Proper mold care: Mandatory!

CT surveys mold care product suppliers for guidance through the critical steps of mold preparation and maintenance.

Although many of the products composites processors use in manufacturing — CAD/CAM software, machining centers, molding machines and finishing equipment — are vital to the production of high-quality parts, arguably none are more important than the mold. The tool surface sets the quality baseline for production-part quality, so the part shape and surface quality can be no better than that of the tool. This “quality tool = quality parts” equation is intuitively understood by most processors. Less well understood is the critical need to preserve that baseline via proper mold care. A well-maintained tool will hold the line on quality longer and produce a greater number of consistently acceptable parts. The irony is that many processors, when faced with tight product-delivery deadlines, see the cost and time required for mold prep as an obstacle to productivity. The negative effects of poor mold care then can accumulate slowly, becoming apparent only when it is too late for easy remedies. Cutting corners on mold prep hastens the introduction of product inconsistency, shortens the tool’s useful life and can lead to costly and time-consuming postmold rework of the finished product. Apparent gains in production speed are offset by the cost of remedial action.

The mold care industry is flush with products designed to help processors easily meet every tool maintenance need. Mold care products can be classed, generally, in five categories: mold compounds, mold sealers, mold releases, mold polishes and mold cleaners. These products, however, are most effective when used properly, and for some processors, that’s easier said than done.

External releases

The fastest-evolving product is external mold release, which is applied to the mold surface to prevent contact or adhesion between the mold and the part. Releases for traditional composites molding (open and closed molds) were originally provided in paste wax form. Waxes require application after each cycle and thus earned the label “sacrificial” because the wax is consumed by each part that is molded. Ray Lukich, sales manager at TR Industries (South Gate, Calif.), a supplier of paste wax and the Multi-Pull line of semipermanent releases, says that some waxes can last up to three cycles, depending on resin and part complexity, but he notes that the disadvantage remains: Wax takes time and effort to apply.

The labor-intensive wax systems prompted demand for release systems with longer useful lives. The answer, which has been around for more than 50 years, is the semipermanent mold release, which usually has a solvent-based carrier and provides effective release for multiple cycles — with the number of cycles depending on the resin, fiber and tooling material used. The number of releases per application ranges from a few to hundreds.

Semipermanent releases are attractive to high-volume molders because they require less frequent re-application and they cure relatively quickly. The function of a semipermanent depends primarily on a polymer that crosslinks and bonds with its substrate, which typically is a mold sealer.

The problem with semipermanents, however, is the solvent carrier. Many processors are trying to move away from solvents on the shop floor, thus mold care suppliers have worked for the last few years to develop water-based semipermanent mold releases. Peter Heidecker, Asia-Pacific manager for Zyvax (Ellijay, Ga.), which makes the EnviroShield, FiberglassShield, WaterShield and Flex-Z releases, says the move away from volatile organic compounds (VOCs) is pronounced. “This is being driven in some countries by concern for the workers’ safety or government regulations,” he says. “In other cases, the cost of transportation of volatile/hazardous materials is becoming increasingly expensive.”

The use of water-based releases also offers the opportunity to eliminate the expense of hazardous waste removal.

