Metal + composite = Less weight, more room

Global supplier develops scaled design approach for metal/composite hybrids in highly loaded automotive applications.

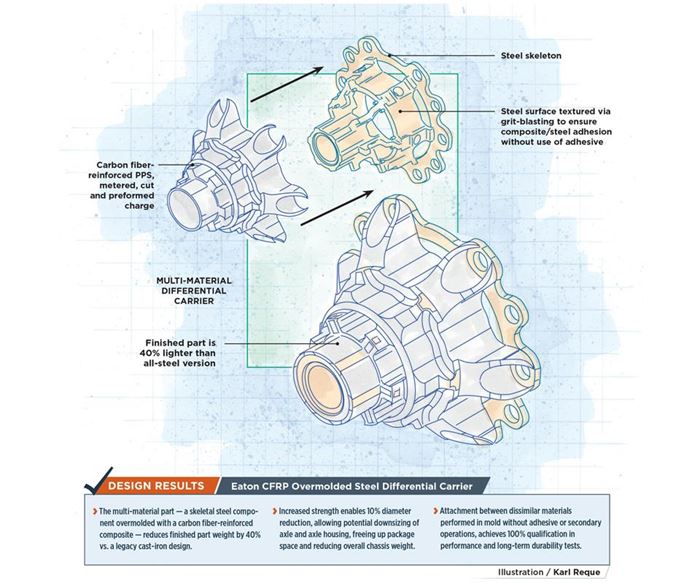

Design results:

- The multi-material part—a skeletal steel component overmolded with a carbon fiber-reinforced composite — reduces finished part weight by 40% vs. a legacy cast-iron design.

- Increased strength enables 10% diameter reduction, allowing potential downsizing of axle and axle housing, freeing up package space and reducing overall chassis weight.

- Attachment between dissimilar materials performed in mold without adhesive or secondary operations, achieves 100% qualification in performance and long-term durability tests.

A diversified supplier of hydraulic, electrical and vehicle components and systems for industrial, aerospace, automotive, marine and other mobility applications, Eaton’s (Dublin, Ireland) products include pumps, motors, valves, cylinders and filters, as well as the connectors and fittings necessary to integrate these into efficient solutions. In cars and heavy trucks, Eaton supplies everything from transmissions, traction control devices, superchargers and engine valves to fluid conveyance, fuel vapor management products (e.g., canisters) and plastic components. It has been developing a variety of metal-composite hybrid parts that reduce weight and provide a range of other benefits.

In a paper presented at SAMPE 2016 (May 23-26, Long Beach, CA, US), Kelly Williams, manager for polymer and nanocomposites materials and processing technologies at Eaton’s Corporate Research & Technology Center (Southfield, MI, US), discussed the design and manufacturing development of a steel and carbon fiber-reinforced thermoplastic differential carrier (Fig. 1).

Scalable mix of materials

With a background in polymers and composites, Williams’ 10 years at Eaton have been focused on how to get more composites into its products. Because the most attractive targets are parts that must endure heavy-duty loads and wear, her job is fraught with challenges. A differential, notably, distributes torque to an automobile’s drive wheels. Its name derives from its ability to allow drive wheels linked to a single engine and transmission to spin at different speeds when a vehicle is turning. The outer wheel travels a longer distance than the inner wheel, and so must turn faster. “Differential housings are high torque and high load-bearing applications,” explains Williams. “Using an all-composite construction would not be as durable as cast iron or steel. Thus, the challenge was, how can I match the current long- term durability and performance while saving weight with composites?”

Eaton’s response was to develop a design approach for the mixing of materials that can be scaled per part and program requirements. “We can use more composites for lighter weight, but this is also higher cost,” Williams explains. “So we have the alternative to scale back the amount of composites, use a little more steel and remain cost neutral. This is what we finalized for this project.”

Why steel and not aluminum? Williams’ team evaluated aluminum, steel and composites (glass and carbon fiber) in terms of stiffness and strength per weight (i.e., specific stiffness and strength), as well as cost per meter cubed. “Carbon fiber composites and steel offered the highest specific properties and lowest cost per volume of material,” Williams reports.

To decide where each material should be used, Williams’ team performed topology optimization analyses, using Optistruct from Altair Engineering Inc. (Troy, MI, US). “That is how we developed the load transfer design,” says Williams. “Very high load and torque goes through a steel frame, and medium-level loads go through the composite overmolding.”

Steel also is used where there can’t be any deflection. Williams explains that the differential housing holds pinions and gears: “Shafts go through it, so I have to control the housing dimensions. I can’t have creep or warpage, so I put steel in those areas which locate other parts, for example where gears have to mesh.” She points out that those were machined locations in any case, “so we left them metal, and we also left wear surfaces in steel to maintain long-term durability.”

