PRSEUS preform for pressurized cabin walls

Over the next few years, NASA and The Boeing Co. (Chicago, Ill.) will build larger and more elaborate pressurized passenger cabin structures for future blended-wing airliners.

Evaluating composites technology in 2011 for implementation on aircraft in 2025 might sound like excessive planning, but when you’re aiming for a revolution in carbon-fiber architecture and application, it’s never too soon to get to work. In fact, such long-term thinking is the status quo at NASA’s Environmentally Responsible Aviation (ERA) Project (Hampton, Va.), where engineers are looking for ways to build large transport aircraft more cost-effectively yet make them more efficient to fly.

Dawn Jegley and others at NASA’s ERA anticipate that current commercial aircraft design — tubular fuselage with attached wings — could be replaced by more efficient shapes for many applications. A senior aerospace engineer at NASA’s ERA and a 28-year veteran of composites use in aerospace applications, Jegley is working with Boeing Research & Technology (Huntington Beach, Calif.) to optimize carbon fiber composites in a hybrid aircraft wing/fuselage structure. Her research team anticipates that what is often called a “blended wing” design may represent the future of aircraft design and architecture.

Blended wing structures aren’t new; several newsworthy designs have been put forward in the unmanned aerial vehicle (UAV) arena. Boeing’s own X-48B development aircraft, for example, features a fuselage fully integrated and blended with the wings.

In a passenger aircraft, however, a hybrid wing/fuselage presents a challenge that UAV designers don’t face. Blended wing structures dictate the use of a more box-like cabin, with flatter walls and a variety of hard angles that are not found in a conventional barrel-shaped fuselage. “A hybrid wing structure has a flatter center section and has less drag, but it does not like to be pressurized,” says Jegley.

Flat-walled structures, by nature, are subject to greater bending stresses, making them less structurally efficient. “A cylinder,” says Jegley, “naturally holds pressure well.”

If the future of aircraft design depends on a hybrid wing, fatigue-sensitive metals are no longer viable cabin materials. Jegley’s team is working with Boeing Research & Technology on a multiyear effort to design, manufacture and test a composite structural concept that not only meets the mechanical requirements of a hybrid-wing aircraft, but in the process, it will allow aircraft manufacturers to greatly reduce the use of fasteners and rivets that are common in current-generation aircraft composite structures.

Partially funded and developed by the U.S. Air Force, NASA and Boeing, the new concept involves the maturation of a stitched skin, stringer-and-frame carbon fiber preform design that will form the fuselage wall of a hybrid-wing aircraft.

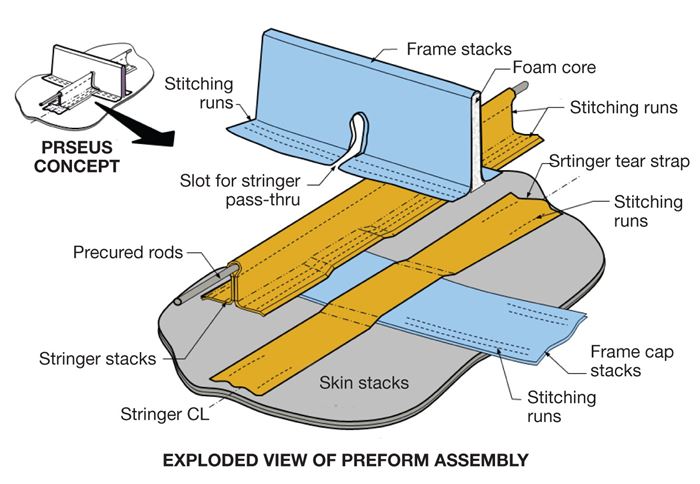

Called PRSEUS (pultruded rod, stitched, efficient, unitized structure), the wall section is a complex preform with five integrated components cut and assembled from a basic stacked fabric preform made with Hexcel’s (Stamford, Conn.) AS4 carbon fiber (see exploded view, above right). The stack features nine plies of 0.052-inch/1.3-mm-thick warp-knitted fabric assembled by Saertex USA (Huntersville, N.C.) from unidirectional AS4 tapes layered multiaxially in a ±45°/0°/0°/90°/0°/0°/±45° pattern and then loosely stitched together with Vectran liquid crystal polymer spun-fiber thread (Kuraray America Inc., Houston, Texas). The preform’s five components (in order of assembly) are as follows:

- Skin stack — The skin stack forms the wall’s flat surface structure.

- Frame cap stack — This stack is stitched in strips over the skin to provide a foundation for the frame stack (described later).

- Stringer CL — The stringer stack rests on this single-stack layer.

- Stringer stack — Boeing takes some of the AS4 stack material and wraps it around a pultruded carbon fiber rod. This rod-stiffened beam structure becomes the stringer, which Boeing stitches perpendicularly to the AS4 stack skin.

- Frame stack — The cored beam structure crosses the stringers perpendicularly. Here, the nine-ply multiaxial material is wrapped over an Evonik Foams (Magnolia, Ark.) ROHACELL foam core and notched, allowing it to nest atop the rod-stiffened stringer. The frame stack is stitched to the frame cap stack.

