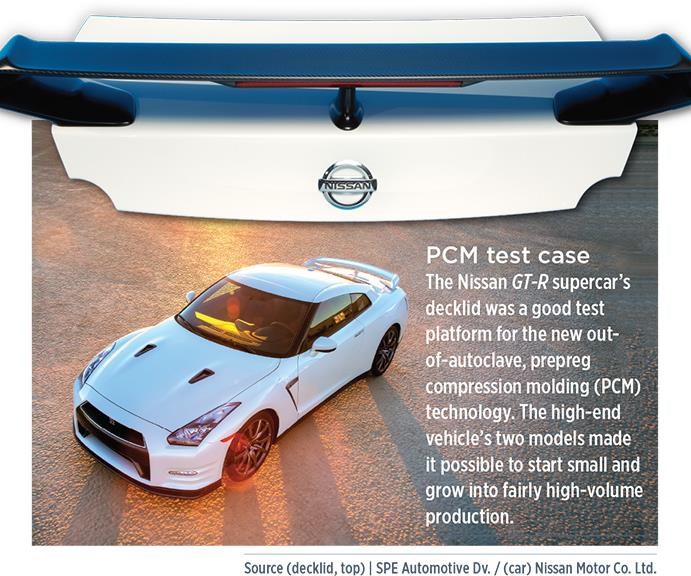

Developed by Mitsubishi Rayon Co. Ltd. (MRC, Tokyo, Japan), PCM made its commercial debut on 2014 model year decklid inner and outer panels for the Nissan GT-R supercar, produced by Nissan Motor Co. Ltd. (Yokohama, Japan). But the composite decklid’s successful debut was the result, in part, of resourceful design work under a somewhat restrictive set of goals and imperatives.

Developmental-turned-commercial part

Researchers at MRC started developing the PCM process and its special prepreg around 2007. During development, the viscosity of the prepreg’s epoxy resin was increased to prevent resin running out of the tool during high-pressure molding. Further, rapid-cure hardeners were used to achieve either a 3- or 5-minute cure — the latter offering longer shelf life at ambient temperatures. The 5-minute-cure prepreg grade used in this project, called Pyrofil TR361 E250S, was developed by MRC at its Toyohashi Research Center.

As work progressed beyond simple test plaques, researchers looked for a prototype automotive part with more complex surfaces to validate the material/process and to demonstrate to OEMs that the system made sense for high-volume part production. MRC had a longstanding relationship with Nissan, and the automaker, for its part, had its own aggressive programs for improving vehicle fuel efficiency. Because it recognized that CFRP held promise for mass reduction if cost and cycle-time could be managed, Nissan agreed to share with MRC the geometry and CAD files for the design of a decklid (trunk lid) on its flagship GT-R supercar. The understanding was that if MRC’s development work showed promising results, then Nissan’s engineering team would consider using a PCM’d CFRP part on an upcoming vehicle.

MRC’s design team worked with the GT-R decklid data between 2009 and 2011. At that point, both organizations believed the material/process had evolved to commercial-part readiness. The design for a 2014 GT-R model’s aluminum decklid was selected, and work on a CFRP version began in 2012.

Program goals & challenges

As the commercial program began, Nissan and MRC were joined in a team effort by system supplier Chiyoda Manufacturing Corp. (Ota, Japan), material processor Challenge Co. Ltd. (Sayama, Japan) and tooling supplier Yasuda Moldtec Inc. (Kinokawa, Japan). Goals were to produce a part with equal or better mechanical performance but at least 30% less mass than the benchmark aluminum assembly. Because this is a performance car often used on the racetrack, energy management/crash performance was important. Although the failure mode of CFRP parts differs from that of aluminum, the decklid must manage energy well enough to survive a high-speed rear collision, without shattering into small projectiles/debris.

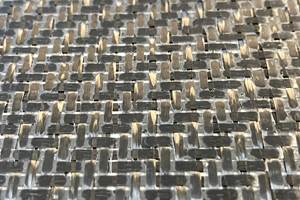

Molding speed also was important. Although the first commercial decklid was for the highest performance and, therefore, lowest-volume GT-R model, Nissan was interested in expanding it to higher volume models, and that required a fast process. Further, no one expected CFRP parts to be less costly than aluminum, but they had to remain affordable. Finally, aesthetics mattered. The decklid’s inner and outer panels had to meet automotive Class A requirements. The outer shell would be painted to match body color; the inner shell would feature clearcoated/exposed-weave CFRP, the imperfections of which would be readily visible.

These imperatives posed a challenge: This was a running change on the original aluminum part, that is, there was little leeway for significant alterations, let alone for a complete system redesign. In fact, no modification was permitted on outer panel geometry and only minor adjustments could be made to the inner panel. For example, the aluminum predecessor featured cutouts on the inner panel, but the team decided to leave them solid in the CFRP design because creating cutouts would take longer and complicate preforming. Other small changes were made to enhance stiffness and achieve appropriate failure modes during crash testing. The restrictions eliminated opportunities to consolidate subcomponents and integrate attachment hardware (which is bonded during final assembly), either of which could have helped reduce finishing and final-part costs.

