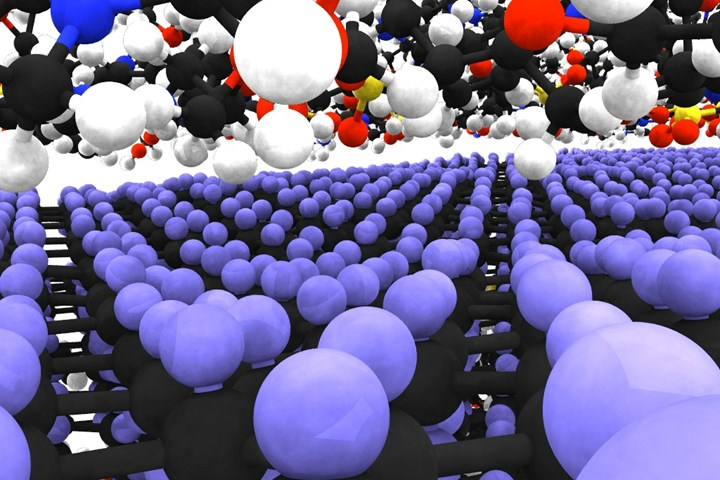

Modeling materials research. NASA’s US-COMP research institute is using simulation and modeling to develop composites that are three times stronger and lighter than current carbon fiber materials for next-generation manned spacecraft. This molecular dynamics model, developed by an MTU graduate student working on NASA’s US-COMP project, illustrates the type of modeling researchers are using to predict the behavior of the carbon nanotube-based composites they are developing. Here, a carbon nanotube (lower surface) is shown interfacing an epoxy molecule (upper surface). The colored spheres represent carbon (black), hydrogen (white), oxygen (red), nitrogen (blue), sulfur (yellow) and electrons (purple). Photo Credit: MTU

Under the Artemis program, NASA (Washington D.C., U.S.) aims to send the next manned crew to the moon, and, sometime after that, the first manned crew to Mars. Like most spacecraft built today, the primary structures of future NASA rockets will almost certainly comprise composite materials. But will today’s composites be strong enough to support interplanetary manned space travel?

The current answer is no, according to Greg Odegard, who serves as both the director of the NASA Institute for Ultra-Strong Composites by Computational Design (US-COMP) and the John O. Hallquist Endowed Chair in Computational Mechanics at Michigan Technological University (MTU, Houghton, Mich., U.S.).

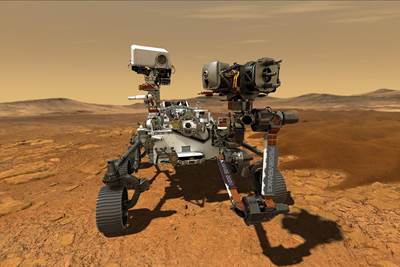

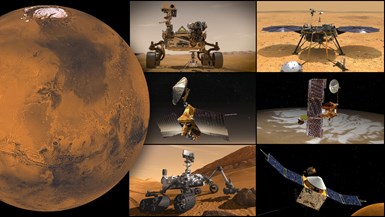

Odegard explains, “NASA wants to be able to put people on Mars, eventually. We can send a rover to Mars — we just did that recently — and that works out well. But to put a person on Mars is extremely expensive and difficult to do, because humans need food and water, space, air, all the essentials of life. Those things weigh a lot, and because it’s a lot of mass, you need more fuel [to power the spacecraft]. And the fuel itself adds even more mass. So, as it turns out, you send a person to Mars and the cost of fuel is incredible.” According to Odegard, it has been estimated that the fuel cost for sending a person to Mars is about $1 million per pound of cargo. Therefore, with multiple people and a significant payload, the total fuel costs can stretch into the billions.

To account for the extra payload, NASA has predicted that manned spacecraft components, such as rocket casings and fuselage structures, will need to be built from materials that are at least three times stronger and stiffer than current state-of-the-art carbon fiber composites, and as lightweight as possible.