Williams notes that this design approach could also be used for other Eaton products, such as pump housings and transmission casings. In fact, Eaton already has prototyped a number of hybrid metal/composites applications, such as transmission gears (see this month’s Applications story on hybrid steel/composite transmission gears and "Saving Pounds with Plastic-Metal Hybrids" in sister magazine Plastics Technology).

CFRP overmolded steel skeleton

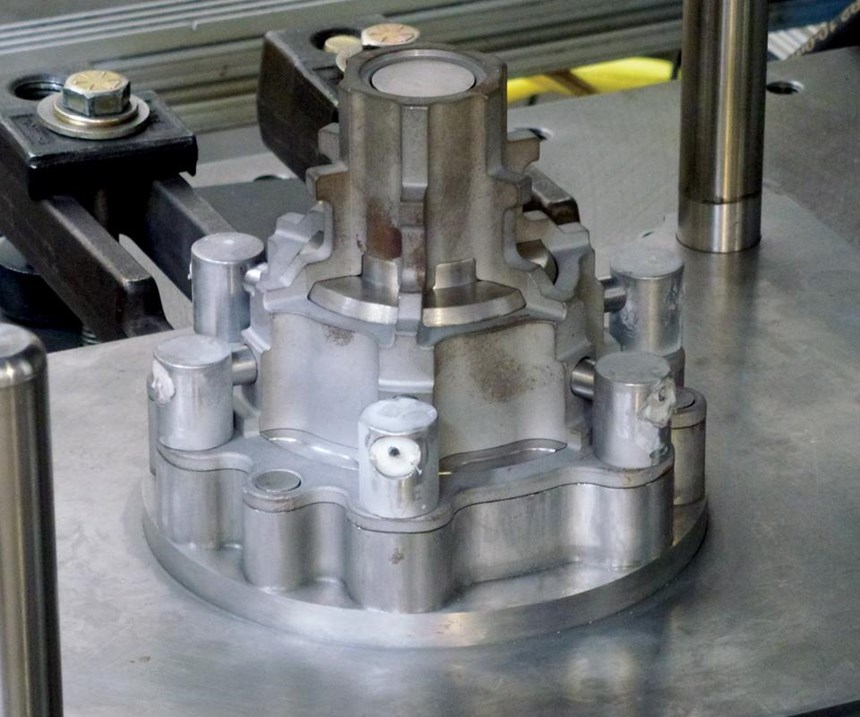

The final differential carrier design comprises a steel skeleton overmolded with carbon fiber-reinforced polyphenylene sulfide (PPS), the latter from thermoplastics supplier Celanese Corp. (Dallas, TX, US). The tradenamed FORTRON bulk molding compound is reinforced with fibers roughly 2.5 cm long and processed by Williams’ team in a compression molding press (Fig. 2). “We bolt the steel skeleton to the press, put in the hot-melt compound and overmold.” Skeleton placement on the bottom enabled good, concentric flow. The extruded charge placed onto the skeleton had already been metered, cut and preformed to shape.

Williams points out that because the differential is intended for passenger cars and light trucks — high-production-volume vehicles — the cycle time must be limited to minutes. “The exact requirement depends on the platform we’re producing the differential for, and how many machines we have available to run the part.”

The finished part not only cut weight but also reduced the differential diameter by 10%. “A reduction in diameter reduces the overall package size,” says Williams. The differential has to fit inside an axle and axle housing. Although Eaton only makes the differential, Williams notes that potentially reduced size here could cascade to downsize other parts, including the axle, axle housing and, eventually, the entire chassis.

The weight reduction effect is similar. Williams explains, “For a small passenger car differential, using carbon fiber composites, we can save roughly 5 lb (40%), and we can cut 12-14lb (40%) for a light duty truck. This could also cascade through, because the axle would not have to support as much weight and the chassis could also be lighter.” This could then impact wheels and suspension components.

Design/test of a robust bond

Eaton realized early on that one of the key challenges to multi-material designs is making sure the bond between the metal and composites is robust. To that end, it conducted cohesive zone modeling analyses with the University of Michigan (Ann Arbor, MI, US) to examine the metal/composite interfaces and predict the behavior of the structures in an effort to identify potential vulnerabilities.

Williams continued forward from this work, trying to minimize the amount of processing required to achieve attachment between the reinforced plastic composite and the steel. “We didn’t want to use adhesive in an extra step after molding the CFRP,” she explains, “so instead, we sought to bond during the molding process.” Her team then pursued mechanical interlocking in place of chemical bonding. They evaluated three options to increase surface area and encourage mechanical interlock: drilling holes in the steel, dimpling the steel and texturing the steel with grit blasting.

