Plant Tour: FiberCore Europe, Rotterdam, The Netherlands

From debond-proof bridges to cost-saving infrastructure rehab, InfraCore technology is establishing composites as the fourth major construction material.

FiberCore Europe BV, situated on the Nieuwe Maas River, a few miles from the Port of Rotterdam in The Netherlands, has distinguished itself in the world of composite infrastructure. Established in 2008, the company has fabricated and installed more than 500 composite bridge structures, including composite bridge decks that are rated in the highest load class recognized in the European Union (EU) design codes (60,000-kg traffic load). It is also the source of the world’s largest fiber-reinforced plastic (FRP) waterway lock gates for shipping canals (see Learn More).

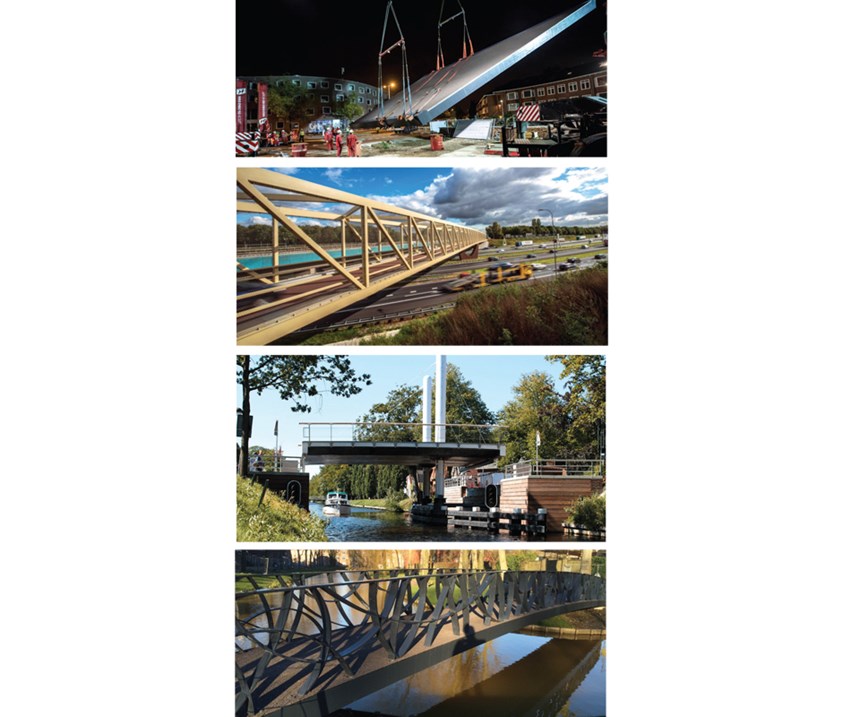

CW visited the FiberCore Europe facilities, guided by company founder Simon de Jong, who asserts, “We’ve changed the whole logistics and building process for bridges and other infrastructure.” A prime example is the oddly shaped, 18m-span Kruisvaartbrug bridge, in Utrecht, The Netherlands (Fig. 1), which features a 90-cm thick composite deck. “We put it into place in 10 minutes,” he recalls. “Everything was prefabricated, including the aggregate surface, so no extra steps were needed.”

De Jong says the same approach was used in the 142m-long hybrid composite deck/steel truss bridge that now spans the A27 motorway near Utrecht, which features two 71m spans between supports, and the previously noted 13m-tall, 6m-wide Wilhelminakanaal lock gates near Tilburg. “We try to prefabricate as much as possible,” he explains. “For the lock gates, it is not just the door panels, but also ancillary parts and attachments, in order to greatly simplify installation. It’s the light weight of our solution that enables this modularization and prefabrication.”