Enabling manned Mars missions. NASA’s recent focus has been sending exploratory and data-collecting rovers and helicopters to the Martian surface (bottom images) while developing the Orion spacecraft (illustration in top image) for manned travel to the moon. The US-COMP Space Research Institute aims to deliver next-generation composites for NASA’s future plans for manned travel to Mars. Photo Credit: NASA

Working toward these goals, in 2017, NASA funded a five-year Space Technology Research Institute (STRI) called US-COMP. Combining the expertise of university professors, graduate students, industry researchers and NASA researchers, US-COMP’s primary research objective is to “develop a novel, ultra-high-strength lightweight structural material for use in deep space exploration vehicles.”

To accomplish this, US-COMP also aims to establish what it calls “a computationally driven material design paradigm for rapid material development,” which is Odegard’s area of expertise.

Led by MTU, which is in charge of coordination and has performed much of the computational modeling work, the US-COMP team also includes Florida State University (in charge of manufacturing), the Massachusetts Institute of Technology (MIT, materials development), the University of Utah (mechanical testing), Georgia Institute of Technology, Johns Hopkins University, the University of Colorado at Boulder, the University of Minnesota, Texas A&M University, Virginia Commonwealth University and Penn State University. Teams of faculty and students at each school are working on different parts of the program, mostly on the modeling side, Odegard explains. The materials are provided by industrial partners Solvay (Alpharetta, Ga., U.S.), Huntsman Advanced Materials (The Woodlands, Texas, U.S.) and Nanocomp Technologies (Merrimack, N.H., U.S.), a subsidiary of Huntsman that produces carbon nanotube (CNT)-based macro-scale fibers (see CW’s plant tour of Nanocomp Technologies’ facility for more information). Nanocomp is known for its Miralon brand of carbon- and CNT-based materials sold as yarns, sheets, tapes or dispersed products.

Odegard notes, “We have more than 20 professors, an uncountable number of graduate students and a few companies — it’s a massive, university-led team, working together for five years. It’s been a great opportunity.”

Model-based design to meet material requirements

US-COMP is working toward a very specific set of material requirements assigned by NASA, Odegard says. Specifically, they are aiming for tensile strength of 3 gigapascals (GPa) per gram per cubic centimeter, tensile modulus of 150 GPa per gram per cubic centimeter and interlaminar fracture toughness of 0.3 Newtons per millimeter.

To achieve this, the plan is to use CNT-based composites. Typically, CNTs used in composites are incorporated into a resin system in very small amounts, combined with a reinforcement fiber such as carbon or glass fiber. To get the properties that NASA is looking for, the researchers are investigating use of CNT-based reinforcement in place of carbon or another fiber.

Through investments in the U.S. National Nanotechnology Initiative, NASA has already successfully built high-performing CNT composite overwrapped pressure vessels (COPVs), and claims through separate research that certain CNT composites have exhibited up to 200 GPa tensile strength, 1,400 GPa modulus and 20% failure strain — this is compared to a reported 6.9 GPa tensile strength, 324 GPa modulus and 2% failure strain for high-strength carbon fibers like Toray (Tokyo, Japan) T1100GC and Hexcel (Stamford, Conn., U.S.) IM10.

Odegard adds, “Carbon nanotubes, on the molecular level, are well-assembled and ordered aromatic carbon structures that ideally have higher properties in both modulus and strength than state-of-the-art carbon fiber. That’s why people are so excited about carbon nanotubes, as they can potentially be a more high-performance reinforcement material than carbon fiber.” And, unlike other high-strength/modulus aerospace materials such as aluminum, titanium or steel, CNT materials are lighter than carbon fiber. “When NASA asked us to make a composite material that’s three times stronger than the state-of-the-art composite material, naturally the only way we can do that is with carbon nanotubes.”

Learning opportunity. Along with producing viable materials for NASA, the five-year US-COMP project has been a valuable learning experience for the student teams involved from various universities around the U.S. Here, Greg Odegard (top right) and a group of mechanical engineering graduate students at MTU examine data produced by a computing cluster at MTU. Photo Credit: MTU

Starting with these materials, the US-COMP team began using computational modeling techniques to simulate a variety of CNT material and thermoset resin combinations. “We knew from the beginning we were going to use carbon nanotube-based materials, but what we did not know is exactly what those materials would look like,” Odegard says. “We didn’t know what kind of polymers we were going to use with the composite. We didn’t know the form the nanotubes [needed to take].”