Alex Velicki, structures lead engineer for Boeing’s blended wing body (BWB) advanced research and technology work, says the stitching technology Boeing uses first came out of the former East Germany following the collapse of the Soviet Union. This unique, one-sided robotic stitching method is facilitated by a robotic arm end-effector manufactured by KSL Keilmann Sondermaschinenbau GmbH (Lorsch, Germany). The method uses two needles: one enters the fabric perpendicularly and the other enters at a 45° angle, both from the exterior surface of the part. This technology eliminates the use of the bobbin element found in traditional sewing systems and vastly simplifies the preform assembly tooling. The final stitched dry fabric preform, Velicki notes, is stiff enough to support itself, which eliminates the need for rigid interior mold-line tooling to shape the part features.

BWB-related work so far has focused on molding increasingly complex flat integrated panels, which Boeing does via its Controlled Atmospheric Resin Infusion (CAPRI) process, a proprietary form of vacuum-assisted resin transfer molding (VARTM). The molding is done on a single-sided metal tool, and the whole structure is bagged and infused with Hexcel’s HexFlow VRM34 out-of-autoclave epoxy. Velicki says the patented CAPRI process uses a distributed vacuum methodology to maintain positive bag pressure on the preform during infusion, resulting in higher fiber volumes in the finished structure than could be achieved using conventional resin infusion schemes. After processing, finished test articles are either sent to NASA for testing or remain in California for testing by Boeing.

Although NASA and Boeing have so far primarily worked with a nine-ply stack arrangement (0.052-inch thickness per stack), Jegley says a hybrid wing craft would, conceivably, use multiple stacks or building blocks, depending on the mechanical needs of the application. Where the wing blends into the fuselage, for example, could require as many as 15 stacks (15 stacks x 9 plies) to provide the required strength and stiffness and then taper down to just a few stacks at the wing’s tip.

NASA has tested one pressurized panel to date (in addition, three large subcomponent panels and numerous small specimens have been tested with in-plane loading). Reportedly, the results are promising. To start, Jegley says the panel was pressurized to 18.4 psi/1.27 bar, which is the minimum required for aerospace testing. No damage was detected, so the panel was subjected to minor impact and pressurized to 18.4 psi again. Still, no damage was detected. It was then pressurized to 28 psi/1.93 bar, at which point a pultruded rod failed, but damage growth was arrested by the stringer stitching prior to reaching the skin. No loss of pressure was recorded, so the panel suffered a noncatastrophic failure, with the skin undamaged and fully intact. The pressure was then increased to 30 psi without any measurable effects.

Other tests, Jegley reports, show that cracks propagated by impact damage on the skin travel up to and then parallel to the stitching. “The skin resists delamination on impact,” she explains. “Damage will only spread as far as that stitch row. This confines the scope of damage.”

Velicki echoes this observation, noting that damage propagation can be actively managed by the stitch row placement within the PRSEUS architecture to stop damage progression, turn cracks 90°, then ultimately redistribute internal loading to the undamaged regions of the panel — in much the same manner as metal structures operate.

“So far, the test results are exceeding our expectations,” he adds. “Absolute numbers are higher than the targets established for the BWB airframe. But what is more surprising is the gain in structural efficiency that is possible by using stitching to suppress common interlaminar failure modes rather than by adding fasteners, as is currently done.”

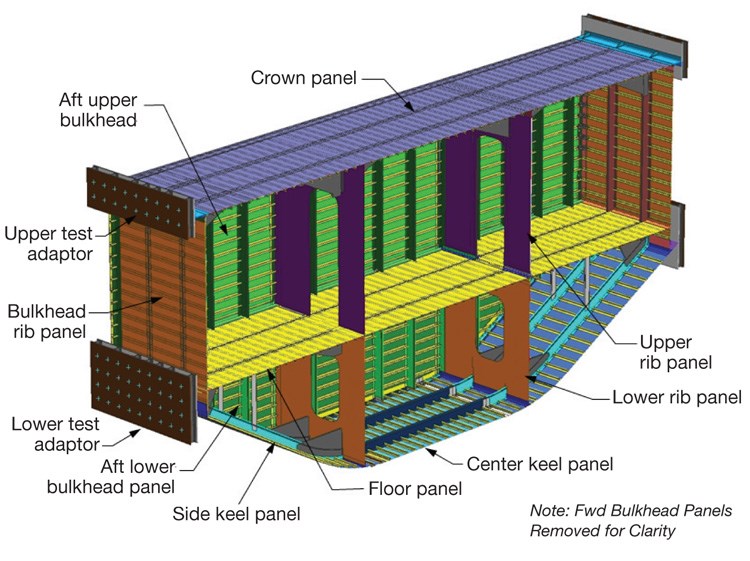

Over the next few years, NASA and Boeing will build larger and more elaborate structures. By 2013, they hope to build and test a 30-ft/9.1m center cross-section of a hybrid wing vehicle (see bottom image, at right), subjecting it to combined pressure and bending loads. That will be followed by a wing structure test and then construction of a single-pilot flight vehicle. Jegley says NASA also will assess nondestructive impact testing and health-monitoring technologies.

One thing NASA is not expected to do is measure the efficiency of the infusion manufacturing technology required to build these stitched structures. If this technology is to make the leap to large transport aircraft, it will require a cost-effective manufacturing process that can meet the production speeds of the aerostructures industry. That, says Jegley, will be up to Boeing and other adopters to iron out. Jegley emphasizes that the data and results associated with the PRSEUS structural concept are not proprietary to NASA or Boeing; the project is designed to benefit the entire aerospace community.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Blended Wing UAV

Unique unmanned craft's robust composite design a plus for rough duty.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More