Seemann Composites Inc. acquires Materials Sciences Corporation

Composites process innovator and materials engineering innovator formally combine forces.

Most people in the composites industry know Seemann Composites Inc. (SCI, Gulfport, MS, US) as the company founded by Bill Seemann, the inventor of Seemann Composites Resin Infusion Molding Process (SCRIMP). In fact, Bill is being honored next week at CAMX 2018 (Oct 15-18, Dallas, TX, US) with an ACMA Lifetime Achievement Award (see below).

I met Bill in the early 1990s when I was still new to the composites industry, and even newer to marine composites, having started out working with Kevlar and Nomex in aircraft applications. Bill was so gracious, explaining the development work he was doing at the time, testing various geometries of flow media for SCRIMP. We kept in touch over the years and I have tried to write about SCI’s developments, though much of it has been for defense projects, and thus, was not going to be written about in any detail by CW or any other publication. But I had no idea that SCI and Materials Sciences Corporation (MSC, Horsham, PA, US) had such a long relationship of close collaboration.

I wrote about MSC in 2015: “Materials Sciences Corp.: Multifunctional Composites”. Thus, I knew about their history with defense-related composites projects, specifically naval applications, such as an all-composite sonar window. But I was surprised by this announcement of SCI acquiring MSC. SCI president Sid Charbonnet explained it to me: “We’ve worked with Materials Sciences Corp. for over 25 years, and they have been an integral part of our team. But our working relationship has been pretty much a handshake and gentleman’s agreement. Now, we have finally solidified this relationship. We’re very excited about the positioning of our organization to meet the future needs of our customers across our wide range of services, including design and analysis, testing, product development and production manufacturing.”

Will Seemann, Bill’s son and CFO of SCI, led the acquisition and says it will allow the company to grow and expand capabilities while remaining nimble and geared toward innovation.

Seemann Composites Inc.

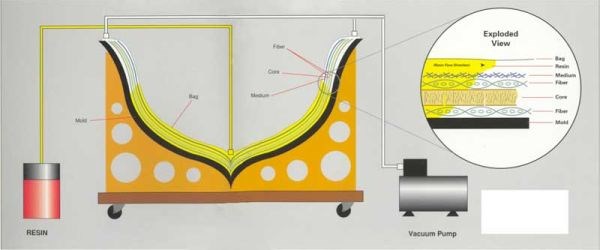

SCI was founded by Bill Seemann in 1987, specifically to develop SCRIMP. Bill had been a fiberglass boat builder and composite materials distributor for decades, based in the Gulf Coast region, including New Orleans and Gulfport, MS. SCI was founded on research and development innovation in composite processing and became a recognized leader in large scale resin infusion technology. SCRIMP is used worldwide and has been credited with starting an industry-wide revolution in vacuum-assisted infusion of composites.

|

|

SCRIMP is used worldwide for vacuum-assisted resin infusion of boat hulls like the Eagle 43 trimaran infused by H2X in France and many other structures, such as the Proterra Catalyst electric bus body infused by TPI. SOURCE: H2X and TPI (top) and SCI (bottom).

ACMA gives the following Lifetime Achievement Award tribute to Bill Seemann in recognition of his significant contributions to the composites industry:

William Seemann is largely responsible for laying the foundation for the composite material processes used in today’s marine industry. In the late 1960s, William Seemann’s interest in the research and development of composites fabrication led him to the invention and patenting of the C-Flex boatbuilding system, which enables builders to build one-off composite boats without a mold. In the years following, racing yachts built with C-Flex began to dominate sailing circuits around the world. The system has been used in more than 80 countries and is still being used today. In the 1980s, Seemann began research on vacuum infusion, which resulted in the development and patenting of the SCRIMP (Seemann Composites Resin Infusion Molding Process) vacuum infusion system. Seemann Composites was the first company in the world to make large parts with vacuum infusion, and the principles outlined in the original patent are followed in virtually all vacuum bag/vacuum infusion systems used to build boats, wind blades and much more.

|

|

|

Seemann Composites has produced structures for all branches of the US military, many working in collaboration with Materials Sciences Corp. SOURCE: SCI and MSC.

Today, SCI is primarily focused on manufacturing production components for US Department of Defense programs. It has fabricated and delivered thousands of advanced composite structures of all sizes and levels of complexity to all branches of the US military, as well as many major defense and commercial customers. It continues to supply some commercial products and also maintains a significant R&D capability to stay at the forefront of composites processing technology. SCI’s Gulfport production complex comprises four facilities totaling more than 160,000 ft2 and operated by a dedicated work force of 160 employees.

Materials Sciences Corp.

MSC was founded in 1970, and is an industry leader in the design, analysis and development of composite material solutions. The company’s 22,000-ft2 headquarters in Horsham, PA houses R&D, engineering, testing and prototyping functions. MSC also has a combined 45,000-ft2 of facilities space in Greenville, SC dedicated to the company’s product manufacturing and textile weaving capabilities. A third 6,000-ft2 applications engineering site is in Huntsville, AL.

Notably, prior to this acquisition by SCI, Materials Sciences Corp. completed the spin-off of its Countervail Products division, which will operate as a standalone company. It will continue to service its extensive customer base for the patented Countervail technologies and actively expand the unique vibration damping technology into broader application markets worldwide.

Both of MSC’s Principals, vice president and CTO Tony Caiazzo and president Tom Cassin, will continue their leadership roles within the company. “We’ve known for a long time that our customers, products and employees have benefited from our synergistic and close working relationship with SCI and that will be even more evident now that we are formally a part of the SCI group”, said Caiazzo. “This is clearly a win-win for our combined customer base and for the integration of the complementary capabilities of SCI and MSC,” said Cassin. “The ability to take projects more efficiently from concept to production will greatly enhance our response to the growing needs of the composites community.”

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More