Computational modeling was used to evaluate and narrow down the variety of materials and formats, looking at various thermoset polymers and different formats of CNTs, such as CNT yarns, sheets and tapes. The modeling was meant to evaluate properties of the polymers and CNTs separately and, importantly, to simulate the interactions between various polymers and CNT formats prior to fabrication and mechanical testing of actual panels. As Odegard explains, computational modeling is performed at various “length scales,” starting at the atomic level (quantum mechanics), then the molecular level (molecular dynamics), then microscopic and meso-scale modeling of the interactions between polymers and fibers, up to finite element analysis-scale (FEA) modeling of composite parts themselves.

Five years later, Odegard says this modeling work has “finally led us to the point where we have a really good idea of how to design this material, what polymer to use, what type of carbon nanotube-based material to use and how to manufacture, and all of that has been driven by the modeling.”

The specifics are proprietary (and developments are also ongoing), but Odegard says the resulting material has been narrowed down to a CNT-based composite using a high-performance thermoset resin matrix. The fiber volume fraction (FVF) is said to be comparable to that of traditional carbon fiber-reinforced composites.

Panel fabrication, testing and beyond

Massive team effort. US-COMP coordinates the efforts of faculty and student researchers from 11 universities, three industry partners and NASA. Shown here, MTU chemical engineering undergraduate student Leif Odegard (Dr. Greg Odegard’s son, top image) runs a characterization test on an epoxy resin, and chemical engineering graduate student Aaron Krieg (bottom image) measures the mass density of a polybenzoxazine specimen. Photo Credit: MTU

While modeling and materials development have been going on, US-COMP has also been fabricating and testing panels using these materials. “We’re playing around with the material design both from a computational perspective, and in making actual panels at the same time,” Odegard explains.

In addition, US-COMP is also working on what Odegard calls a “unique approach” to composite structure fabrication, the details of which are also proprietary at this time. He notes that CNT composites behave differently during resin impregnation and part manufacture than traditional composite materials like carbon fiber — specifically, the mass-manufactured CNTs they are using are not able to achieve the same degree of fiber alignment as do carbon fibers, requiring additional processing. Thus, part of the US-COMP program has involved development and evaluation of fabrication methods to build small, coupon-level test samples. Computational modeling has also been used to test and tweak different methods. “The modeling tells us the physics of what’s happening at each length scale, and it tells us what manufacturing variables we can tweak in order to improve the properties at each length scale. Using modeling, we can virtually change the parameters much quicker.”

“We’re also developing new test methods,” says Odegard, because there aren’t a lot of standard test methods in place yet for CNT fiber-based composites.

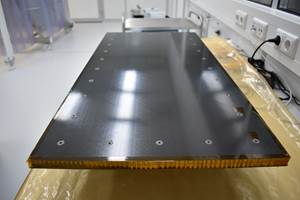

The goal by the end of the program in summer 2022 is to deliver 12 x 12-inch composite panels that meet NASA’s requirements for a three-times stronger and stiffer material, and are fabricated and tested on a laboratory scale — achieving technology readiness level (TRL) 4. Odegard says that US-COMP is currently on track to meet these goals, though he hopes to extend the project beyond this summer. Someday, he hopes to see these materials take off into space, as exterior rocket casings or fuselages, internal structures or cargo carriers, or on other structures, such as lander vehicles or habitats.

He summarizes, “What we’re trying to do is develop the next generation of composite materials for manned deep-space missions, using simulation to help improve the manufacturing of CNT-based composites. It’s modeling-driven design. We’re redesigning the composite from the ground up, really breaking away from the traditional composite design. The point is not only will this hopefully help us be able to manufacture CNT panels faster, but to manufacture better ones with better properties.”

Related Content

Carbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

Read MoreOn the radar: Reusable launch vehicles, hypersonics make space more accessible

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.

Read MoreComposite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreRead Next

Composites launch to Mars

NASA’s recently launched Perseverance rover and Ingenuity helicopter are supported by numerous composite materials and structures.

Read MoreNanomaterials: Products, supply chain mature for next-gen composites

Development spans 3D and thermoplastic nanocomposites, nano-CMCs for hypersonics and nanomaterials safety and toxicity.

Read MoreNanocomp Technologies Inc., Merrimack, NH, US

Its millimeter-length macro CNTs are finally realizing their commercial composites potential, with spacecraft applications leading the way.

Read More

.jpg;width=70;height=70;mode=crop)