Sizing Up Fiber Sizings

What glass fiber users need to know about sizings, and how new sizing developments are enhancing the performance of glass-reinforced composites.

Sizing is essential to glass fiber manufacture and critical to several key fiber characteristics that determine both how fibers will handle during processing and how they perform as part of a composite. "Glass is its own worst enemy," says independent consultant Bob Schweizer (Granville, Ohio), who recently retired after 32 years as a size and reinforcement chemist with Toledo, Ohio-based Owens Corning. Raw fibers are abrasive and easily abraded. "So you need to protect fibers from their neighbor fibers. Without sizing, we'd have nothing but a package of fuzz," he quips.

"Without sizing, it would be difficult even to make glass roving," adds Mike Gunther, president of Paradox Technical Consultants (Parker, Colo.), "and it would be virtually impossible for anyone to use it."

Sizing formulations also are the primary means fiber manufacturers have to adapt their glass products for particular applications and distinguish their products from their competitors'. While the performance of glass-reinforced composites certainly depends on compositional parameters, such as fiber volume and, in chopped fiber applications, aspect ratio (length divided by diameter), E-glass fiber itself, for instance, differs little from manufacturer to manufacturer. "You might have different filament or strand diameters, but it's still essentially the same glass, with pretty standard mechanical properties," says Andy Brink, vice president of Hydrosize Technologies Inc. (Raleigh, N.C.). But, with regard to interfacial properties, sizing is the primary variable.

Sizing also is one of the "black box" technologies in composites — glass fiber producers are very reticent to reveal much about the complex formulations they use. A working knowledge of the complex chemistry in sizing formulations is difficult to acquire even without the veil of secrecy. The good news is such knowledge is unnecessary even for many engineers at the fiber manufacturing facility, let alone engineers who design and build composite components. Yet there is much to gain from a general understanding of what sizing is and the ways in which it functions.

MAKE-UP AND FUNCTION

Glass fiber sizing is not a single chemical compound, but a mixture of several complex chemistries, each of which contributes to the sizing's overall performance. The primary components are the film former and the coupling agent. Depending on its formulation, the film former, so called because it forms a film on the glass strands, serves a number of functions, explains Brink, whose company develops and sells film formers. The film former is designed to protect and lubricate the fiber and hold fibers together prior to molding, yet also to promote their separation when in contact with resin, ensuring wetout of all the filaments. Film formers, with some exceptions, are chemically similar to the matrix resin for which the sizing is designed, Brink says.

The coupling agent, almost always an alkoxysilane compound, serves primarily to bond the fiber to the matrix resin. Gunther explains that silanes offer just what is needed to bond two highly dissimilar materials — the glass fiber, which is hydrophilic (bonds easily to water), bonds to a resin that is hydrophobic (insoluble in water and does not bond well to it). Silanes have a silicon end that bonds well to glass, and an opposing organic end that bonds well to resins.

Beyond these two major components, sizings also may include additional lubricating agents, as well as antistatic agents that keep static electricity from building up on the nonconductive fibers as they are formed and converted at high speeds — up to 100 mph, reports Gunther. Including additives for specialized, proprietary functions, a sizing formulation might contain eight to ten or more components. The interaction of these components with each other, with the matrix resin, and within a particular converting/fabricating environment is quite complex, yet reasonably well understood by sizing chemists.

MANUFACTURING CHALLENGES

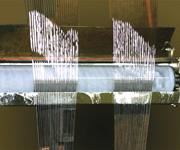

Glass manufacturers offer a wide array of products, each with its own unique sizing formulation, says Brink, because sizing chemists must meet a number of challenges, the first of which are encountered in the fiber manufacturing process itself. The glass manufacturing environment is quite harsh, says Schweizer, with the high heat of the furnaces and the corrosive components that can be released when silica sand, the raw glass component, is melted. "While sizing is being applied, the glass goes from furnace temperatures very quickly to temperatures at which you could hold it in your hand," says Sean D'Silva, manager for global product development at Johns Manville Corp. (Denver, Colo.). "And the size bath is an emulsion, in which the shapes of particles and their surface tensions — the physics of the whole thing — is amazingly complex." New glass filaments, covered with water, are sized as soon as they exit the bushing through which they are extruded at very high speed. "The manufacturer has a few milliseconds to apply a thin coating before something happens to that bundle of glass," Gunther points out. "It's clear that this is not a low-tech endeavor by any means!" That thin film then must immediately protect the fiber while it travels around guides and other stress-inducing parts of the fiber manufacturing line, yet the coating must also possess all the characteristics needed to fulfill its mission during subsequent fabrication and product end-use. This is especially important if the fiber will be used to make woven reinforcements or be subjected to other abrasive processing during composite fabrication.

