Reusable vacuum bags go digital

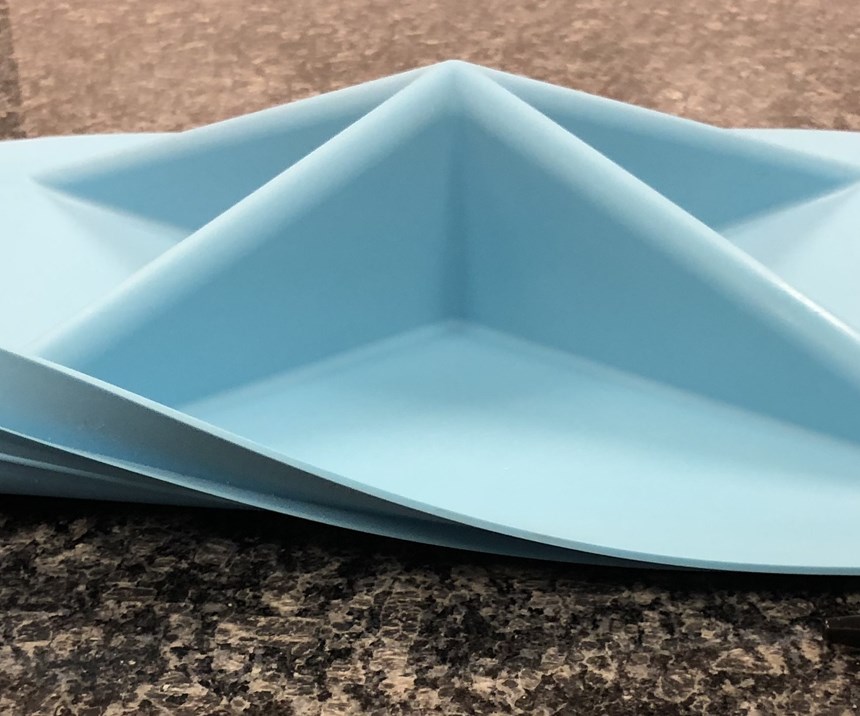

CAD-guided casting boosts precision, utility of reusable vacuum bags.

“A lot of our ideas about how vacuum bags work come from our own experience,” says Max Caprez, technical sales manager at Industrial Technologies (Akron, Ohio, U.S.), as he recounts the company’s history. Starting out more than 20 years ago as a fabricator of composite tools, Industrial Technologies experienced firsthand the challenges of maintaining vacuum integrity across a component, as well as consistency from component to component, in both autoclave and resin infusion applications. As it developed solutions that helped to reduce material costs, labor costs and fabrication time associated with vacuum bagging, the company also leveraged its reusable vacuum bag (RVB) technology to market RVB products to other composites fabricators.

Today at Industrial Technologies’ 25,000-square-foot facility, the company produces silicone reusable vacuum bags, as well as cauls, intensifiers and mandrels, as one of its main product lines. The majority of the company’s customers come from composites fabrication and maintenance, repair and overhaul (MRO) operations for the aerospace industry. Industrial Technologies continues to make RVB products from conventional silicone materials — semi-cured and cured silicone sheet — but has also advanced RVB technology to a patent-pending cast vacuum bag system. CW sat down with Caprez to learn more about the company’s cast bags and to glean some advice for composites fabricators as they work with various vacuum bag systems.

CAD-guided manufacturing

Aside from Industrial Technologies’ cast vacuum bagging, most reusable vacuum bags are produced using one of two hand-fabrication techniques. The first involves seaming of silicone sheet stock. The second, and more common, method is to use a dedicated spray machine, which creates a silicone film directly on the mold or, in some cases, on a dummy part in the mold, depending on the required fit. Multiple layers are built up to the desired RVB thickness, typically 1 to 10 millimeters. Although each RVB maker has its own silicone formulations, processing parameters and performance characteristics, RVBs generally are successfully providing composites fabricators with a means for a cleaner, more cost-effective molding of production parts, with a return on investment achieved in as few as 10 molding cycles.

