Measuring thermoplastic prepreg tape quality for part process control

Low-cost tests measuring dimensions, thermal behavior and consolidation predict CFRTP part quality.

Both the aerospace and automotive industries are interested in applications using thermoplastic prepreg tapes. As might be expected, the quality of the finished parts is significantly affected by the quality of the raw material for the laminate. Though thermoplastic prepreg tapes have been used for decades, the push for quality has intensified as many seek to consolidate in-situ, without further application of pressure or heat. The French engineering and advanced manufacturing R&T organization Cetim (Nantes, France) has developed a system for quality assurance of these materials, which in turn, increases quality control for finished parts.

Tape quality necessary for in-situ consolidation

Cetim has developed several technologies for producing thermoplastic composite parts. One comprises a laser filament winding machine for thermoplastic prepreg tapes. The goal for the machine is to manufacture tank and tube applications that, until now, were limited to metallic and thermoset composite materials.

This thermoplastic winding process is based on the same concept as thermoset filament winding, but with a different, in-situ, consolidation step. For thermoplastic composites, a laser — such as that used with automated fiber placement (AFP) of thermoplastic prepreg tape — heats a specific area of the tape to increase the thermoplastic matrix to its melting point. In this melt temperature region, consolidation of the tape is achieved while the matrix is molten with pressure applied by a drum. Successive layers of the part are stacked and consolidated during winding.

However, as the industry has discovered during development of automated placement methods over the past decade, in order to produce parts with reliable properties and performance, it is necessary to understand the thermal and physical-chemical behavior of these thermoplastic tapes. For example, the tape must have constant dimensions and very low porosity to avoid temperature fluctuations during application that could result in poor consolidation between layers.

Thus, to succeed in its thermoplastic composite process development and to efficiently evaluate the quality of in-situ consolidated parts, Cetim has developed four quality assurance checks over the entire manufacturing cycle: dimensional (as received), thermal (as heated), inline (as consolidated) and the energy required to peel tape layers apart after consolidation.

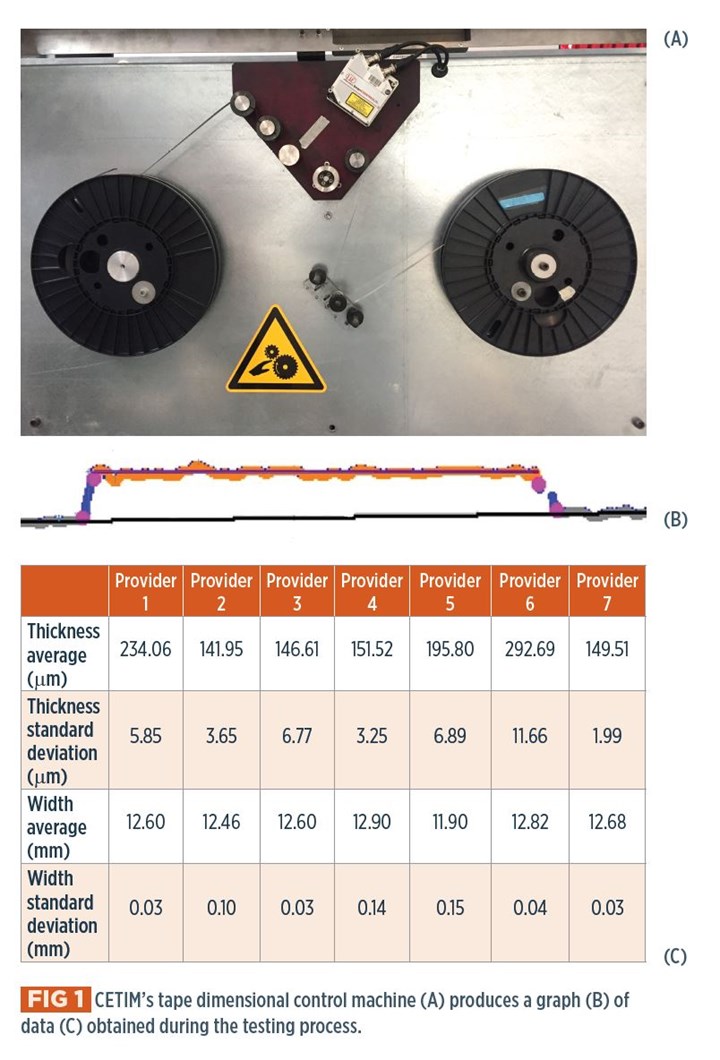

Dimensional control

This first check takes place before use. Its aim is to quickly evaluate tape thickness and width along its length. The testing machine is equipped with a laser, a camera to catch the reflected laser signal and a sensor to measure the unrolled length of tape. The process comprises unwinding tape from the as-shipped spool onto an empty spool. During this process, the laser and camera provide light data across the width of the tape and along its complete measured length. The processing software interprets the data and shows, in real time, a graph of variation in tape width along the x-axis and in tape thickness along the y-axis (Fig. 1). This makes it possible to visually detect width or thickness defects, and the machine software automatically shows alerts when dimensional tolerances are exceeded. After test completion, data of tape width and thickness variations is easily retrieved (table in Fig. 1), and it is also possible to apply statistical processing.