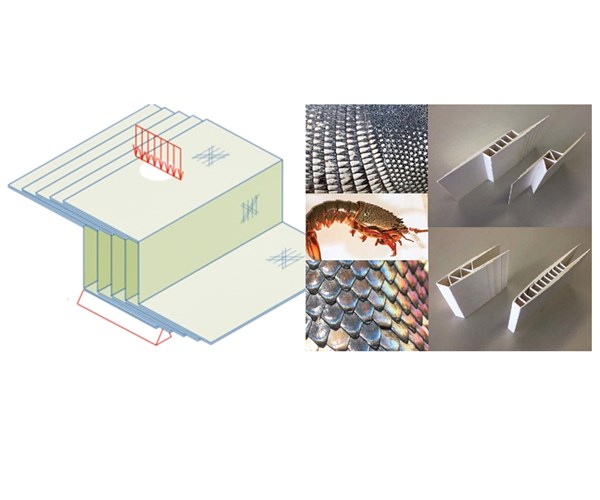

This lightweighting is possible due to composites, but the high load-bearing capabilities and long spans are a product of the company’s patented InfraCore technology (see Disruptive composite infrastructure and the Side Story below).

FiberCore Europe is now working to introduce InfraCore technology into new applications, including liquid natural gas (LNG) tanks, ships, wind blades and aerospace structures.

InfraCore inside

Examples of what InfraCore technology achieves include an all-composite vertical lift bridge in Oosterwolde, located in the Dutch province of Friesland (Fig. 1). The 11.2m-wide bridge, which spans 12m, is rated for 60-MT of traffic and integrates the counterweight for the lowering mechanism inside part of the composite bridge deck. “The designers loved this not only for the clean aesthetics,” explains de Jong, “but it is a financial benefit as well because ballast cellars are terrible for maintenance.” Eliminating ballast cellars, where counterweights sink when the bridges open, results in huge cost and time savings. Another Dutch lift bridge, built in Muiden and constructed as a single module, was so lightweight that it was easy to lift with a standard hydraulic system and no counterweight was needed. “We installed the whole lifting piece in 30 minutes,” notes de Jong, adding, “the bridge also goes up and down much faster than its heavier steel predecessor.”

In general, FiberCore Europe’s composite lift bridges are 20-30% less expensive than steel alternatives. Cost savings are also reaped in static bridges. Lightweight composite components reduce or eliminate the need for supports and modifications to existing structures. A case in point is the 17.5m long, 2.5m wide composite bridge in Ghent, Belgium, which connects two of the oldest buildings in the 17th Century city center. “There was no need for structural modifications to the buildings,” says de Jong.

Another example, and possibly the beginning of a new bridge design paradigm, is the 20m long, 1.9m wide bridge on the Excercitiesingel in Rotterdam (Fig. 1, bottom photo). It is 50% less expensive than steel because it was designed based on strength, not stiffness. Normally, design guidelines for FRP bridge structures mandate stiffness-driven designs, which can increase weight unnecessarily. “A standard InfraCore bridge designed on stiffness can be up to 10 times stronger than needed,” explains de Jong. “Due to FiberCore Europe’s significant bridge construction experience, we asked the bridge’s design engineers to allow us to build the bridge where it is still five times stronger vs. steel but not stiffness-driven.” The resulting all-composite design features an aesthetic geometric lattice railing — designed and produced by innovative FRP company Jules Dock (Rotterdam) — and a bridge thickness of only 25 cm, making it the most slender FRP bridge in the world (ratio 1:68). “After the bridge was finished in our facility, we could load it and deflect the deck approximately 1m,” he notes. That had been anticipated. “Once we installed it, anchoring each end in concrete, it was sufficiently stiff for the end-use and pedestrian/cycling loading per its rigorous design.”

Scalable, repeatable process

With that as introduction, CW’s tour begins in the administration and engineering offices at the 7,000m2 facility’s east end, where FiberCore Europe’s seven engineers, most trained in civil or mechanical engineering, work with clients, architects, government engineers and regulatory authorities to ensure composite designs meet clients’ requirements, then prepare drawings for fabrication and installation. A few are composites engineers but others have received an education in FRP since being hired.