Caprez asserts that conventional RVBs are sufficient for a significant number of Industrial Technologies customers. But not long ago, the Industrial Technologies team also recognized that a new approach would be needed to better meet the needs of some customers. The notion of using cast manufacturing arose, Caprez recalls, as the company serviced the needs of the MRO industry. “We were making precision cast parts out of silicone and urethane for MRO applications, and we identified a need for a reusable bag made just as precisely, designed on a computer,” Caprez says.

To produce cast RVBs for a customer, Industrial Technologies first taps its engineering team, which develops the RVB CAD model in-house or in collaboration with the customer’s design engineers. With computer modeling, the team is able to design offsets into the RVB so that the vacuum bag fits closely over the layup, and the vacuum seal is generated by these bag systems without an external frame. “It lays down right where it needs to be,” Caprez says. Compared to cast RVBs, says Caprez, conventional RVBs made from silicone sheets leave a larger gap between the part surface and the bag. “The pull-down to the surface places a lot more stress on the silicone,” Caprez notes, “and you don’t get the best properties.”

Applying the CAD model, a closed-cavity mold in which the RVB will be cast is CNC machined. With closed-cavity molding, casted RVBs can be produced not only with precise offsets but also with varying thickness, so that the consolidation force generated by the bag can be tailored to the layup of the specific component. Unlike conventionally produced RVBs, cast RVBs can be made with virtually any thickness, and Industrial Technologies has produced cast RVBs as thick as 40 millimeters. The size range of cast RVBs is also noteworthy; Industrial Technologies has cast small parts measured in grams and large parts weighing as much as 500 pounds.

Once the mold for the RVB is built, Industrial Technologies is able to quickly manufacture the needed bags, filling new orders with a 24-hour turnaround. To make each bag, the proper amount of silicone is cast (poured) into the mold, where chemical cure takes place. Casting into a closed-cavity mold enables the company to produce bags that closely fit complex shapes and undercuts much more easily and effectively than hand-manufactured conventional RVBs.

“Everything is very precise,” Caprez declares, “to the point where there can initially be over-consolidation of the component with our product.” He explains that the more precise offsets provided by the cast RVBs results in greater force generated on the component. “This shows how much more performance you can get from designing something to the right offset and thickness,” he concludes.

The when and how of RVBs

Caprez acknowledges that some composites fabrication projects are not well suited to any RVBs, while others are best serviced by conventional RVBs. “Big parts with low production volumes are not a good fit for our system,” he says. The cast manufacturing method makes it simple to manufacture more RVBs, so larger programs that need multiple bags experience a significant cost savings with cast RVBs compared to conventional RVBs. In fact, Caprez says, even the initial cost of the first cast RVB for a project typically is comparable — and often is less (by as much as 75 percent) — than conventional RVBs.

Most customers of Industrial Technologies’ cast vacuum bag system are making a high volume of parts — up to 100,000 annually. Medium-volume applications, primarily in aerospace, may use cast RVBs when the component would be time-consuming to bag with conventional RVBs or disposable systems. The form-fitted geometry of the cast bag means it can be positioned more quickly and easily. The cast system also makes sense for a lower-volume part when it is relatively expensive and requires the precision offered by cast RVBs. Caprez explains, “If the part has large material costs or labor costs, then they want the safest and lowest risk cure operation possible. They get that from our casted system.”

What should fabricators be prepared for when they are applying an RVB for the first time to a particular component? Caprez reports that the most common issues have to do with the overall assembly. In autoclave operations, for example, fabricators sometimes need to make adjustments to the vacuum monitoring equipment that goes inside the bag.

The primary point of focus when installing a vacuum bag system is, of course, vacuum integrity, and Industrial Technologies prides itself on its expertise in finding and eliminating leaks. “When you’re bagging,” Caprez emphasizes, “the surface where the bagging system is sealing off is critical.” This is where the reusable bag should have no scratches or mars that would compromise the seal. Caprez notes that, in general, operators must be trained to handle RVBs with appropriate care — though the RVB is relatively sturdy, scratches (which can be easily overlooked) can render the bag less effective.

Addressing the issues of RVB implementation returns Industrial Technologies to its roots as a composite tool manufacturer. The company continues to draw on its past experience, Caprez says, even as it continues to advance RVB technology for a growing number of composites applications.

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreSmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More