High-speed processes typically use glass with greater amounts of sizing on the strands. Measured in terms of loss on ignition (LOI) — which quantifies the sizing in terms of weight percent of the glass product by burning the sizing off the fiber — a high-speed process might employ fiber with a 0.8 percent LOI while a lower speed process might only require 0.4 percent LOI. Gunther cautions that high-speed processors must watch not only the nominal LOI, but also LOI distribution on a product. "With a target of 0.8 percent LOI, some portions of the fiber will have over 1 percent sizing while other areas might have 0.4 percent or less," Gunther explains. "With high-speed processes, the portions with low coverage will give you problems."

Yet overly high LOI also can create problems. "If a large percentage of the size chemicals still remain once the glass is in its final resting place in a composite," says Gunther, "it can be detrimental to bonding." This highlights a key challenge for sizing chemists: the sizing must hold the glass strand together and provide lubrication so that it survives the stresses of conversion and fabrication. For example, some size formulations must provide high "strand integrity" where rovings pass circuitously, at high speeds, over a number of rollers and/or through feed eyes, as is the case in pultrusion and filament winding processes. Yet once the roving is placed in its final position, those components should not interfere with the sizing's ability to release the filaments within the strand at the appropriate time for good wetout and effective adhesion to both the glass surface and matrix resin.

Characterizing the size chemist's job as a "big balancing act," Gunther suggests that if one could isolate the demands placed on the glass fiber by its three lifecycle phases — glass manufacturing, composite converting/fabricating, and finished composite component — one would develop a different sizing formulation for each group. Like fabrication, some manufacturing requirements are directly at odds with the characteristics desired in the end product. For example, while polyurethane-based film formers help protect the roving and aid in adhesion between fiber and matrix, "it is very sticky and tends to build up all over the manufacturing equipment," Gunther explains. "Tackiness on anything the glass strand touches can cause filaments to start breaking, so manufacturers incur downtime to keep forming environments clean. If you didn't need the film former downstream, you'd make a sizing that was very lubricious, and you'd be able to wash everything down with water." Conversely, compounds that help with handling, as noted above, typically do not aid adhesion.

In practice, however, sizing chemists must avoid tradeoffs or compromises between the final composite properties and the overall processability. "Without protection, you can't process the glass, and without adhesion between the fiber and the resin, you don't have reinforcement," says Phil Schell, R&D director for Saint-Gobain Vetrotex (Wichita Falls, Texas). "So we have to do both, and do them very well." In thermoset resins, Brink says, the general strategy is to design a film former that will dissolve in the resin, leaving only the silane coupling agent, which facilitates the bond between glass and matrix. On the other hand, film formers often contribute to fiber-resin adhesion in thermoplastics, and therefore can remain intact within the resin. In applications using chopped glass and thermoplastics, the shear force applied when fiber and resin are mixed in a twin-screw compounder aids in the dispersion of the glass into the matrix resin.

In both thermoset and thermoplastic applications, the results thus should not be characterized as a compromise. "The only real tradeoff would be on our processing speeds, not on the material," D'Silva says. "For the glass itself, I haven't heard of anything that couldn't be done because of conflicting properties. Some chemicals are not used because they can't be applied at the appropriate speeds. More science will allow us to apply sizing faster. But so far, whatever properties have been needed, we've been able to produce."

RESIN COMPATIBILITY

The chemist's formulation strategy is influenced most significantly by the selected resin system. A sizing can be specifically formulated for a particular resin system or more generally for compatibility with several systems. The former provides the greatest opportunity to optimize fiber/resin performance. For instance, if a polypropylene (PP) resin is selected, a sizing designed specifically for that PP matrix might produce 200 percent better mechanical properties than a fiber sized for, say, nylon. On the other hand, some resin families possess enough similarities that glass manufacturers can offer one sizing that will make a glass product compatible with multiple resin systems. In fact, all glass manufacturers offer "tri-compatible" products that can be used with polyester, vinyl ester and epoxy resins.

One choice an end-user must make, then, is between a "multicompatible" sizing or one targeted to a specific resin. According to Schell, those who choose the former must accept a performance penalty ranging from 2 to as much as 10 percent of the end product's mechanical properties, depending on the product, resin, process and application. Therefore, customers are typically driven to a multicompatible product by two factors unrelated to performance: "Capital and convenience," he says. "If you can utilize a single product that works well in several applications or resin systems, you won't tie up capital in the inventory of two products, and you avoid the inconvenience of creeling products in and out." However, Bob Brannon, technology director at Fiber Glass Industries (FGI, Amsterdam, N.Y.), warns that tri-compatibles may not be a good choice for all resins within a category. He notes, for example, that common anhydride-cured epoxies work well with tri-compatible glass products, but points out that more specialized amine-cured epoxies do not.