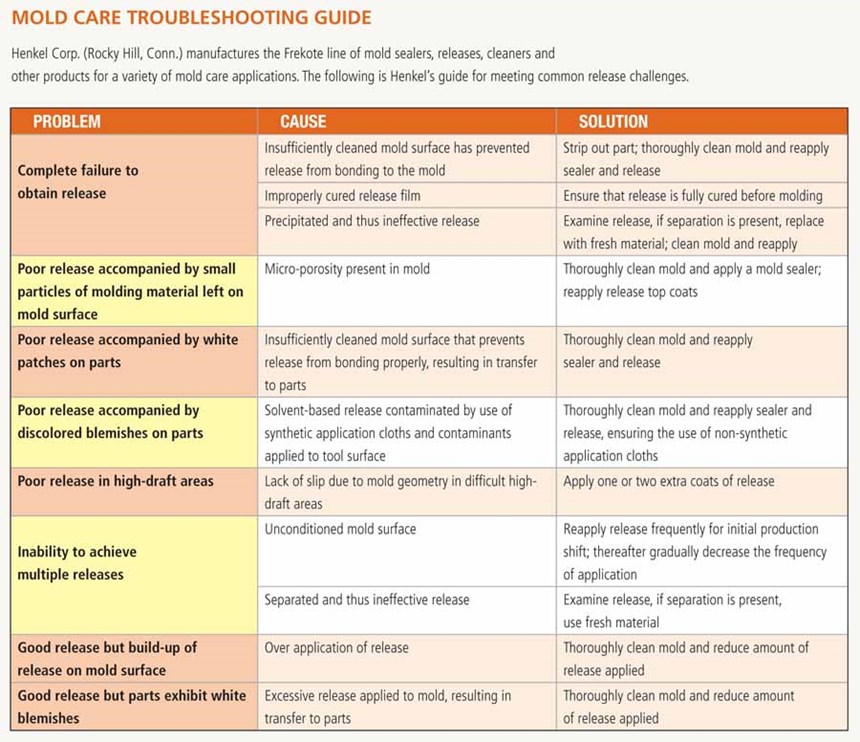

Loren Nauss, technology manager, maintenance chemicals, at Henkel Corp. (Rocky Hill, Conn.), which manufactures the Frekote line of mold-care products, notes increasing demand from governments and customers to get VOCs out of the workplace. “The VOC and HAP [hazardous air pollutant] content of all materials used in the composites manufacturing process, even process aids such as release agents, is an ongoing concern for processors,” Nauss says. This is due, in large part, to the trend toward increased regulation, such as the Maximum Achievable Control Technology (MACT) standard for composite manufacturing in the U.S. “This trend has required mold care product manufacturers to investigate alternative solvents and to develop water-based cleaners, sealers and release agents,” says Nauss.

But water-based releases initially presented challenges. They took longer to cure than solvent-based systems (water takes longer to evaporate) and didn’t release for as many cycles as solvent-based systems. Still, the desire to get VOCs out of the manufacturing environment is real, and mold care product manufacturers have worked intensively to develop water-based releases that are a viable replacement for solvent-based systems. Although water-based releases are readily available from many suppliers, the outlook, apparently, is mixed.

Zyvax has been active in the water-based segment with its EnviroShield product and reports cure and release capabilities on par with solvent-based products — 15 minutes between coats and 30 minutes before molding vs. 15 minutes for both steps with its solvent-based Flex-Z. “I am very pleased that 70 percent of our worldwide sales came from our environmentally friendly products in 2010,” says Tannis Layman, North American sales manager at Zyvax.

Other suppliers report that water-based releases are still establishing themselves in the release market. Nancy Teufel, product manager at mold care products manufacturer AXEL Plastics Research Labs Inc. (Woodside, N.Y.), which makes Xtend and MoldWiz solvent- and water-based releases, says, “There’s more lip service paid to water-based releases than actual conversion. It will grow, but in high-volume markets, patience is not there.”

Mark Finn, VP of sales and marketing at McLube (Aston, Pa.), which makes the MAC line of solvent- and water-based releases, says water-based systems are in demand, but they are not always feasible. “The majority of our customers would prefer to use a green technology product,” he claims. Where possible, he says, “We work closely with composite molders to assist them in converting from solvent-based materials to our water-based products.” However, a customer’s current process, production demands or the cost associated with modifying their process can make the move impractical or cost-prohibitive.

Still, it’s clear that the safety offered by water-based systems means that they are here to stay and likely will continue to evolve as a mold-release standard for composites processors.

New mold prep

The development of a new composite part or structure can be time-consuming. When a mold is finished, the rush to produce parts, turn a profit and meet a deadline is understandable. But a mold whose surface is not properly prepped for production is not yet a production mold. The time and effort required for proper mold prep pays for itself in longer tool life and higher-quality parts.

One immediate consideration is that proper mold prep begins before one uses mold care products. How much time should be spent perfecting a master mold or plug vs. a production tool? Experts contacted for this article suggest that any time spent repairing and fine-tuning a master or plug is money and effort well spent. “It’s better to have a perfect plug, which allows you to minimize part rework,” says Robert Renshaw, managing director at REXCO (Conyers, Ga.), which makes the PARTALL and FORMULA FIVE lines of releases. “Do all your repairs and sanding on the plug, not the production mold. As soon as you begin sanding the mold, that’s the beginning of the end of the mold.”

How a mold is prepped, say the experts, depends on several variables, including the molding process, tooling materials, the tool’s geometry, process temperatures, cycle time, part size, desired part surface quality and others. Most mold-care product suppliers provide questionnaires or work sheets to help guide customers through the product selection process to help optimize release performance.

