Nothing gets attention like a demonstration

CAMX 2014 showed that one of the best ways to prove a technology is to run it. Live and in person.

At CAMX, RocTool demonstrated the compression molding of a carbon fiber/polypropylene preform supplied by MIT RCF to make a tablet computer case back.

If you go to a machine tool or plastics trade show, one thing you notice immediately is that every manufacturer of primary machinery (CNC machines, injection molding machines, blowmolding machines) not only has a large booth filled with equipment, but that equipment is also running, producing products and showing the capabilities of the technology and the exhibitor.

At a composites exhibition, however, this is typically not the case. Composites manufacturing is often not conducive to a trade show environment, where resin application can get messy and smelly, especially in open-mold processes.

The evolution toward closed-mold processes might be changing this trend, however. For the last several years, most of the world's major composites trade shows have featured demonstrations of some sort, designed on the one hand to educate attendees about how to use a given process, and on the other hand to sell a product — resin, fiber, equipment, supplies, oven, etc.

CAMX 2014 (Oct. 13-16, 2014) demonstrations proved this trend well, featuring a large, enclosed demonstration booth operated by Composites One and the Closed Mold Alliance. Accompanying this was RocTool, which molded tablet computer cases in its booth, and MarkForged, which proved the capabilities of its 3-D continuous fiber additive manufacturing system.

RocTool preform, before and after molding.

RocTool, which manufactures compression and injection molding systems that use induction-heated molds for fast heating and cooling, garnered much attention at CAMX, where it molded 0.8-mm/0.03-inch thick tablet computer cases using preforms fabricated with material supplied by Materials Innovation Technology Reengineered Carbon Fiber (MIT-RCF). The preforms featured MIT-RCF's reclaimed carbon fiber nonwoven at 35 percent loading comingled with a polypropylene (PP) fiber. Preforms were inserted into the mold and heated from 150°F/66°C to 420°F/216°C in 60 seconds, followed by a 60-second hold and a 90-second cool-down for demolding. Advantages of the system include cost-effective nonwoven material, thin walls, resin-rich surface due to induction heating, cost-effective PP resin system, fast cycles, minimal warpage and minimal scrap. The mold for the demo was provided by ComDel Innovation (Wahpeton, N.D.).

Composites One technicians demonstrate infusion molding of a carbon fiber/epoxy unmanned aircraft top panel on the show floor at CAMX 2014.

Composites One and its Closed Mold Alliance demonstrated a variety of manufacturing processes, including infusion, resin transfer molding (RTM) and light RTM. Each was setup as a tutorial, designed to help attendees not only see how each process is used, but also understand best practices — where to inject resin on a given part, how to use pumping equipment (supplied by MVP), how to cope with corners and tight radii, and what to expect as a resin front moves through different fabric types and densities.

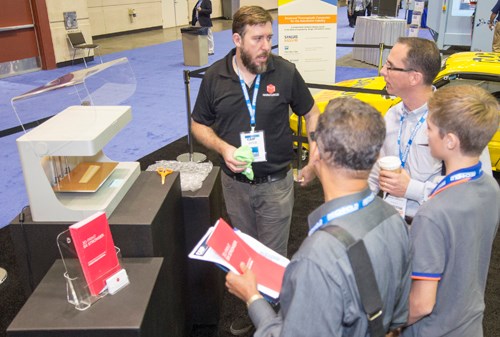

MarkForged's Mark One continuous fiber 3-D printer drew steady traffic at CAMX 2014. The machine dispenses polyamide or polylactide resin from one print head, and a continuous (proprietary) towpreg from the other print head.

MarkForged had almost continuous traffic at its booth, where the company demonstrated the capabilities of its Mark One additive manufacturing (AM) 3-D printer, which produces parts made with continuous carbon fiber in a thermoplastic resin. The Mark One has two print heads, both designed and built by the company. One dispenses polyamide (nylon) or polylactide (PLA) resin, and the second dispenses a continuous towpreg, either carbon or glass (dispensing of aramid fiber is in development). The towpreg is made in a proprietary process: A single carbon filament is coated with a specially developed thermoplastic resin, designed specifically for the printer. The Mark One uses fused deposition modeling (FDM), an extrusion-like process, for placement of resin and towpreg in the flat x/y plane of the part. The company says that the fiber can be oriented, or added selectively only where needed, in the x/y plane, but notes that, at present, vertical, or z-directional, orientations aren’t possible. Each build layer is approximately 200 microns thick. CAMX attendees were clearly enthralled and energized by the technology, which is in its infancy and certainly could prove to be highly distruptive.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More