Thermal and micrographic controls

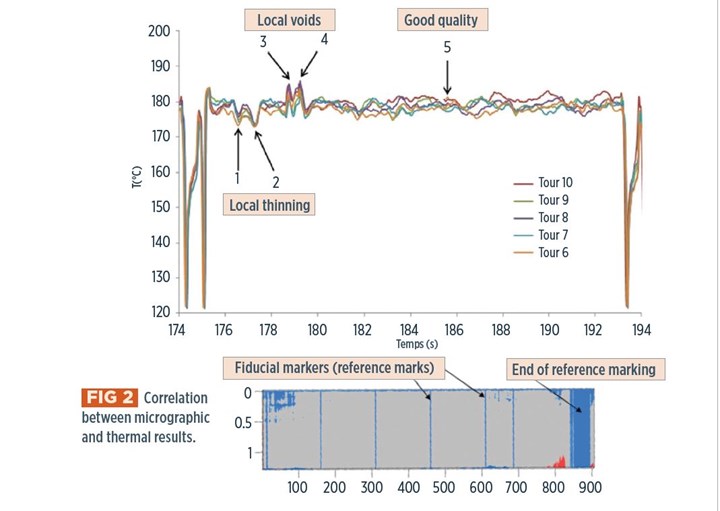

The second check evaluates defects that affect the tape’s thermal behavior during heating (in this case, by laser) including dimensional change, adhesion/delamination between fibers and matrix, porosity and surface condition before manufacturing. The technique comprises scrolling the tape in front of a low-power laser and using a thermal camera to capture an image of the temperature variations generated. These inhomogeneities in heating identify defective areas where porosity, dry fibers or surface roughness modify the local thermal behavior. After data processing, it is possible to obtain images that show a spatial representation of the tape’s thermal response (Fig. 2), including deviations, where red represents areas that are warmer and blue represents areas that are colder than the desired processing temperature.

It is also possible to show a graph of process time (x-axis) versus tape temperature (y-axis, Fig. 2). Cetim has correlated these results to porosity measurement from micrographs of tape sections. These are sections of tape as it is received and/or sections of final parts that are observed under a digital microscope, providing qualitative information such as fiber distribution, specific type of defects, porosity, etc. Though helpful to establish the correlation between tape temperature response and part quality, these micrographic inspections are expensive, destructive and only allow the tape to be analyzed section by section, not continuously over its entire length.

However, Cetim did complete this investigative work, correlating results from the tape’s temperature response test with micrographic section results. These results show the effectiveness of this rich control for thermoplastic tapes, and even more efficient data processing is being developed.

Inline control

This control consists of determining whether the part being produced is compliant directly, inline during the manufacturing process. This operation is based on direct monitoring of essential manufacturing parameters such as measured temperatures, laser power, tape speed and roller pressure on the tape. The digital processing of this data provides a visual and automatic synthesis of manufacturing quality.

CETIM has developed a dashboard to give an overview of the process parameters during the whole fabrication. Data analysis is done with MATLAB software and enables implementation of an alert threshold as well as zooming in on the out-of-scope area for analysis of the origin of deviation (for example, tape quality, geometric mismatch, or machine malfunction).

It is said to be particularly effective for monitoring production of parts with simple geometries (for example, a plate, tube or ring); however, it is more complex to generate for complex geometry parts.

Peel test

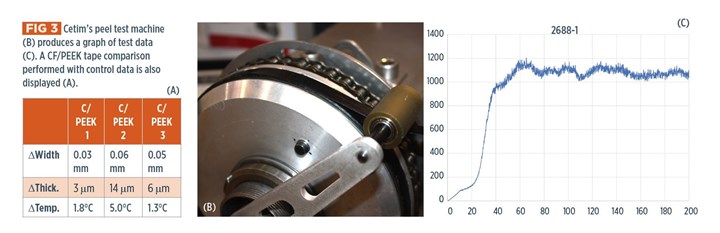

This final check has been developed by Cetim in collaboration with test bench specialist LF Technologies (Saint-Hilaire-de-Riez, France). It enables, in just a few minutes, the assessment of interlayer adhesion of the tapes. Measurements are made on specimens called "rings," which are manufactured by winding and in-situ consolidating several rounds of tape around a simple tube. These consolidated rings are then placed on the left drum of the test machine (Fig. 3) and unwound using the right drum. Multiple parameters may be adjusted including speed and peel angle, the latter via an arm with a roller at its end. Once the test is completed, an automated data processing system extracts the change in peel energy over the length of the unwound tape and graphs the data. This test enables a relatively quick and low-cost evaluation of optimal manufacturing parameters.

Increasing product and process control

Controlling the quality of thermoplastic prepreg tape enables composite part manufacturers to control the quality of their products. Non-compliance in one of these controls makes it possible to determine the origin of the problem and therefore to correct it effectively and quickly. Indeed, these checks provide a quality assurance flow chart of sorts:

- Does the problem come from the tape raw material?

Verify through dimensional and thermal checks correlated with limited section micrographic analysis. - Does the problem come from the manufacturing stage?

Verify through inline inspection and peel testing.

With these checks, Cetim can efficiently complete material benchmarks to select the most suitable tapes for a given application. The table in Fig. 4 illustrates one example, evaluating the best carbon fiber/PEEK tape for a high-performance composites application. Another example is still in process, Cetim’s evaluation of low-cost tape for the development of thermoplastic composite hydrogen storage tanks for future fuel cell vehicles. Cetim is engaged in R&D projects that evaluate the relative advantages of thermoplastic compared to current thermoset composite pressure vessels. Cetim works within the framework of private research agreements with several companies worldwide to develop application of thermoplastic in-situ consolidation.

About the Authors

Damien Guillon joined Cetim in 2009 after earning an aeronautical engineering degree and a Ph.D. on the crash behavior of composite materials. He worked as manager of the testing laboratory and as composite design expert before becoming R&D manager of the polymers & composites team.

Yoann Le Friant and Luc Poitevin joined Cetim as R&D project managers, in 2018 and 2017, respectively, after earning Master’s degrees in mechanical engineering. Le Friant’s current work includes lifetime prediction of polymer parts and control of thermoplastic tape quality. He is also in charge of Cetim’s material choice consultancy. Poitevin works on parts development for the space industry using thermoplastic processes and integration of complex functions.

Related Content

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More