New technologies and companies at CAMX 2015

Final rundown of “finds” from CAMX, from technology for cutting composites and joining CFRP to metal for hybrid parts to companies offering training, textiles and NDT.

Fraunhofer (Munich, Germany) and Germany Trade & Invest (Berlin and Bonn) presented an array of “German High Tech Champion” composites technologies.

|

|

Remocut FRP uses lasers and high-speed beam deflection (top left) to cut organosheets (top right), 1-4 mm thick consolidated glass fiber/polypropylene (bottom left), 2mm-thick carbon fiber/epoxy tensile specimens (bottom center) and fiber placed isogrid structure (bottom right). SOURCE: Fraunhofer IWS.

Remocut FRP (name taken from “remote cutting”) enables high-quality lasers and high-speed beam deflection to achieve cutting or ablating (surgical removal of matter) of high-performance fiber-reinforced polymer (FRP) materials. A mirror system is used to rapidly project the laser beam onto the material, working with high precision even at high speeds (accelerations of 10g are possible).The high speeds result in very short interaction times between the laser beam and the material, minimizing heat effects.

Developed by Fraunhofer IWS (Dresden, Germany), this contactless thermal process offers a very flexible alternative to drilling and water-jet cutting, capable of cutting pliable textiles and preforms, consolidated semi-finished parts (blanks), trimming and contouring of finished parts, as well as hole-drilling and trimming of load-path optimized, fiber placement parts.

As an ablation tool, Remocut FRP can be used for pre-bonding surface preparation of composite-composite and FRP-metal joints.

Friction Spot Joining is one of several techniques developed by HZG for joining CFRP to metal for hybrid automotive construction. SOURCE: Helmholtz-Zentrum Geesthact

Friction Spot Joining (FSpJ) is a technique developed at Helmholtz-Zentrum Geesthact (HZG, Geesthact, Germany) for joining automotive aluminum and magnesium alloys to thermoplastic carbon fiber reinforced polymer (CFRP) structures, an enabler for automobile OEMs’ stated goal of hybrid multi-material vehicle construction in order to meet lightweight goals. FSpJ uses a non-consumable, cylindrical tool to heat up and join spot lap connections by friction. The joint is achieved by a combination of frictional heat deformation and chemical adhesive bonding between the surfaces. The technology is touted as fast, simple, energy-efficient and does not require consumables nor produce emissions. Other hybrid joining methods developed include FricRiveting and Injection Clinching Joining (ICJ).

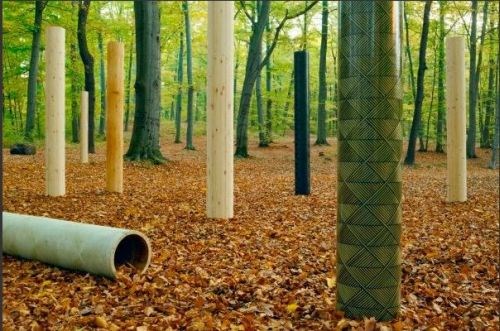

Aesthetic and eco-friendly fiber-reinforced plastic (FRP) wood composite columns show significantly increased load capacity with minimal reinforcement.

SOURCE: Peer Haller, TU Dresden

Professor Peer Haller at the Technical University Dresden in Germany presented his research on lightweight, textile-reinforced molded timber structures. The first part of the research is intriguing:

When compressed at 140°C across the grain, the cell walls of timber soften and fold up. As a consequence, the cell structure with its voids is compressed and the timber becomes more solid. No less significant, but currently not technically exploited, is the fact that the cell structure can be completely pulled apart again and fixed, which centuples elongation. In this way, timber becomes a cellular polymer material that can be easily formed.

This spawned a multi-step process for producing the structural wood forms. First, square-sawn timbers are biaxially densified using interlocking metal plates which transforms a continuous uniaxial closing motion into a quasi-biaxial compression. Densified square timbers are then planed, glued into blocks and sliced to form end grain plates. These plasticized end grain boards are then formed using heat, moisture and mechanical force into structural shapes, after which they are fixed via cooling and drying without any additives. Textiles laminated to the exterior strengthen the wood profile in the circumferential direction and protect against environmentally induced damage.

|

Production process for end grain boards: (from left) densification device, densified square timber, glued block and sliced end grain board.

SOURCE: “Textile reinforcement of multidimensional formable wood” by Jörg Wehsener, Thomas Weser, Peer Halle, Olaf Diestel and Chokri Cherif, TU Dresden, 2014.

