Orion re-entry system: Composites displace metal

World’s largest heat shield updates metal design with out-of-autoclave process.

Design Results

- New high-temperature, out-of-autoclave prepreg system replaces titanium in facesheet structure, saving material cost and manufacturing time.

- Software suite optimizes laminate design, cutting weight, and interfaces with automated ply cutter, streamlining production.

- Superior thermal performance of new prepreg permits the use of less ablative insulation for overall capsule system weight savings.

It’s all about taking the heat — and the cold. Since the beginning of human space travel, space vehicles have had to insulate their occupants from the extreme heat and cold of space and protect them from the searing temperatures of reentry into Earth’s atmosphere. Prior to the Space Shuttles, with their heat-resistant tiled wings and underbodies that enable conventional winged landings, the U.S. National Aeronautics and Space Admin. (NASA) relied on capsule-type vehicles that plummeted to Earth in reverse, slowed and protected by a robust, one-piece heat shield that not only could endure extreme heat but also could absorb splashdown energy during ocean landings. The largest of these capsules carried three-man crews into Moon orbit for NASA’s Apollo program in the 1960s.

In 2006, as the Space Shuttles neared retirement, NASA launched its Constellation program. A team headed by Lockheed Martin Space Systems Co. (Houston, Texas) was assembled to design and build a replacement for the Space Shuttle, dubbed Orion. The new spacecraft would be capable of transporting a crew of six to and from the International Space Station, the Moon and, eventually, Mars.

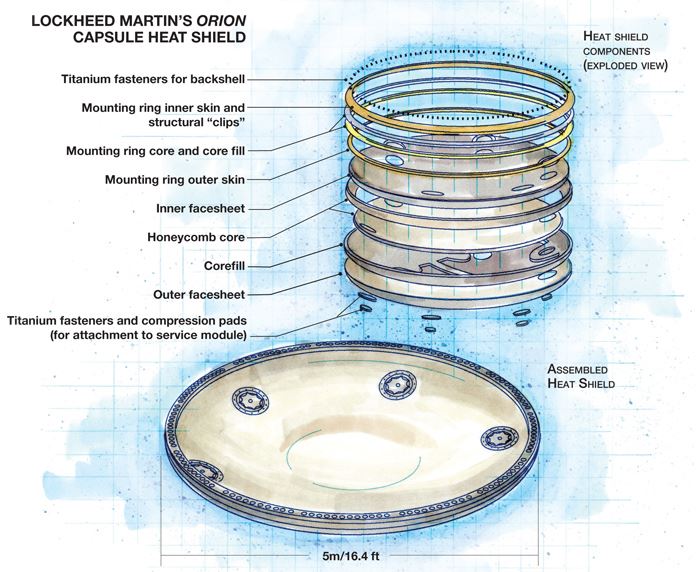

To maximize the interior volume in the Orion crew cabin design, Lockheed Martin and its Orion partners took a page from space history, opting for a classic “blunt body” shape, similar to but quite a bit larger than that used for the Apollo craft. As a result, Orion is equipped with a massive 5m/16.4-ft-diameter heat shield.

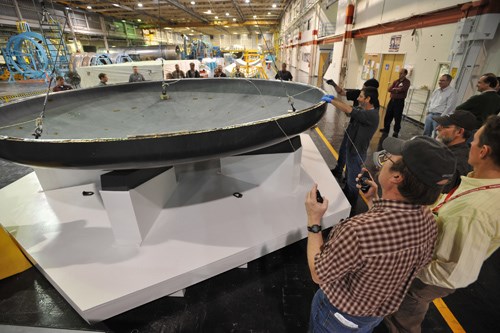

HPC recently had an exclusive opportunity to visit Lockheed Martin’s Colorado facility to learn about how the heat shield was designed and fabricated. Although Constellation has been scuttled in anticipation of the Obama Administration’s proposed NASA budget cuts, the Orion capsule, at press time, received a reprieve (see HPC's news update on the Orion reprieve and other NASA budget issues in"Obama relents ...." under "Editor's Picks," at right). The capsule is nearly complete , and its heat shield is an impressive engineering achievement. (For a related story on NASA's parallel all-composite capsule demonstrator project, the Composite Crew Module, see "Editor's Picks.")

Building on tradition

The Orion heat shield is the latest in a legacy of successful composite heat shields designed and built by Lockheed Martin Space Systems and is the largest ever built for manned and unmanned missions. “Orion has allowed us to take lessons learned from our long history with composite heat shields and push the envelope one step further, with new cutting-edge materials and out-of autoclave technology,” notes Colin Sipe, Orion ground test article thermal protection system design lead. “The result is a lighter part that makes the entire capsule more mass efficient.”

The shield’s design requirements were considerable, explains Sipe. At launch, it has to survive incredible vibration loads without fatigue failure. In space, it must deliver thermal performance sufficient to protect astronauts from the extreme temperature variations of space and withstand impacts of micrometeorite orbital debris (MMOD), which could damage the shield, compromising re-entry. During re-entry, with help from added ablative thermal barriers, the shield must not melt or burn, despite 5,000°F/2,760°C heat. And finally, as the capsule makes its final descent, suspended below the re-entry parachutes, the shield must withstand a 40-ft/sec (12.2 m/sec) controlled crash into the sea.

