Natural fiber composite drives automotive sustainability

Coir felt greens an EV, improves lives in developing world.

It’s not often that a car, let alone a car part, gets credit for saving a village. But that could be the case with the trunk load floor in Ford Motor Co.’s (Dearborn, Mich.) 2012 model year (MY) Focus Electric, the automaker’s first all-electric vehicle. This composite part is reinforced with coconut (coir) fiber, an agricultural waste product that otherwise has little value: It doesn’t burn easily. It’s unsuitable for livestock feed or bedding. And it’s slow to biodegrade, so it isn’t immediately useful as an agricultural soil amendment. But it is in plentiful supply. In villages from the Tropic of Cancer to the Tropic of Capricorn, it’s piled near coconut-processing facilities because the locals don’t have the resources necessary to rid themselves of husks and shells. That prompted College Station, Texas-based Essentium Materials LLC to find a way to capture this bio-waste, convert it into useful products and, thus, provide additional revenue for farmers in the developing world by offering manufacturers in the developed world sustainably sourced products whose prices are not tied to petroleum feedstocks or fluctuations in the futures markets.

Unusually useful properties

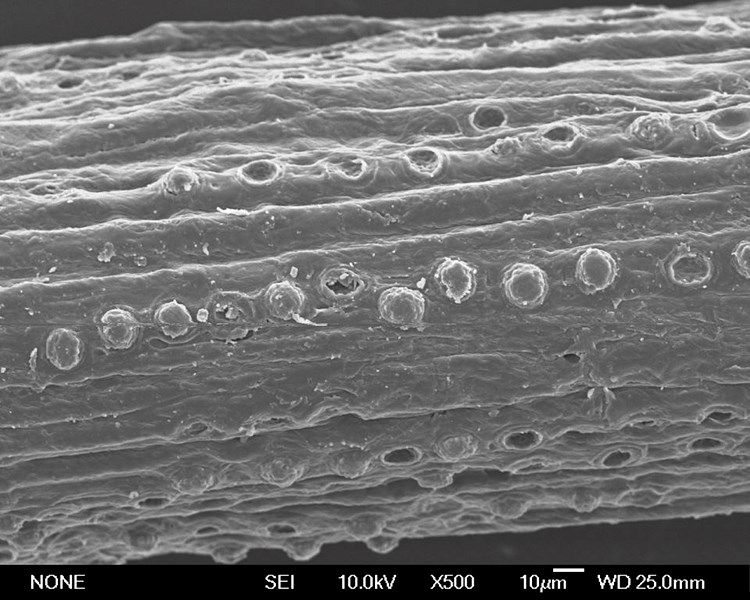

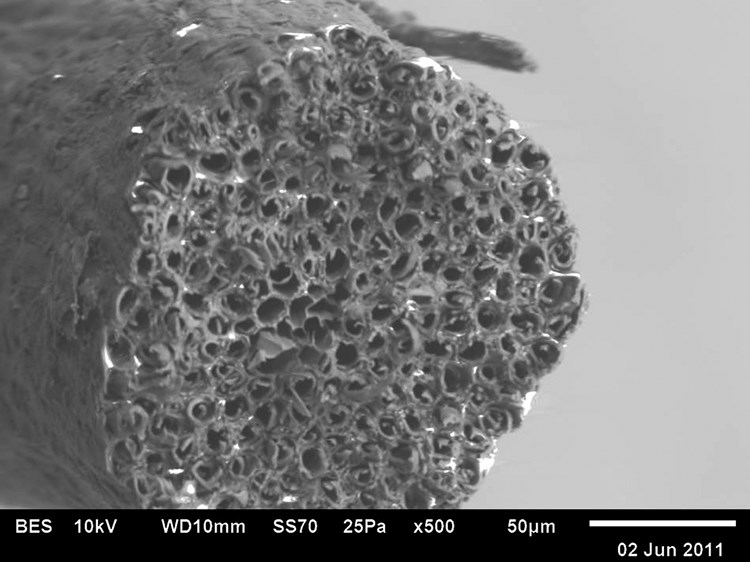

Coir fibers are extracted from a coconut’s outermost husk. “With an average diameter of 250 microns, coir fibers … are much larger than most other natural or synthetic fibers,” notes Ryan Vano, Essentium materials engineer, commercial development. “That means it’s inherently stiffer in bending, like a bundle of straws in cross-section, as well as strong and ductile.” Beyond good flexural modulus, coir also has among the highest lignin content of all the natural fibers, which helps make it flame resistant (important for vehicle interiors), unpalatable to microbes (odor and mildew resistant) and less prone to moisture uptake and swelling than many natural fibers. Moreover, it doesn’t take a lot of energy to dry coir after it’s been wet, which is helpful during extraction and processing prior to baling and shipping. “Another big benefit is its broad availability,” says Vano, pointing out that “50 billion coconuts are grown each year.”