When it comes to open and closed mold systems, a composite tool with an outer layer of tooling gel coat is common, but sometimes it is difficult to prep and maintain, says McLube’s Finn. “Nonmetallic molds are some of the more challenging surfaces to care for,” Finn reports. “They can be difficult to wet, thus causing a good mold release product to not perform properly. That is why it is necessary to work closely with production to determine specific release issues.”

Metallic tools can be sealed and prepped for release, but they tend to be more porous and have different temperature requirements. In any case, the mold prep process has a few basic guidelines, depending on the type of release.

Cleanliness is paramount. Every supplier contacted for this story states first and foremost the importance of a clean mold surface before applying sealer, release or any other mold care product. “Our major concern is that the workplace maintains a clean environment,” says McLube’s Finn. “This applies to clean molds, clean tools and clean release coating applications. It is important for manufacturers to understand that no release coating will allow a dirty mold to perform effectively.”

Henkel’s Nauss recommends, “Ensure that the mold is properly cleaned prior to applying mold sealers and mold release agents. Improper cleaner will result in poor performance of the products. Also, be careful not to overapply the mold release agent. This will cause buildup on the mold and result in discoloration and poor performance.”

A clean surface is one free of dust, sealer, release, polymer or other contaminant. Cleaning should be done with a clean, lint-free, all-cotton cloth. Some suppliers also recommend a high-quality paper towel. Mold cleaner shouldn’t be mixed with other cleaners or mold care products. All mold care products should be stored in sealed containers at ambient temperature.

Semipermanent release. The first step in semipermanent mold prep, which is optional, is the application of a polish to bring the mold surface up to a smooth, even finish. This is followed by mandatory application of mold sealer — sometimes referred to as interfacial coating. The required number of mold sealer coats varies by mold and release type, but it can range from one to several. This step is critical because the sealer fills small gaps, pits and any other irregularities in the mold, thus providing a smooth surface to which the mold release can adhere. Further, a mold with release but no sealer can develop microcracks. Win Doolittle, business director at Specialty Products (Corona, Calif.), maker of the KantStik line of solvent- and water-based releases, notes that a sealer forms a barrier between the tool surface and molding materials and prevents styrene from migrating from the composite part onto the tool surface, where it can cause hard-to-clean hazing.

In addition, Zyvax’s Heidecker says, “Proper sealing will assist with improved release, give the mold longer life and usage of mold release can be reduced.” Too many molders, he notes, fall prey to the “more is better” maxim. “There is certainly a perception that applying more release will avoid the need to seal molds.”

The temptation is great to take shortcuts and avoid using a sealer altogether, says Axel’s Teufel. “Customers think sealer and release are the same, so they add extra release and no sealer.” And even when sealer is used, many suppliers say the more important concern is to allow enough time for thorough curing between coats. Drying is not curing, says Teufel, noting that fewer cured coats are better than many uncured coats.

After the sealer is fully cured, the next step is to apply the mold release. It is usually wiped on, and, like the sealer, one or more coats may be required, depending on the tool geometry. Again, especially with semipermanent releases, time must be allowed for complete cure between coats. A solvent-based release can take 10 to 30 minutes to cure — the longer the better.

During molding, operators will be required to reapply release to maintain the desired release properties. How many releases can be achieved varies greatly from application to application. “Many customers ask, ‘How many releases can I get from this product?’” says Henkel’s Nauss. “This is one of the largest misunderstandings with semipermanent mold-release agents. Every application needs to be qualified before use in production. Part materials, temperature, geometry, to name a few, are important factors to keep in mind when selecting the proper mold release.”

Wax release. The use of a wax release requires minor changes in procedure. First, the mold must be sanded using sandpaper of progressively finer grit. TR’s Lukich says to progress to paper with 600 to as fine as 1,200 grit. Specialty Products’ Doolittle says going as fine as 2,000 grit might be warranted, depending on the desired gloss. This is followed by application of a tooling compound to remove the fine scratches left by the fine grit. Doolittle says to use a minimum 2,400-rpm buffer for compound application and to expect a coverage rate of 1 ft2 every 20 seconds. After compounding, two coats of sealer should be applied and hand buffed to a high gloss. The wax release follows, also hand applied and hand buffed. Doolittle says six coats of paste wax is not uncommon, with 20 minutes to an hour between each coat for cure and overnight cure following the final coat.