De Jong leads the way out into the large open production space to the building’s west end. This is where polyurethane and other types of foam core are received as well as glass fiber reinforcements. The foam comes with grooves cut to aid in molding curved shapes. De Jong explains that sometimes the foam is perforated as well to aid resin flow during infusion molding. “All of that is designed-in per bridge, depending upon requirements.”

De Jong walks back east to an adjacent area where glass fabrics are unrolled and patterns are cut. FiberCore Europe uses mostly noncrimp fabrics and a smaller number of chopped fiber mats. Here, precut foam core and glass reinforcements are pre-assembled, marked and stacked in preparation for each successive project. Every material is tracked, and each pre-assembly is assigned a number with the material data attached to it (e.g., batch and lot of foam and glass, etc.).

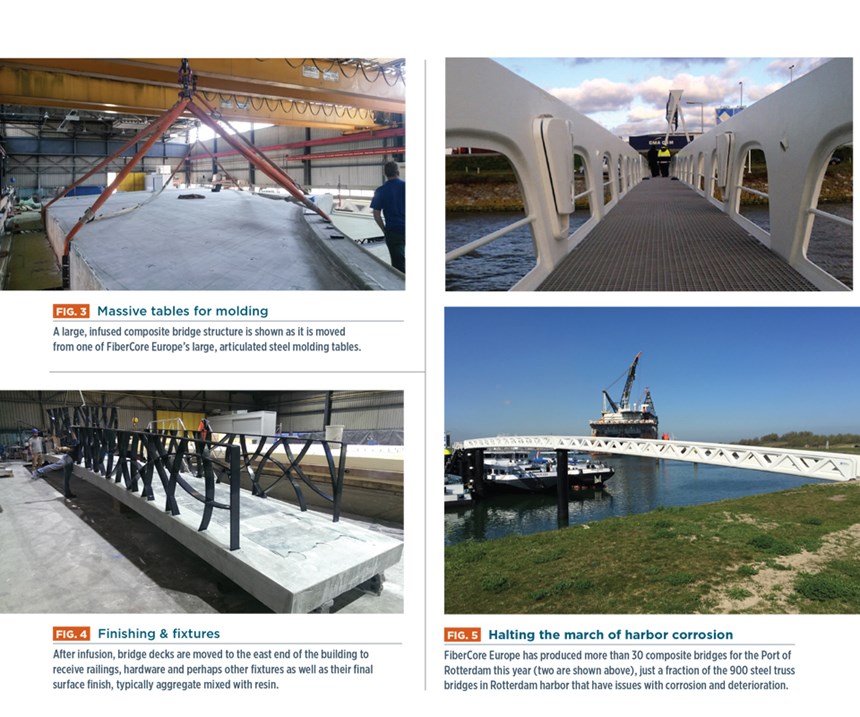

Continuing east, de Jong points out two large articulated molding tables — the longest is 55m by 6m — each comprising a steel plate on top of adjustable steel scaffolds. These can be reconfigured to mold bridge decks and support structures (Fig. 3). Mold surfaces are prepared with a release film/foil. Fabrics are then laid onto the molding tables, followed by placement of the glass-wrapped beams and then the top skin fabrics. The layup is vacuum bagged and resin is measured and mixed for infusion. Much of the resin that FiberCore Europe uses is supplied by Royal DSM (Heerlen, The Netherlands).

Returning to the building’s east end, de Jong points out two short (9m long) bridges in finishing stages. One is receiving a mix of aggregate and resin to provide its final surface (Fig. 4). “This small span we infused in one hour, but if we shoot a span 10 times that long, we still infuse it in one hour,” he says. “This is because we use a very standardized, repeatable process. We have built over 700 structures and have never had any problems with infusion,” he claims, noting that the shorter infusion time also reduces risk. “The more time during your process, the more variables and unplanned scenarios. We impregnate all of the part in one flow, at one temperature, so the process is more stable.”