Targeting a sizing for particular resin system is recommended in critical applications in which performance knockdowns are unacceptable and/or production volume is large enough to justify the inventory and minimize creel changeouts. High-pressure filament-wound pipes are a prime example of an application in which targeted sizings are not only desirable but essential, says Brannon. Fatigue life in these pipes is measured in "cycles to weep," that is, the number of times the pipe can be taken to full pressure before liquid starts seeping through its walls. The pipe's fatigue resistance, he maintains, could be thousands of times better with the right sizing formulation.

PROCESS COMPATIBILITY

Second to the matrix in terms of impact on sizing selection — and only by a narrow margin — are the conversion and fabrication processes to which the fiber will be subjected. "Ideally you're producing a chemical reaction between the sizing, the glass surface and the resin," explains Brink. "Time and temperature greatly affect that reaction." For example, the extent of reaction during pultrusion, with its relatively high temperature and rapid processing rate, could be quite different from the reaction obtained during vacuum-assisted resin transfer molding (VARTM), with its relatively low temperature and slow processing rate.

FGI sales director Tom Bruce points out that very slow processing rates, such as those that characterize composite wraps for seismic retrofitting, places special demands on sizing. "The fabric is saturated in resin, then carried to its final placement," he explains. "A size formulation that allows fast, high wetout would never work" because the compounds within the sizing that hold the strands together would have dissolved before the fabric was positioned, and the fabric would not hold its form.

Recently developed long fiber-reinforced thermoplastic (LFRT) processes have attracted a good deal of attention. For example, Johns Manville's StarRov 473A sizing, launched in Europe, is targeted at new automotive applications of long-fiber glass/polypropylene components, D'Silva reports. "We worked closely with machine manufacturers both to ensure good fiber dispersion in the polypropylene and to maintain long fiber length as the glass passes through the extrusion screws," he explains. A second advancement, not yet launched but targeted to high-throughput long-fiber reinforced thermoset applications in the infrastructure market, will protect the glass fiber from damage in the high-throughput process yet provide high-performance characteristics needed in the end product.

END-USE COMPATIBILITY

The third category affecting sizing formulation involves the properties desired in the end product. For example, Schweizer notes, "In nylon applications, a specific size formulation might be offered for the high hydrolysis resistance (imperviousness to hot water) required in automotive underhood coolant systems — sizing affects that property."

And a final but in no way insignificant factor with great impact on sizing formulation is whether the strand will become a continuous reinforcement or will be chopped for use in sprayup application or in products such as sheet molding compound (SMC), says Schell. "For products that are going to be chopped, we formulate a stiffer sizing, so that as it is chopped it disperses quickly into individual strands," he explains. "But for a filament winding, pultrusion or weaving input, where the product is required to maintain its strand configuration until it is wet by the resin in the final part, we produce a softer, more flexible sizing."

CONSULT AND TEST!

Given the complexities of the sizing challenge, the best resource for determining which sizing to specify, Brink believes, is the fiber supplier. FGI's Brannon concurs. "For many of our customers, more than one size formulation could work," he says. "So we work with them to see which formulation processes best."

That said, Brink warns that test runs by the end-user are absolutely essential. Even when fiber recommendations are on target, the final composite properties can vary significantly. "The chemistry of all the different sizing components — which is proprietary — and how they react with each other within each process and with each resin formulation, all affect the adhesion between the fiber and resin," says Brink. Resin formulations, too, contain additives that are proprietary. Consequently, glass suppliers cannot comprehensively predict how each sizing will react with each particular resin system. Brink notes by way of illustration that in a previously conducted study of seven different glass products, all recommended for use with a single resin system he had specified, the final strength of test coupons made from these recommended products varied by as much as 28 percent.

"Specifying a sizing designed for the resin gets you started," Brink says, "but then you have to narrow it down based on the particular resin formulation and the fabrication process. There often needs to be a joint solution between the resin and fiber manufacturers."

The benefits of such collaborations can go far beyond sizing selection. "Changing size chemistry isn't always the answer," Brannon points out. Pultrusion, for example, must balance and closely control a large number of processing variables, including the catalyst system, line speed, zone temperatures and exotherm rate. The choice of glass products, Brannon cautions, must therefore be considered in concert with all of the processing parameters In one case, a customer who was generating fuzz build-up thought that he needed to run his pultrusion line at a slower speed, but the problem got worse. "He was actually running the line too slowly for the wetout characteristics of our product," Brannon explains. "The film former was solubilizing and wouldn't hold the strand together as long as it needed to." The counter-intuitive — and more productive — solution to the fuzzing problem, therefore, was to run the line at a higher speed. Likewise, when one filament winding customer was experiencing heavy resin drainage off its parts, FGI suggested a sizing with a slower wetout rate, and this helped the customer virtually eliminate the costly resin drain-off. "When our customers can communicate well what their requirements are," Brannon concludes, "a joint effort can get the best performance out of the fabrication process, the resin and our glass product."

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More