Tape test. The final step in the mold prep process, whether the release is semipermanent or wax, is the use of a high-quality masking tape to test randomly selected mold surface locations to verify complete coverage of sealer, mold release and polish. Tape is applied then peeled off the surface. The peel resistance should be substantially lower than seen on an unprepped mold. Areas where peel resistance is significant should be resealed, followed by an application of mold release.

Taken together, cleaning, polish, sealer and release application can consume an entire work shift. Although this strikes some as excessive, mold prep should be viewed as the final, crucial step in the mold manufacturing process. When it becomes a habit, rather than an exception, the resulting tool should produce the best possible parts and structures. Release cure can be accelerated by use of an oven, or, suggests Renshaw, operators can condition multiple molds simultaneously to maximize efficiency.

Drew Martin, technical sales representative at Zyvax, reports that the causes of many customer complaints about product performance can be traced back to improper product use: “That is why we evaluate the customer’s processes, mold conditions [and] current procedures and make suggestions to improve their overall performance. Generally we find the most common areas of improvement are with the product selection and application.”

Mold maintenance

Using the correct products, however, is only half the battle. Each person contacted for this story noted that the most effective, efficient and well-run composite shops they’d seen all had one thing in common: A defined, structured, measured mold maintenance plan for regular removal of molds from production for cleaning, reconditioning, recoating with sealer and release, and repolishing.

A schedule is kept for each mold, ensuring that it is pulled from production after a predetermined number of cycles. Pulling is timed to prevent problems (e.g., sticking parts, hazing, cracking) rather than respond to them. This requires some trial and error to determine when a particular part or mold starts to develop signs of sticking and hazing. “A lot of shops end up dealing with problems after the fact, after hazing has developed, when it’s harder to clean the tool,” says Lukich. Doolittle concurs: “It is smarter to put effort into fixing mold issues rather than part work-arounds.”

Given its importance, mold maintenance in some shops is entrusted only to well-seasoned employees who are fully trained for the work. “Too often, mold cleaning and maintenance is handed over to the last person hired,” says Teufel. Zyvax’s Heidecker says, “Generally the least trained operator will be the person responsible for mold care/maintenance.” He recommends that an experienced employee who understands the importance of mold care should bear that responsibility.

Michael Mapes, a Zyvax technical sales rep, suggests the following progressive mold maintenance plan:

Prevention: Every time a part is pulled and put back into production

Inspection: Every X number of cycles or every X number of days

Minor maintenance: Apply a coat of release every X number of cycles

Major maintenance: Every X number of cycles, strip the tool, clean it and reapply sealer and release

As a starting point, molders could develop a simple paper-based mold-tracking system that documents basic parameters: mold number, number of parts and pulls, cleaning cycle date, sealer used, number of sealer coats, date of sealer application, release used, number of release coats and date of release application.

Teufel notes that when using a closed mold, the mold’s B side might ultimately determine the cleaning schedule. “The B side is usually less finished and more porous, thus parts tend to stick here first.” She also says to watch the resin because more aggressive polymers can attack the mold surface sooner than less aggressive materials. Finally, she recommends periodic checks for chronic scuff marks on finished parts. Scuffing indicates the area of the part that will wear most quickly, either because of the angle at which the part is removed or because of acute angles in tool geometry that bind the part. These areas determine the maintenance schedule.

After a mold is reconditioned, tape peel tests should be repeated. If any part of the tool was repaired with a patching matte, Teufel says to apply extra sealer and release in that area because mattes tend to be unusually porous.

Mold prep and mold maintenance plans present not only a technical challenge, but a cultural challenge as well. Several interviewees noted that it’s not unusual for a shop to have ingrained poor mold-care habits, with employees who believe their knowledge of mold care products and processes is unassailable. “The habits that some shops have are very hard to control and change,” says TR’s Lukich. “They tend to gravitate back to the same old habits.” Rexco’s Renshaw notes that “good record keeping is what separates a sophisticated shop from a less robust operation.”

Related Content

Proper application of semi-permanent mold release systems

Performing regular maintenance of the layup tool for successful sealing and release is required to reduce the risk of part adherence.

Read MoreJamco America partners with Airtech for 3DP tool recycling

Aerospace manufacturer joins forces with composite materials company to achieve sustainable manufacturing practices that overcome traditional composite layup tooling.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreMetal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More