Although the small bridges were to be shipped fully prefabricated, ready for installation, for larger projects FiberCore Europe also produces bridges in sections that will be shipped separately, then installed side-by-side and connected on site. During CW’s tour, eight sections were being fabricated for a 110m-span by 7m-width pedestrian bridge for the city of Amsterdam. For this project, the composite was chosen to replace degraded timber decking. The rebuilt bridge will reuse the existing primary concrete structure, which is still in good condition. “We will have the sections finished as much as possible and then complete the construction on site in Amsterdam,” de Jong explains. He notes that with its current production setup and available space, FiberCore Europe can build as many as 140 bridges per year. “Our process is very scalable and easy to replicate,” he observes, adding that the company is looking to license its technology to a series builder/partner in the US to serve the North American market.

Future of FRP bridges

There is a big discussion in Holland and Europe right now about the lifecycle analysis (LCA) of FRP, says de Jong. “Ten reports say it is better for nature, while there is a significant and strong lobby against it,” he adds, noting this is mostly from the concrete lobby because FRP is becoming strongly competitive in their markets. “However, our cofounder Jan Peeters won Engineer of the Year in 2016, recognized for his influential work in FRP infrastructure. He was nominated, in fact, by concrete and steel engineers. So I think the whole industry realizes that FRP is the future.”

Bolstering FRP’s positive outlook is the current trend to replace steel and aluminum harbor bridges or gangways with composites (Fig. 5). “Every harbor in the world has these bridges, going from the land to the docks,” says de Jong. “There are 900 steel truss harbor bridges in Rotterdam harbor, and they all have this issue of corrosion and deterioration. This year, FiberCore Europe has produced more than 30 harbor bridges for the Port of Rotterdam.”

In spans of less than 25m, however, composites still lose out to lower-cost steel. Composites win for 20-50m spans because their lower weight requires fewer support columns. In some versions, FiberCore Europe has matched the weight of the pontoon that the gangway/bridge ends upon so that it does not push the pontoon down, but allows it to move with the rise and ebb of the tides. These designs also have lights integrated into them and use a bio-based polyester resin from Polynt (Scanzorosciate, Italy) for an overall environmentally attractive solution.

FiberCore Europe has extended this bio-based concept via the bio-basalt-balsa (B3) bridge in the Schiphol Logistics Park, adjacent to Amsterdam’s Schiphol Airport. Designed to be eco-friendly and last for >100 years, this 15m-long, 2m-wide all-composite pedestrian bridge maintains the bio-polyester resin but switches out fiberglass for basalt fiber reinforcement, made from igneous rock and offering greater strength and stiffness without a major cost uptick. The bridge also features a lightweight deck of balsa-cored composite sandwich construction, and was built in cooperation with Dutch engineering firm Royal Haskoning DHV (Amersfoort, The Netherlands), basalt fiber supplier Mafic S.A. (Kells, Ireland) and balsa core supplier Airex AG (member of 3A Composites, Sins, Switzerland), with core CNC-machined by Poly Base (Tilburg, The Netherlands).

Although FiberCore Europe sees continued strong growth in composite bridges and other infrastructure, it also sees a serious threat from builders who do not use structurally sound designs and fabrication methods. “We need competitors in infrastructure to build the market,” de Jong acknowledges, “but unfortunately, some are using technology that goes back to the 1990s and, already, some of their bridges have broken.” He cites a bus bridge that broke after only two months in service. “I talked to the local government minister and explained why this happened and how he could rehabilitate the project, using FRP, but rightly. ‘We will not use FRP again for 20 years,’ was his response.” Because of such incidents, FiberCore Europe is working with Dutch bridge authorities to write new FRP guidelines for infrastructure. “The whole reason our company exists is because there were failures in the other ways that have been used to make composite bridges,” says de Jong. “We know there is a future for composites in these applications,” he adds, “but that future must be safeguarded by making sure these materials are used correctly.”