Coir also exhibits consistent properties, regardless of coconut species, country of origin, soil and weather conditions, and time of harvest. This was verified in 2008 by Dr. Walter Bradley and his team of researchers at Baylor University (Waco, Texas), who asked, “How can we simultaneously make commercially viable products, help impoverished people and be better stewards of our planet’s resources?” The answer led to the formation of Whole Tree Inc., which, as it grew, was renamed Natural Composites Inc. and then was acquired this year by Essentium.

Essentium works in the Philippines with local partners to extract fiber near the original food-processing plants where coconut milk and meat were previously removed from coconut husks and shells. Essentium has its own processing plant in Indonesia.

The fibers are separated from the husk and other components by what’s described as a patent-pending, “mostly mechanical” process in which no chemicals are used. Then the fibers are processed and packed into shipping containers for a trip to the other side of the world where one of several nonwovens partners turns them into felt.

Its benefits notwithstanding, coconut fiber can’t be used alone. The stiff fiber resists entanglement even in the x and y axes, let alone the z axis. To promote entanglement, the coir fiber is commingled with thermoplastic polypropylene (PP) fiber, sourced from postindustrial recyclate (PIR) and supplied by Drake Extrusions Inc. (Martinsville, Va.). The fibers are blended in a 50/50 ratio, then carded and needled into felt, which is shipped in roll-stock form to the suppliers who make finished products.

Greening a green vehicle

Although she no longer recalls which company initially approached the other, Ford’s Elizabeth Johnston, product development engineer, Advanced Green Projects, recalls, “We had started to work with the coconut fiber and had realized how many great properties it has. That alone would have made it an interesting material to study. However, when you added in the social context, it just seemed like Essentium Materials and its products really encompassed so many of the things that are important to Ford.” Because Essentium had first targeted trunk liners, that became the initial direction of the Ford project, too. “We conducted the same kind of testing we’d do on a traditional material used on trunk trim — looking for issues like odor and moisture absorption,” recalls Gian Carlo Morlet Ugalde, Ford release engineer. “When the Focus Electric … load floor was suggested, we all jumped on it. We knew that using a natural material on an all-electric vehicle was a great fit.” This model’s low volumes were a plus because becoming an approved automotive supplier is neither a quick nor easy task, and a higher-volume platform, even a gasoline-powered Focus, could have been overwhelming for a start-up organization like Essentium.

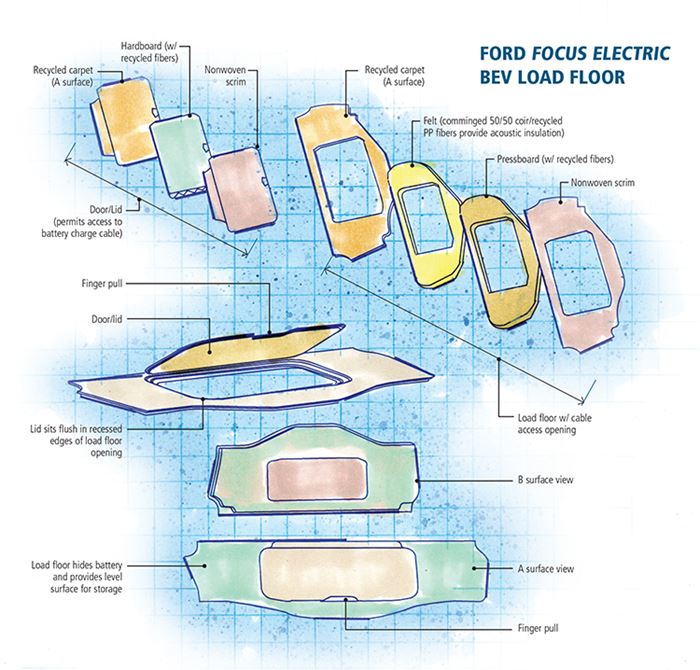

The Focus Electric’s load floor hides the battery pack at the front of the trunk by covering the space between the batteries and the trunk opening, and it provides a level surface on which to store items. Through a small door in the load floor, it permits owners to access the vehicle’s charging cable. And it helps prevent the transmission of road noise to the vehicle’s cabin.