“It was decided that the through-holes provided a significant risk of decreasing the strength of the metal frame, of increasing the potential to initiate stress cracking, and would also be a high cost to machine,” Williams recalls. “This left the dimpled and textured methods.” Stress analysis revealed that the textured samples, prepared via grit blasting of the steel prior to overmolding, provided twice the target performance at the lowest manufacturing cost.

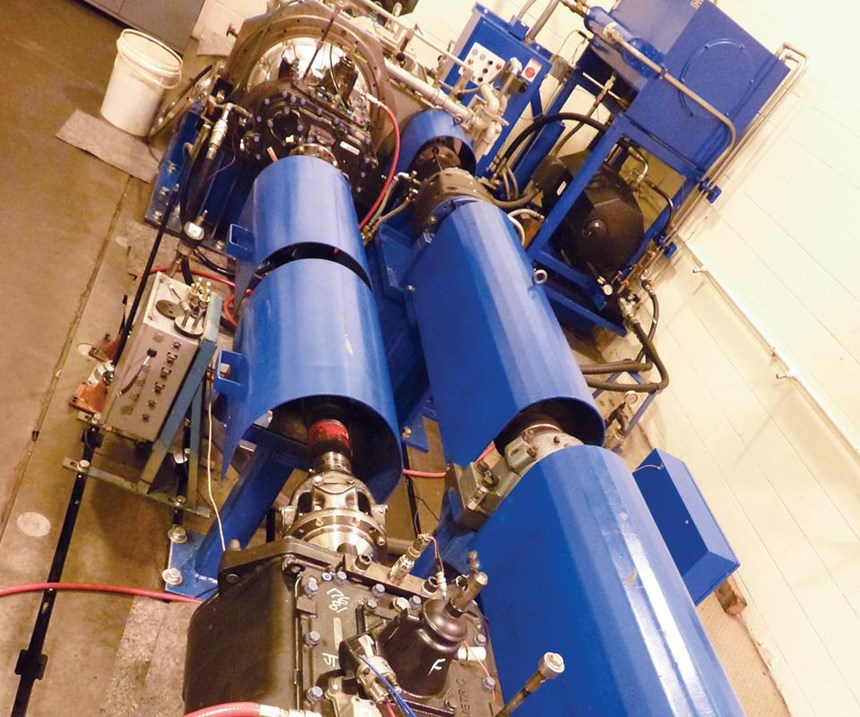

Williams’ team tested the steel-to-composite bond by subjecting the overmolded differential to cyclic temperature testing, examining whether or not thermal expansion would have a deleterious effect on long-term performance or durability. They also applied a frequency loading to simulate vibration, up to a maximum of 50 times the acceleration of gravity. Combining the cyclic temperature and vibration testing in a process dubbed “shake & bake” (Fig. 3), Eaton inspected the differential at set intervals for delaminations and found none.

Eaton also subjected the differential to dynamometer testing (Fig. 3). Used to measure the output of an engine, a dynamometer monitors torque and rotational speed. “Though we don’t subject this test rig to temperature differences, it does generate heat during the testing,” says Williams. Again, the test piece was inspected regularly, looking especially for debonding at the steel-to-composite joint. And again, the part experienced no debonding and achieved 100% qualification.

Manufacturing prove-out, new opportunities

Although Eaton’s success makes this development appear easy, it is important to point out that the work began in 2011. “We are re-evaluating this program now for commercial scale-up and viability,” says Williams, adding it is one of the projects that Eaton is pursuing through the Institute for Advanced Composites Manufacturing Innovation (IACMI), the public/private US composite materials and process development consortium with centers in Knoxville, TN and Detroit, MI, US (see “IACMI starting to walk the talk”). “We took this program to TRL 4,” adds Williams, noting that the goal now to is scale it up through manufacturing, and that work at IACMI is targeted to begin this month.

One notable change will be a move away from a thermoplastic to a thermoset composite, in collaboration with Eaton’s partner Dow Automotive Systems (Auburn Hills, MI, US). The original motivation behind thermoplastics was to achieve the required complex geometry in a low cycle time molding process. However, Williams explains, “We had issues with the thermoplastic’s stiffness and being able to control the dimensional stability.” She believes that Dow will be able to meet cycle time requirements while offering necessary improvements in part performance.

“We’ve proven that we can develop a range of hybrid-material part solutions and that these parts can handle drivetrain loads,” says Williams. Once the next phase of validating and scaling hybrid manufacturing processes is completed, Eaton’s expansive reach into vehicle and industrial applications should provide an exciting new realm of opportunities for composites.

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Hybrid steel/composite transmission gears

Scalable gear design trims heavy-truck weight, preserves wear life, controls cost.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More