Sustainable bridge refurbishment

There may indeed be a very large future for composites in bridges, but perhaps even more so in refurbishment than original construction. FiberCore Europe is a key partner in the SUREBRIDGE project, one of nine scheduled for demonstration in 2017 as part of the Infravation Infrastructure Innovation Programme. Organized by transport ministries across Europe, Israel and the US Federal Highway Admin., Infravation’s goal is to prove out innovative solutions for road infrastructure challenges. SUREBRIDGE was awarded US$1 million to demonstrate bridge and road refurbishment. FiberCore Europe’s partners for this two-year project (October 2015-March 2018) include Chalmers University of Technology (Göteborg, Sweden) and AICE Consulting in conjunction with the University of Pisa, both located in Pisa, Italy.

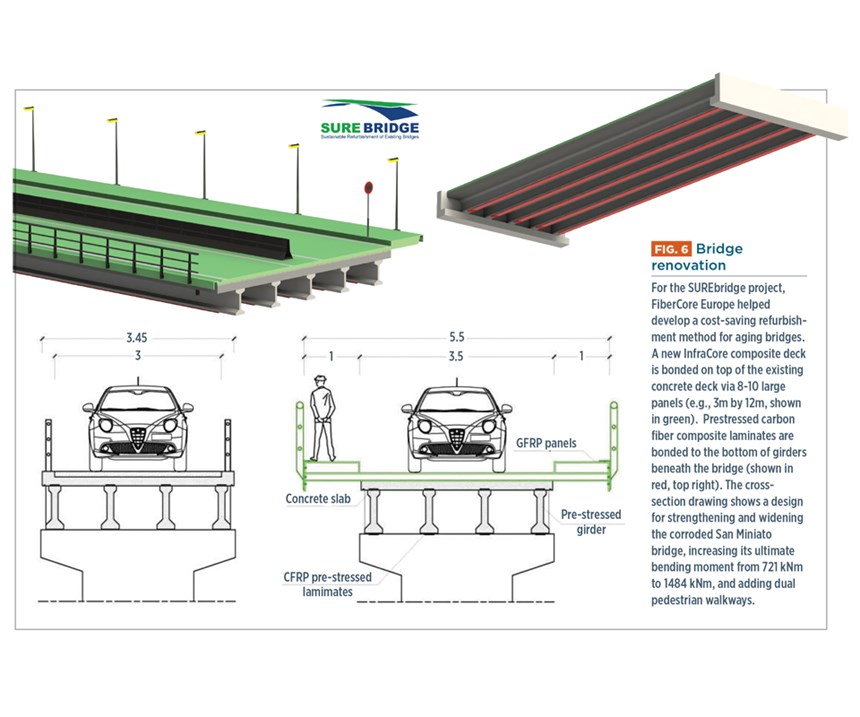

According to project coordinator Dr. Reza Haghani of Chalmers University, there are more than 1 million bridges in Europe. More than half of them have been in service for 20-100 years (the oldest are railway bridges). Many are in need of repair/refurbishment, mostly due to issues with concrete decks. Refurbishment is estimated to cost at least €50 billion. SUREBRIDGE proposes to significantly reduce this figure by combining two technologies: an InfraCore composite deck adhesively bonded to the top of the existing concrete deck, with prestressed carbon fiber composite reinforcement to provide additional support underneath (Fig. 6, above).

“The width and depth of bridge decks to be rehabbed varies, but they typically comprise a concrete deck resting on concrete girders,” explains FiberCore Europe head of engineering Martijn Veltkamp. “The deck is where the most refurb is required.” It is also where traffic disruption must be minimized by making the refurb process as short as possible. “We have already proven that our InfraCore composite decks can be prefabricated and installed quickly,” notes Veltkamp. “The design of each deck will be based on the current and future deck load requirements plus the degree of concrete deterioration.”

Some concrete decks also will require strengthening underneath and, perhaps, even wrapping with composite laminate at the bottom of the girders. Although under-deck reinforcement may use glass or carbon fiber laminates, Veltkamp says rehab to girder bottoms will use carbon fiber-reinforced polymer (CFRP) and also will be prestressed. “Chalmers University has developed a method of prestressing CFRP,” he explains. “This prestress is not applied all at once because that presents a high risk of peeling at laminate edges. Instead, it is applied gradually, over a long distance, producing a more robust construction for adhesion.” Veltkamp notes prestressed CFRP is applied to the bottom of the girders, “because this is where strengthening is most efficient.”