After the program target was identified, testing went into high gear. “We have some pretty aggressive requirements for load floors to meet,” explains Bhavani Thota, Ford interior trim supervisor. “In use, the floor has to lie flat and fit well. While the body’s sheet metal supports it pretty well around the periphery, the center section of the load floor is unsupported. Nonetheless, it has to carry loads without sagging.” To confirm this, Ford engineers placed two 50-lb/23-kg sandbags next to each other in the center of the span and raised the temperature to 100°C (212°F) to check for deflection.

“The rear decklid glass puts a lot of sunload on anything in the trunk, so heat can be an issue and we do extensive testing on these parts,” Thota adds, noting that in another test, two sandbags are stacked on top of each other in the center of the peripherally supported load floor, which is then subjected to five days of extreme temperature cycling - from 100°C to -30°C (212°F to -22°F). “We look for creep and delamination,” he explains. “We measure deflection during the test and then 24 hours after the test is complete to make sure there is no permanent set. The floor must return to its original shape ±5 mm [±0.20 inch].” Additional testing evaluates deflection under a distributed load (that is, with separate loads in all four corners and in the center). To check abrasion and mar resistance, suitcases are dragged across the carpet face of the part. The coconut fiber-reinforced load floor passed with flying colors.

Notably, the load floor in question was not originally designed to use the coconut fiber pad. Rather, the initial plan was to use a cotton shoddy material containing some bio-component polyester resin plus recycled cotton fibers. Because the shoddy also is pressed into a mat before it’s incorporated into the final part, the switch was reportedly easy after the coir fiber passed testing.

Produced by one of the nonwovens partners, the commingled coir/PP felt is shipped to Tier 2 supplier AFTECH Advanced Fabricating Technology LLC (Rockford, Mich.) for die cutting, then the precut felt is sent to Tier 1 processor Autoneum North America Inc. (Farmington Hills, Mich.).

Autoneum stacks the precut materials: The A surface (recycled carpet) is placed face down on the tool surface, followed by a sprayed layer of styrenated block copolymer (SBC) hot-melt pressure-sensitive adhesive (PSA) from Bostik Inc. (Wauwatosa, Wis.). Then more adhesive is added, along with a layer of pressboard/press laminate that is also made with reclaimed fibers. Next comes more adhesive and the coir/PP felt. Finally another layer of adhesive is applied, followed by the B surface, a nonwoven scrim. The adhesive primarily tacks the layers together prior to die cutting.

The density and thickness are varied across the part by adding or eliminating pressboard, depending on whether more stiffness is needed or the part needs to be thinner. The porous lofted coir core is not compressed, so it provides noise, vibration and harshness (NVH) functionality.

A cable access opening is cut in the center (pressboard is left out of the stack around its perimeter), and in a postfinishing operation, a small door with a molded-in finger pull is mounted over the opening. The door is produced separately, in much the same configuration, but hardboard replaces pressboard for greater stiffness and durability. The door is mounted flush with the load floor surface so it won’t be torn off when heavy objects are pulled across the floor. The nominal floor/door wall thickness is 10 to 11 mm (0.39 to 0.43 inch).

Door to the future

In production for two years, the floor has worked well on the roughly 600 Focus Electric units sold in Europe and about 3,000 more sold in North America. And it’s been a good learning experience for all parties. “We don’t want this technology to be a ‘one-hit wonder,’” says Rose Petrella, Ford product development analyst, “so we keep evaluating it to see where else it can be used.” In fact, a second application already made its debut on last year’s Ford F-250 pickups — a coconut shell/bio-recycled structural guard injection molded in a thermoplastic elastomer (TPE). And both Ford and Essentium hint at another composite application to come in 2014.

Related Content

Syensqo introduces AeroPaste 1003 aerospace adhesive

Two-part room-temperature paste increases high-rate assembly and joining efficiencies when bonding metallic and composite parts.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreFilm adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreBelzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)