SAMPE 2017: Highlights

SAMPE returned to Seattle, WA, US, May 22-25 and featured the usual mix of conference presentations and exhibit hall activity. CW was there and offers this summary of highlights from the event.

SAMPE returned to Seattle, WA, US, May 22-25 and featured the usual mix of conference presentations and exhibit hall activity. CW was there and offers this summary of highlights from the event.

Keynote address

SAMPE 2017 kicked off officially on Tuesday morning with a keynote presentation by Rob Myerson, president of Blue Origin (Kent, WA, US), which is building a line of re-usable rockets to take people and material into space. Blue Origin’s first rocket is New Shepard, which, eventually, will be used to offer flights to carry up to six people to 100 km above the Earth for about 4 minutes of weightless flight, before returning to Earth via parachute landing. The BE-4 main rocket propelling New Shepard will be ejected after initial burn and return to a pre-designated landing site so that it can be re-used.

Myerson also discussed the forthcoming New Glenn, a larger rocket propelled by seven BE-4 engines and currently in development. New Glenn will be used to deliver satellites and other payloads to Earth orbit and is expected to be launched for the first time in 2020. New Glenn’s first stage rocket body will be recoverable and reusable as well, with landing expected to be done on a floating platform.

Composites, not surprisingly, are used substantially on the New Shepard to make fairings and panels, and likely will see more application on the New Glenn. To that end, Myerson said Blue Origin is building a new 750,000-ft2 manufacturing facility near Cape Canaveral, FL, US, where the company is installing a large Ingersoll (Rockford, IL, US) gantry-style automated fiber placement (AFP) machine to make large composite parts for the New Glenn. The plant, which is expected to open in 2018, will also house substantial additive manufacturing and CNC equipment.

Myerson noted that Blue Origin’s design and production philosophy — particularly given the disruptive, paradigm-changing nature of additive manufacturing — is blurring the lines that traditionally separate design personnel from manufacturing personnel. The result is an environment in which design engineers are increasingly pulled into the manufacturing environment, and manufacturing engineers are increasingly pulled into the design environment.

Web Industries

Web Industries Inc. (Marlborough, MA, US) announced at SAMPE the addition of two significant capabilities at its Atlanta, GA, US, Advanced Composites Center of Excellence. First, the company has added a Thermoplastic Composite Development and Qualification Center, specifically designed, staffed, and equipped to create processes that format thermoplastic carbon fiber prepreg materials, including PEEK, PEKK and PPS, for use in various fabrication technologies. The facility also will qualify equipment that will process the new thermoplastic composite formats.

Jim Powers, business development manager, says the new facility houses slitting equipment capable of cutting materials into tapes 0.0625 to 1 inch wide on a traverse wound spooling line. A second slitter/winder will be used to precision-cut wide rolls into 1 to 6-inch strips for planetary wound formats. The space is also equipped with machinery that can chop material into fiber flakes measuring 0.5 by 0.5 inch or 0.0625 by 0.5 inch, for use in compression molding. And, later in 2017, the facility will incorporate seaming technology. All of the process equipment is capable of achieving high precision tolerances down to thousands of an inch, contingent on incoming material quality.

Web's Thermoplastic Composite Development and Qualification Center.

“Web Industries’ investment in the new development and qualification center supports aerospace manufacturers with the means to make their thermoplastic composite concepts a reality,” Powers says. “The industry has long dreamed of having automated processing for thermoplastic composite manufacturing. This is now feasible thanks to advancements in fabrication techniques. As a result, an increasing number of aircraft parts are being designed to use thermoplastics.”

Powers notes that Web Industries’ extensive experience in formatting thermoset materials for aerospace applications makes the company well suited to lead new thermoplastic composites formatting. He says aircraft manufacturers have been particularly keen to see the composites material supply chain ramp up to provide consistent, high-quality, thermoplastics-based slit tapes, and Web sees this new capacity as a major first step in that direction.

Web's chopped thermoplastic prepreg materials.

The other capability added to the Atlanta facility is being offered through Web Industries’ CAD Cut division, which has opened a ply-cutting and kitting operation, designed to help aerospace manufacturers mitigate risk and outsource capacity.

The new facility includes five cutting tables, laser guidance devices and quality control systems. New video systems positioned above the cutting tables help maintain records management and traceability for every product.

The CAD Cut operation shares extensive freezer capacity with its Web Industries’ parent, whose freezers are located adjacent to the production area. The freezers enable CAD Cut to store advanced composite materials well in advance of deliveries, saving aerospace manufacturers inventory costs.

CAD Cut general manager Ben Winters says that the expansion to Atlanta allows CAD Cut to continue the mission to save manufacturers costs via logistics efficiencies, the elimination of scrap, and by freeing up cash and reducing waste associated with the purchase of inventory. The business also offloads the need for manufacturers to invest capital in cutting tables and production facilities. “We can accommodate minimum orders and long lead times and apply our decades of experience to the most challenging of advanced composite applications,” says Winters. “This leaves aerospace manufacturers free to concentrate on what they do best: employ their high level technical competencies on building finished aerospace components.”

The Atlanta operation began processing its first orders in May 2017. The business’ ability to deliver a disaster recovery capability in the form of its redundant manufacturing operations was a key to landing added business.

ELG Carbon Fibre

Frazer Barnes, managing director at carbon fiber recycling specialist ELG Carbon Fibre Ltd. (Coseley, Dudley, UK), reported at SAMPE that the company has established a sales and business development presence in the US by hiring Alasdair Gledhill, who is based in McKeesport, PA, and will carry the title of commercial director. Gledhill can be reached at alasdair.gledhill@elgcf.com.