Sipe and a team, headed by Lockheed Martin’s Orion Thermal Protection System manager Jan Thornton, started with a legacy heat design but were determined to make it better. Previous designs consisted of titanium sheet metal skins over titanium honeycomb. Pro/ENGINEER 3D CAD software from Parametric Technology Corp. (PTC, Needham, Mass.) was used to design the part, and Nastran and FEMAP finite element analysis (FEA) software from NEi Software (Westminster, Calif.) helped determine whether the part could meet the structural design loads. LS-Dyna FEA modeling software from Predictive Engineering Inc. (Portland, Ore.), originally a car crash simulation tool, was used to determine if the dish would handle water-landing loads.

Based on these analyses, a composite heat shield was created, which consists of several parts. Its one-piece, curved dish is a sandwich structure, featuring composite skins, with a titanium honeycomb core supplied by Benecor Inc. (Wichita, Kan.). A mounting ring made from the same sandwich materials is adhesively bonded to the upper edge of the dish with 48 solid-laminate structural clips around the dish’s circumference to form a flat surface for attachment to the Orion capsule’s outer composite “aeroshells” or protective panels, called the “backshell.” Sipe adds that because the re-entry parachutes cause the capsule to descend at an angle, one side of the heat shield hits the water first. To ensure sufficient strength but keep shield weight to a minimum, the design is asymmetrical, with additional plies and a stronger honeycomb on the leading edge of the heat shield. Further, because the capsule will be attached to the service module situated below it within the launch vehicle, six large compression pads of ablative material, with titanium bolts in their centers, will be positioned on the underside of the dish at those attachment points. Additional thermal barrier material around the pad margins will ensure the integrity of the dish.

In search of the right material for the new design, the team worked with TenCate Advanced Composites USA (Morgan Hill, Calif.) to convert a space-capable, autoclave-curable, high-temperature prepreg system for out-of-autoclave processing due to the part’s size. Over an 18-month period, during which thousands of coupons were subjected by Lockheed Martin Space Systems’ testing laboratory to extreme environments that simulated a ballistic re-entry from a lunar mission, the Lockheed Martin team selected an intermediate modulus carbon fiber/cyanate ester prepreg developed by TenCate. “The new prepreg had a significantly higher service temperature than any other material candidates,” Sipe reports. “That allowed us to design a thinner thermal insulator on the outside of the heat shield, which resulted in a lighter overall mass for the Orion spacecraft.”

Although the heat shield that will fly will feature a 5-harness satin weave prepreg and a 2-inch/50-mm-thick Benecor titanium honeycomb core thermoformed to the correct dish curvature, the ground test article described here was made with less-expensive materials to save development costs and time. The team substituted a plain-weave prepreg, and used a more flexible aluminum honeycomb called Flexcore (Hexcel, Dublin, Calif.), with a cell pattern that conforms more easily to compound curvatures.

Streamlining production

For the heat shield’s facesheets, says Sipe, the layup was designed as a rosette, with triangular gores of prepreg placed like the petals of a flower around a circular center section. The fiber architecture and layup strategy were developed with the assistance of FiberSIM software from VISTAGY Inc. (Waltham, Mass.), which took the design data produced in Pro/ENGINEER, Nastran and LS-Dyna and optimized the laminate to avoid wrinkles while using the smallest quantity of material possible, reports Jerry Brown, the thermal protection team’s manufacturing lead. “FiberSIM also seamlessly integrated with our automated ply cutter,” he adds. The cutter, from Eastman Machine Co. (Buffalo, N.Y.), produced layup kits “in a matter of days. It would have taken our technicians about two weeks to manually cut all the materials for the dish layup.”

The Invar layup tool was fabricated by Coast Composites Inc. (Irvine, Calif.), a supplier Sipe singles out for particular praise: “They were great to work with and made a fabulous tool.” Hand layup was facilitated by a laser projection system from Laser Projection Technologies Inc. (Londonderry, N.H.) that interfaced with the FiberSIM software for more accurate ply placement. The dish laminate was built up in stages in about 10 weeks. Debulk cycles under a vacuum bag were performed every evening, reports Sipe. During that time, the outer skin was oven cured first, under a vacuum bag, for about 12 hours. A second cure cycle followed placement and bonding of the core, followed by cure of the inner skin in a third oven cycle. The syntactic core fill and adhesive materials, also from TenCate, were compatible with the prepreg. Airtech International Inc. (Huntington Beach, Calif.) provided the bagging consumables.

At HPC press time, the cured 1,000-lb/455-kg dish had been machined and was ready to receive its mounting ring, structural clips and additional thermal protection. Although the ground test article will have only a foam simulator added, Sipe and Thornton report that the actual flight capsule will be treated with Avcoat ablative material from Textron Defense Systems (Wilmington, Mass.), first used on Apollo-era heat shields. Designed to ablate (erode) during re-entry but leave the underlying composite dish undamaged, Avcoat comprises a silica fiber-filled epoxy novolac resin slurry that is injected into the cells of a fiberglass/phenolic honeycomb then adhesively bonded to the dish’s underside. “About 30 percent of the Avcoat will burn away,” Sipe notes, pointing out, “The good part is that less Avcoat will be needed because of the better temperature performance of the new prepreg.”

The completed heat shield is slated to ship this summer to Lockheed Martin’s Michoud Assembly Facility (New Orleans, La.), where it will be installed on the ground-test capsule for vibration, acoustics and water-landing tests.

“We have been able to meet our performance requirements,” Sipe concludes, “with a lighter and more cost-effective composite design, saving considerable weight for the overall system.” Says Lockheed Martin VP and Orion program manager Cleon Lacefield: “We achieved a $10 million cost savings and improved the project schedule by 12 months.”

Read Next

Simulation simplifies fabrication of all-composite crew module

Specialized simulation software shortens development cycle on first all-composite crew module demonstrator for NASA space program.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More