THOR project develops mass-producible CFRTP hydrogen tanks

The three-year project, concluded in 2022 and aided by partners spanning the entire hydrogen storage supply chain, tested and produced 15 thermoplastic tanks, with the goal of achieving broader market introduction.

Share

Read Next

Photo Credit: Cetim, THOR project

Cetim (Senlis, France), the French technical center for mechanical industries, took part in THOR (Thermoplastic Hydrogen tanks Optimised and Recyclable), a European project for the production of thermoplastic composite tanks for hydrogen vehicles, in partnership with Faurecia, Air Liquide, Rina Consulting – CSM SpA, Sirris, the Norwegian University of Science and Technology (NTNU) and CNRS Prime.

This project was initiated in 2019 to address environmental challenges in the transportation industry. THOR, concluded at the end of 2022, sought to develop a cost-effective, high-pressure demonstrator vessel that could be mass-produced for hydrogen storage, both for vehicles and for transportation applications, that could also be environmentally friendly (i.e., recycled). This, in addition to technical requirements associated with safety and expected performance, some limitations that often make it difficult for Type IV tanks to achieve broader market introduction.

The project brought on board project partners covering the entire hydrogen storage supply chain, from technology developers through to the industrial manufacturer in addition to the end user:

- Cetim contributed its technical skills to the project, especially in relation to the material aspects — development of the material/product/process chain, characterization of tapes, implementation of specific tools, etc. — design, manufacture and recyclability of the tanks;

- Faurecia participated in the industrialization of the composite overwrapped pressure vessel (COPV) and tank design.

- Air Liquide led the safety assessment of the tanks and the validation of their operational performance;

- CSM SpA contributed to vessel validation against the standard regulation and to validation of safety improvement. In addition, CSM aided in the technology’s dissemination;

- Sirris worked on the development of numerical models and optimization of winding patterns. The aim was to predict burst/leak pressures. Tasks involve the definition of the material model, numerical validation of experimental tests on sphere/tube/dome scale and subsequently a prediction of burst pressure of the vessels with optimized winding patterns;

- NTNU monitored the integrity of the pressure vessels with respect to local fire and impact damage;

- The CNRS brought its expertise in the field of thermomechanical material characterization and damage observation. Experiments aimed to feed damage models and finite element (FE) simulations, which enable a forecast of the strength of complex structures subjected to a mechanical load and heat flux.

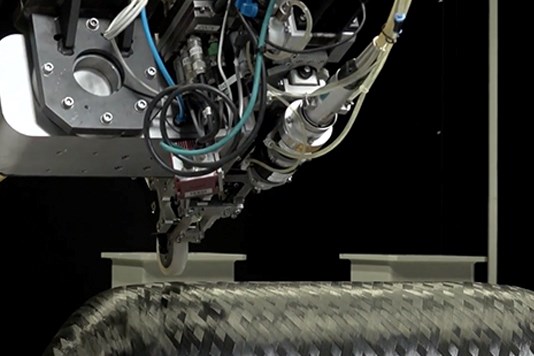

Between 2019 and 2022, 15 thermoplastic tanks were produced in cooperation with AFPT (Doerth, Germany), including two reference tanks that withstood burst pressures of approximately 1,500 bar. Following these first conclusive tests in THOR, Cetim invested in a new machine optimized for the manufacture of thermoplastic tanks. Expected delivery was early 2023.

Various members of the THOR consortium met for the closing of the project in September 2022. The video above takes a look back at some of the project’s defining moments.

This project received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking (now Clean Hydrogen Partnership) under grant agreement number No. 826262 of the European Union’s Horizon 2020 research and innovation program.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.