Further, Barnes said ELG will, relatively soon, establish two facilities in the US. One, to be located near an unnamed aerospace manufacturer, will claim and process feedstock (uncured carbon fiber scrap prepreg). The second facility, to be located in the upper Midwest, will convert feedstock into one of ELG’s several recycled carbon fiber fabrics. The primary target market of ELG’s material, said Barnes, will be automotive. Click ELG Carbon Fibre for more information about the company’s products.

Steelhead Composites/Vartega

Also in the recycling arena, Steelhead Composites (Golden, CO, US), in partnership with carbon fiber recycling specialist Vartega Inc. (Golden), exhibited what they say is the first composite overwrapped pressure vessel (COPV) manufactured from continuous recycled carbon fiber tow.

Pressure vessel made by Steelhead Composites using Vartega recycled carbon fiber.

Steelhead Composites fabricated a Type 3 COPV using only recycled continuous carbon ber tow supplied by Vartega Inc. The fiber was recycled with Vartega proprietary process, and was sized by Michelman (Cicinnati, OH, US). The companies claim this collaboration marks the first time that waste continuous tow carbon fiber towpreg has been reclaimed, recycled and put back into the original manufacturing process.

“This project was an excellent demonstration of both the utility of recycled carbon fiber in end-use products and the value of industry cooperation when bridging technical hurdles,” says Sean Kline, Vartega’s VP of engineering. “Michelman and Steelhead’s expertise were invaluable, and we are excited about expanding these relationships as scale-up and optimization continue.”

“The project team took this vessel from concept to reality in just a few short months. I am extremely proud of everyone involved for their hard work and diligence to bring this all together,” says Andrew Maxey, Vartega’s president.” We will now take this success and go bigger. We’re planning a scale-up of our recycling process that should allow us to wind a much larger vessel in the not-too-distant future.”

“The recycled fiber from Vartega processed very well with the sizing from Michelman,” says Jake Schrader, Steelhead’s product development specialist. “It was handled just like any other dry ber would be in a traditional wet winding set up, and there were no issues with fraying or splitting. This recycled ber could have been virgin tow from the manufacturer.”

Chem-Trend

Mold release and mold cleaner manufacturer Chem-Trend (Howell, MI, US) introduced at SAMPE a new silicone-free, water-based mold release that contains <1% VOCs. Patrick Shannon, sales manager, composites, rubber and thermoplastics at the company, says this new release applies easily, requires no curing or buffing, is smooth to the touch but naturally tacky to prepregs, and wipes off quickly with alcohol. Shannon says the company is targeting the high-performance composites market with this mold release.

Stratasys Direct

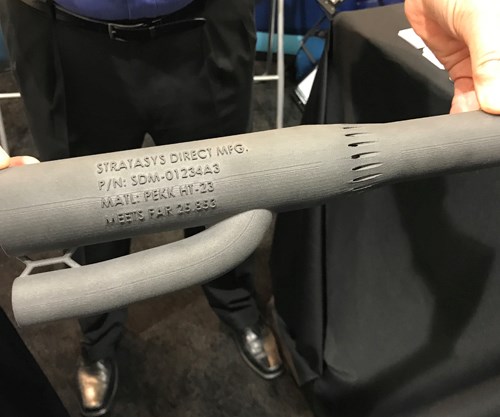

Frederick Claus, aerospace and defense business development manager at Stratasys Direct (Phoenix, AZ, US), an additive manufacturing (AM) service bureau and subsidiary of AM equipment specialis Stratasys, reported at SAMPE that Advanced Laser Materials (ALM; Temple, TX), also a Stratasys subsidiary, has developed a new polyetherketonketone (PEKK)-based resin for the selective laser sintering (SLS) AM process. The resin is formulated with milled carbon fiber encapsulated in the resin, which is said to enhance random fiber orientation and encourage good z-direction tensile strength. The material, called HT-23 (23% wt. carbon fiber), was developed in cooperation with Boeing to fabricate an aircraft engine air mixer (see photo). Claus says the material does not outgas and meets aerospace FST and UL V0 standards. The material is supplied by ALM and used by Stratasys Direct to make parts on an EOS P 800 SLS machine with an 18 by 22 by 28-inch build table.

Boeing mixer made via SLS using HT-23 PEKK/milled carbon fiber material.

Veelo

Nanomaterials specialist Veelo (Cincinnati, OH, US), formerly General Nano, exhibited for the first time under its new name. Veelo emphasizes products in four broad categories: VeeloSTRIKE multifunctional surface-ply material to replace metals for lightning strike protection; VeeloSHIELD for electromagnetic shielding applications; VeeloHEAT for uniform, fast heating of composites; and VeeloBLAC for ultrablack coating for blackbody calibrators and baffles. Veelo was a Boeing Supplier of the Year for Technology in 2016 and a Boeing Performance Excellence Award winner in 2015 and 2016.

Related Content

Hitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

Read MoreQueen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.

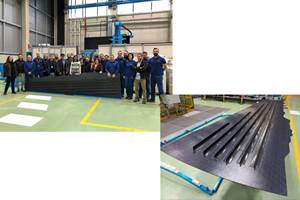

Read MoreClean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MorePlant tour: A&P, Cincinnati, OH

A&P has made a name for itself as a braider, but the depth and breadth of its technical aptitude comes into sharp focus with a peek behind usually closed doors.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read More