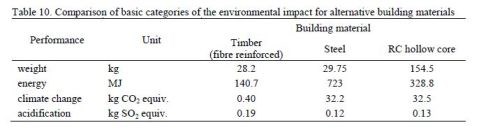

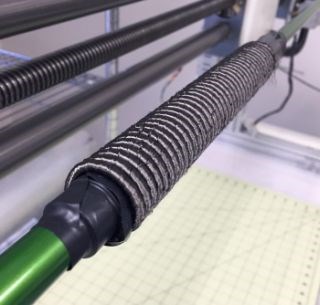

Tubular columns may be made using the above process and then applying textile reinforcement via braiding, filament winding or fabric wrapping. Fifty-two columns reinforced with glass or carbon fiber were tested and found to demonstrate significantly improved load-carrying capacity and ductility using a relatively small amount of reinforcement. The fiber confinement strengthens the wood across the grain, enabling the compression strength of the wood parallel to the grain to be fully utilized. Meanwhile, the wood increases the column’s section modulus with a lightweight, strong material which prevents local buckling vs. a thin-walled FRP tube. The two materials work together for a technology that is reportedly efficient, environmentally friendly, economical, recyclable, durable and aesthetically appealing. Results from a life cycle analysis compared to steel and concrete columns show a definite advantage with respect to energy use and CO2 emissions. Success in manufacturing large quantities of lightweight components in structural dimensions has been demonstrated in a pilot plant and Haller’s team is now engaging with industry to explore market applications.

SOURCE: “Structural, economic and environmental performance of fibre reinforced wood profiles vs. solutions made of steel and concrete” by C. Manthey & E. Guenther, A. Heiduschke & P. Haller, et. al., TU Dresden, 2010.

Carbon Flight was an eyecatcher that I omitted in my previous blog. Its developers claim a process for making hollow-walled composite tubes that have demonstrated 1.4 times higher later compression vs. traditional laminated tubes of the same weight and size. Reportedly manufacturable in any shape and size, other benefits include vibration dampening and insulation.

SOURCE: CW (left) and www.carbon-flight.com (right).

M51 Advanced Composites Training and Resources (Garran, Australia and Coppell, TX, US) is now offering a range of short courses in composites including:

- Introduction to Airframe Design (including composite materials)

- Composite Structures Design Requirements Analysis

- Composite Structures Damage Tolerance and Fatigue Analysis

- Composite Tube Design

- Inspection of Damaged Composite Components

- Essentials of Composite Materials for Engineers

All of these classes may be offered in Europe (Belgium/London), Australia (Canberra), Brazil (Sao Paulo) and near Dallas, Texas in the US. Courses are taught by Rik Heslehurst, a 30-year composites veteran with tenures as an aeronautical engineering officer with the Royal Australian Air Force, F/A-18 airworthiness engineer and Officer-in-charge of RAAF Materials and Process Engineering and lecturer/researcher at the Australian Defence Force Academy. Heslehurst has taught engineering courses for Abaris Training since 1991 and now adds these additional course offerings and his consulting services via www.efcomposites.net.

Textum offers innovative composite textiles. SOURCE: CW.

Another new composites company for me is Textum Carbon Solutions (Belmont, NC) which offers a wide range of innovative textiles for composites, including: woven and unidirectional fabrics, knitted and woven tapes, hot melt tapes, structural shapes and RTM preforms, as well as custom developments.

Vartega Carbon Fiber Recycling (Arvada, CO, US) also exhibited, highlighting its patent-pending solvolysis solutions for recycling of expired carbon fiber prepreg and long-fiber manufacturing scrap.

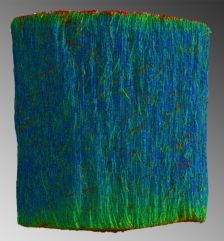

Finally, YXLON (Hudson, OH, US) showed its high-resolution, computed tomography (CT) inspection systems for composites. Supplying into the aerospace, automotive and other industries (e.g., sports equipment), YXLON is seeing increased demand for using this technology with composite materials. Its equipment offers a very precise and flexible means for understanding multiple aspects of composites, such as fiber orientation, flow analysis, porosity analysis and metrology.

CT is becoming a valuable tool for composite manufacturers. For example, Jesse Garant Metrology Center (Detroit, MI, US) offers CT services, using an array of customized equipment, which enable “walking through” the volume of a part in any orientation or direction for understanding issues like fiber orientation and fiber volume fraction, defect analysis which can detect and quantify every single void and also thickness measurement of every single wall in the structure, regardless of the number of cavities. In the latter, a plot of wall thicknesses compromised by porosity is output for easy visual evaluation, but the raw data is analyzed and available as well. CT can also perform dimensional checks, an order of magnitude more precise than coordinate measurement machines (CMM), by comparing the digital CT scan to the part’s CAD file. CT is also being used for analysis of part-to-part variation as processes are characterized and scaled to full-rate production.

CT inspection offers analysis for composite structures including fiber orientation (left), porosity (center) and part-to-part variation (right).

SOURCE: Jesse Garant Metrology Center.

Related Content

Syensqo introduces AeroPaste 1003 aerospace adhesive

Two-part room-temperature paste increases high-rate assembly and joining efficiencies when bonding metallic and composite parts.

Read MoreBiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreIPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MoreScott Bader, Oxeco partner for high-performance bonding solution

Joint technology breaks barriers to bonding lightweight flexible solar panels to roofing structures made from aluminum, coated steel and composites.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More