Because geometry couldn’t be modified and the composite panels would be very thin — outer panel, 1.1 mm; inner panel, 0.7 mm — the team anticipated challenges, including handling the thin, preformed prepregs during transfer from preforming station to mold. Another worry was achieving a Class A surface on the inner panel, given its exposed weave and complex contours. It took much trial and error, but the fabric used on the inner panel worked well with minimal resin flow and fiber distortion.

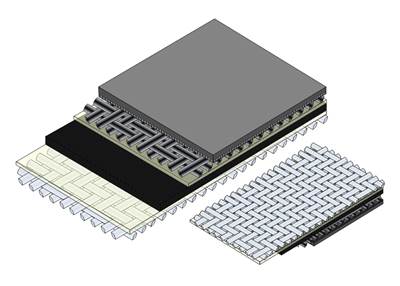

For the outer panel, five plies of unidirectional carbon fiber reinforcement (fiber areal weight of 250 g/m2; resin content of 30 wt-%) are used in a 0°/90°/0°/90°/0° layup. The inner panel features just two plies of 3K plain-weave carbon fabric (fiber areal weight, 200 g/m2; resin content, 35 wt-%), plus local reinforcement in several locations, using an additional two plies of the same prepreg.

The decklid was evaluated first, via computer-aided analyses and physical tests. For example, Nissan placed a fully assembled/bonded part in a special test apparatus and compressed it until it broke; this enabled comparison of failure modes for CFRP and aluminum assemblies. Results were used to optimize the design of the decklid’s inner panel and the bonding scheme. Durability (including repetitive open/close, ball impact and hot/cold and humidity resistance) was likewise evaluated. The capstone was a long-term driving test on Germany’s famed Nürburgring track (Nürburg, Germany). The driver reported the test car handled better with the lighter decklid, which lowered the vehicle’s center of gravity.

In production, prepreg is first layed up, debulked and cut out. Next, the prepreg is preformed by heating for 1 minute until it reaches 60-70°C and immediately shaping it in an air-cylinder press under light pressure (0.3 MPa) using a two-sided tool made from polyurethane modeling board. Preforms are then cooled to room temperature for a total preforming time of <5 minutes. An optional step, when aesthetics are critical, involves covering the preform with a silicone rubber sheet and pulling a vacuum to smooth out wrinkles prior to demolding. If they won’t be molded right away, they are stored in containers to keep their shape. Normally, a few preforms accumulate, press-side, before being molded. The molding cycle in a hydraulic compression press is 8 minutes at 140°C, using 8 MPa forming pressure.

Because both panels are molded to net shape, post-mold trimming is limited almost entirely to removal of a thin parting line flash. Thanks to high molding pressures, parts reportedly exit the mold with a very smooth surface and none of the pinholing seen in autoclave-cured parts. Only light sanding is done to ensure mold release residue is removed prior to painting. Demolded, deflashed parts are bonded together with an epoxy structural adhesive.

Interestingly, the decklid features a fixed CFRP spoiler/wing. On lower-performance GT-R models, the part is blow-molded in acrylonitrile butadiene styrene (ABS) and painted to match the body, but the premium model with the CFRP decklid features an existing autoclave-cured, clearcoated CFRP spoiler with visible weave. Although only the decklid was produced by the PCM process for the 2014 GT-R changeover, it’s possible the wing will be re-engineered for PCM on future models.

Challenge buys prepreg from Mitsubishi, cuts patterns, lays up laminates, preforms and molds inners, outers and the autoclaved spoilers, and then bonds the decklid panels. The unpainted assemblies are then shipped to Chiyoda, which paints the exteriors, clearcoats the inners and spoilers, bolts on the spoilers, and then ships the completed deck/spoiler assemblies to Nissan’s vehicle-assembly facility.

Many benefits

Despite the curbs on design freedom, the team exceeded its 30% mass-reduction goal, reducing weight by 40%. Mass-decompounding effects followed, thanks to assembly lightweighting: The lighter decklid opened and closed much faster with the struts used on the existing aluminum decklid, so Nissan switched to lighter struts and mounting hardware, reducing mass further. For the car owner, the CFRP decklid opens and closes with less effort, emissions are reduced, and fuel efficiency, aesthetics and handling (via the lower center of gravity) improve.

The PCM process reportedly can produce 84,000 parts per year per tool, using the 3-minute-cure prepreg, and 50,000 per year per tool, using the 5-minute-cure prepreg. That and the fact that PCM components can be molded on conventional — read, readily available — compression presses means CFRP is now accessible to more molders and practical for higher volume platforms.

Related Content

IPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MorePontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.

Read MoreFilm adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreRead Next

Class A CFRP body panels: Six-minute cure

Gurit CBS-based laminate/process combo mints parts with twice the thermal performance in one-sixth the time.

Read MoreSub-8-minute cycle times on carbon/epoxy prepreg

Globe’s Generation 2 RapidClave system passes another out-of-autoclave milestone.

Read MoreFaster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

Read More

.jpg;width=70;height=70;mode=crop)