The technology for adhering the InfraCore composite deck on top of existing concrete is also innovative. FiberCore Europe originally proposed its method of milling longitudinal grooves into the concrete, filling these with adhesive and then lowering the composite deck with molded-in ribs that mate precisely into the grooves, achieving a mechanical lock as well as adhesive bond. “We already complete this type of installation on an industrial scale,” says Veltkamp. In 2016, a further development was completed to reduce environmental impact and worker health hazards — epoxy adhesive was replaced with high-performance mortar. Testing of prestressed, CFRP-strengthened girders was completed in 2017 at Chalmers University, showing a 150% increase in ultimate bending capacity, a reduction of crack width in the now-strengthened girders and improved durability.

The SUREBRIDGE project design case study involves a 60m long vehicle traffic bridge that comprises four spans of 15m each. It crosses the Elsa River in San Miniato, Italy. Its 3m-wide concrete deck is composed of a 160-mm thick concrete slab (cast on site) and four prefabricated, pre-stressed concrete girders 1m high and spaced 1m apart. Built in 1968, the bridge was inspected in 2006 and found to have concrete spalling, corrosion of steel rebar and breakage in some of the steel wires used for prestressing. Finite element models and analysis were completed for the original bridge and a strengthened design. The latter would feature a deck widened from 3m to 3.5m and an overall width expanded from 3.45m to 5.5m to allow for FRP pedestrian walkways on either side, next to the single vehicle-traffic lane. The SUREBRIDGE design more than doubled the bridge’s ultimate bending moment from its damaged state at 721 kNm to 1,484 kNm. Thus its benefits were demonstrated and design guidelines were developed for a representative application.

Discussion of these design guidelines and results from the full-scale testing campaign completed in 2017 were presented at a Sept. 1 workshop at Chalmers University and a Sept. 22 workshop at the University of Pisa. At both events, local road authorities expressed interest in SUREBRIDGE, yet stressed the importance of standard design guidelines to get such innovations formally accepted.

The workshops reviewed the comprehensive computer-aided design (CAD) models and standard operating procedure developed as an end-of-project deliverable. “The goal is to have a software design tool where you can fill in the bridge size and other parameters, and then analyze and evaluate the options for refurbishment, using the SUREBRIDGE solutions,” says Veltkamp. “Transport authorities have already requested pilot projects to demonstrate the SUREBRIDGE technology ... and we are working to define these projects.”

Another development with promise for the US is interest from the Army Corps of Engineers (Washington, DC, US). “They saw our lock gate projects and approached us, asking why our technology worked where others did not,” de Jong relates. “We explained the issues with other composite technologies used in the past and also what we have now developed using InfraCore. So now we are starting a relationship and hope to work together in the near future.”

Composites: Fourth major construction material

In a validation of the work that FiberCore Europe has done to prove composites’ viability as a construction material, engineer William Schutte with the City of Rotterdam Engineering Office in the May 2016 SUREBRIDGE kickoff meeting described his vision for Rotterdam’s future. It will include slender bridges without pile foundations, bio-based composite structures and composites in both floating infrastructures and normal building construction. Most importantly, he listed composites as the fourth major construction material (in addition to wood, metal and concrete), noting that hybrid solutions are typically the most optimal.

De Jong notes that since January 2017, the next applications of InfraCore have been developed through a separate entity, InfraCore Co. Ltd., also based in Rotterdam. The new company is closely connected with European research institutes and leading composites engineering firms. “We started with at least six major projects in progress,” he adds. “The applications are wide ranging, but all heavy-duty structures that you would never imagine could be built using composites, spanning ships, wind energy and the military. The acceptance of FRP in heavy construction is now a fact. What we are doing is just the beginning of a huge development.”

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreComposites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More