Not your father’s machine tools

HPC's editor-in-chief Jeff Sloan comments on the crucial roll manufacturers of drill tools play, today, in the ongoing effort to streamline the assembly of composite and metal structures using mechanical fasteners.

Until the Boeing 787 Dreamliner, Airbus A380, A350 XWB and the F-35 Lightning II fighter came along, it’s probably fair to say that most airframers viewed carbon fiber composites as one of many lesser-used materials that might show up on an aircraft’s structure. Until these planes were designed, composites were the exception, not the rule. Through the years, composites found use, but were usually relegated to flaps, tail fins, ailerons and similar structures — important, but playing second fiddle to legacy aluminum and titanium.

For those used to working with legacy materials — as averse to change as the rest of us — it was probably preferable that “new” materials remain in the niches they held. Metals offer a homogeneity and consistency that makes them predictable when it comes to drilling, routing and cutting. The opposite is true of composites. They are heterogeneous, with a capacity for endless variations in fiber type, fiber form, resin type and composition and fiber/resin ratio. As long as composites remained at the margins of aircraft structure, such an exception to the rule was … manageable. The job of drilling, cutting and machining them fell to a small group of experts who had developed specialized machine tools that were unlike any in the machine tool world. These folks operated in the margins, happy to help the rest of the manufacturing world cope with this challenging material.

Today, however, the tide has shifted … possibly for good. Carbon fiber composite structures are no longer the exception when it comes to high-strength, lightweight aerostructures. Some manufacturers, who were used to machining metals, have suddenly been asked to start machining composite laminate, and a lot of it. And the composites machining expert has just as suddenly become a very hot and rare commodity.

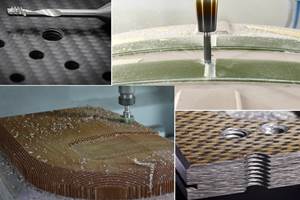

Although the A380 and 787 are in service, the F-35 is in testing, and the first A350 XWBs are on the assembly line, their manufacturers are still learning what it takes to effectively and efficiently machine, route and drill composites. As Ginger Gardiner reports this month in our cover story, “Hole Amibitons? Optimize! Customize!”, the dimensional specs for drilled composites are not only hard to hit with precision because of the variable resin/fiber mix, but ongoing advances in their resin and fiber technologies present a moving target as well. If that weren’t enough, the trend is toward pre-assembly of, say, a carbon fiber composite wingskin to its aluminum/titanium skeleton before drilling. To do this, and to save steps, airframers are attempting the near-impossible: use of a single machine tool to drill through three layers of vastly dissimilar materials — quickly, cleanly and repeatedly.

For the uninitiated, used to machining metals, the tendency is to draw on experience and use the same machine tools to work with composites. What’s required, however, is a tool optimized for composites. To that end, machine tool supplier Sandvik Coromant burnished its composites expertise with the acquisition in 2008 of composites machine tool specialist Precorp Inc., based in Utah. And other suppliers are coming in from the margins, working with receptive arframers to develop tool materials and geometries that cope effectively with highly abrasive composites.

Because it’s a postmold process, machining and drilling are performed on a composite structure that has already acquired most of its enormous value. Thus, a poor machining job puts thousands of dollars of product at risk; drilling and machining with tools and methods appropriate to the material are paramount.

Spreading the word about how best to machine composites can’t happen fast enough. We’re happy to do our part (see HPC's feature article on drill tools, titled "Hole amibitons: Optimize! Customize!" under "Editor's Picks" at top right).

Related Content

From the CW Archives: Drilling is not for the faint of heart

This edition of From the CW Archives revisits CW’s first plant tour — a visit to the F-35 FAL in Fort Worth, Texas — and a story by Ginger Gardiner a few years later. Both offer lessons on how to perform stacked drilling through composite and metallic materials.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreATL Composites collaboration advances kite-foil board production for Paris Olympics

Breiana Whitehead, pioneering Australian kite-foil sailor, spearheads board design intricacies with ATL Composites to enhance her performance ahead of the July 2024 competition.

Read MoreC.R. Onsrud breaks ground for machine shop expansion

Multi-phase expansion includes 9,900-square-foot addition to facility and purchase of new equipment to better serve aerospace, marine, composites and other industries.

Read MoreRead Next

Optimizing, customizing composites hole drilling

Matching the drill tool to the job can save thousands of man-hours and millions of dollars.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpeg;maxWidth=150;quality=70)

.jpeg;maxWidth=300;quality=70)

.jpeg;maxWidth=400;quality=70)