SAMPE 2018 new products target next-generation aircraft

The broader aerospace world might be patiently waiting for Boeing to officially announce plans to develop its New Middle-Market Airplane (NMA, or 797), tabbed as a replacement for the 757, but suppliers aren’t sitting on their hands.

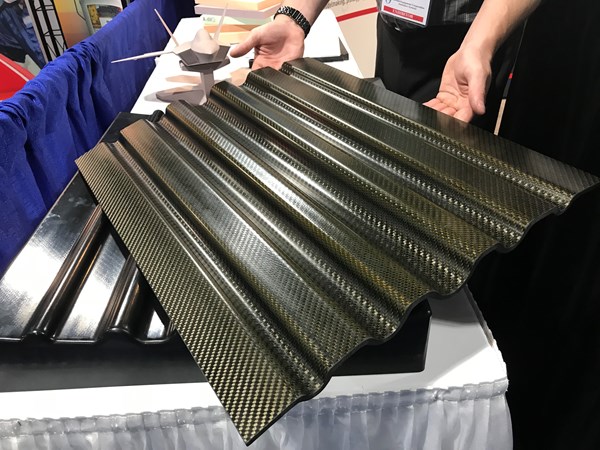

This beveled panel was molded with Airtech’s Beta Prepreg bezoxazine

tooling material on a mold made using DUNA-USA’s Black Corintho

high-density polyurethane tooling board.

The broader aerospace world might be patiently waiting for Boeing to officially announce plans to develop its New Middle-Market Airplane (NMA, or 797), tabbed as a replacement for the 757, but suppliers are not sitting on their hands. SAMPE 2018, May 21-24 (Long Beach, CA, US), proved that the aerospace composites supply chain has been busy developing new products for next-generation aircraft. Like the 797.

CompositesWorld caught up with a few of the innovations in the works or just introduced:

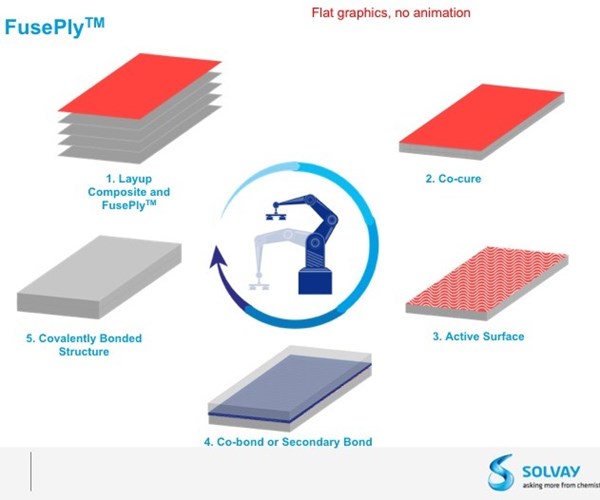

- Solvay Composite Materials (Alpharetta, GA, US) announced FusePly, an epoxy-based film that is designed to co-cure with a prepreg and provide a chemically active surface that reacts with functional groups in adhesives to create a covalently bonded structure. Solvay officials at SAMPE noted that FusePly’s chemically active surface differentiates it from traditional composite surface preparations, like peel ply and plasma treatment, which provide mechanical bonding only. FusePly, which Solvay believes will allow aerospace OEMs and fabricators to create reliable bonds and reduce mechanical fastener use, is compatible with 149-177°C amine-cured epoxy prepregs and is designed specifically for secondary or co-bond applications such as stringer-to-skin bonding. It can be processed in or out of the autoclave, is not affected by moisture or out time, and is said to have no mixed-mode failure. Solvay says that many OEMs are in the process of determining suitable applications for this technology.

Solvay’s FusePly is designed to provide a chemically active surface that is friendly to adhesive bonding. The resulting covalent bond could help aerospace OEMs reduce use of mechanical fasteners in aircraft manufacture.

- Hexion (Columbus, OH, US) introduced Epon FlameX, a halogen-free, non-particulate, non-additive chemistry for epoxies that provides strong fire/smoke/toxicity (FST) performance in aerospace, rail and marine interiors applications. It’s comprised of EPON FlameX Resin 9600 cured with EPIKURE FlameX Curing Agent 9700. This self-extinguishing resin meets the following standards: 60s vertical burn FAR25.853(a); smoke toxicity BSS7239; smoke density BSS7238. Epon FlameX can be used with resin transfer molding (RTM), infusion, filament winding and prepreg-based processes. It cures at 150°C and offers glass transition temperatures of 100°C (entry level), 130°C (intermediate level) and 190°C (advanced).

- American GFM (Chesapeake, VA, US) featured in its booth US120/CM10, a highly automated, three-zone marking/cutting/offloading ply-cutting and kitting system. It features an ultrasonic cutter that, American GFM guarantees, does not leave uncut threads. The ply-picking system features a six-axis robot that organizes plies into kits in an indexing drawer system. The entire system is adaptable to a variety of ply lengths; similarly, each of the three zones can be adjusted in length depending on throughput and ply size requirements. In addition, smaller systems can combine the marking and cutting function.

- DUNA-USA featured the latest iteration of its Black Corintho tooling board, and had in its booth an epoxy-sealed tool made from the material. The tool was used to mold an autoclave-cured part made using Airtech’s Beta Prepreg benzoxazine prepreg (see photo above). Black Corintho is a high-temperature, high-density, low-coefficient of thermal expansion (CTE) tooling board for prototyping, composite layup tooling, and master model making. Black Corintho offers service temperature of 400°F, 50 lb/ft3 density, 11.54 CTE at 100-250°F, 12.17 CTE at 100-400°F, and thermal conductivity of 280 mW/m3K.

- Start-up MITO Materials Solutions (Stillwater, OK, US) introduced at SAMPE its MITO T-Series, a non-nanotube nanoadditive for use with epoxies, vinyl esters and polyesters to provide a 100% increase in toughness and an 80% reduction in mechanical failure risk. The material, which is loaded into resin at 0.1-0.2 wt%, also offers a thermal resistivity increase of 12-14 deg C. MITO T-Series is being targeted first toward recreational vehicle sidewalls, which have a poor history of stress cracking, which leads to substantial costs in warranty repairs. Another targeted application is in marine base resins to resist temperature increase caused by gel coat magnification.

Related Content

Adhesives, material solutions promote end market versatility

CAMX 2023: Rudolph Bros. and Co. highlights its role as a prominent specialty chemical distributor and solutions provider with a display of high-performance adhesives, sealants, materials and more from well-known manufacturers.

Read MoreHenkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Read MoreBiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreHenkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More