SMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

For more than a half century, sheet-molding compound (SMC) has been a well understood and broadly applied composite technology, used in industries as diverse as automotive, rail, aviation, marine and building/construction. But recent technological advances in reinforcements, fillers, matrix resins, and compounding and processing techniques have significantly broadened a once narrow definition. Source | Navistar International Corp.

Originally defined as a sheet-form, compression-molded, B-stageable thermoset composite, sheet molding compounds (SMCs) comprised of unsaturated polyester (UP) or vinyl ester (VE) matrices (or blends of the two) reinforced with chopped glass fiber, plus additives and mineral fillers, have found wide use for more than 50 years in many industries. And unlike others, this very atypical form of prepreg needs no cold storage during transport and prior to molding, but can be stored at room temperature.

In Part 1 of CW’s SMC update (May 2017; see SMC: Old dog, new tricks), a variety of newer reinforcements and fillers were shown to have improved SMC performance, most notably by reducing compound densities to levels that make SMC competitive, weight-wise, with aluminum and steel, a game-changer in automotive applications. In Part 2, the multiplication of resin and compounding options for this versatile class of composites are challenging conventional assumptions about what we mean by SMC. Indeed, the line separating this material and continuous-fiber prepregs has blurred to the point that there are those who wonder, “Do we need a new definiton for SMC?”

New matrix technologies: Higher mechanical and thermal performance

Alongside the significant changes to reinforcements and fillers in the SMC recipe, work continues to broaden SMC beyond its conventional reliance on UP, VE and hybrid UP/VE matrices. Many resin suppliers and compounders now say they’ve developed and commercialized hybrid resin systems that contain two, three and even four or more polymer systems, while others are working on unconventional single-resin matrices. Some of this work is intended to make SMC more effective in true structural applications. VE, for example, is a fully saturated polymer (with no open valences) so it doesn’t bond well to carbon fiber without new work on sizings. Another reason is the desire to reduce or eliminate volatile organic compounds (VOCs), particularly styrene, which, in turn, has an impact on compounding.

One additional resin in the mix is polyurethane (PUR). Since the early 2000s, small amounts of PUR have been added to conventional SMCs to help improve toughness and reduce blistering and paint-pop issues. However, PUR could be a matrix for SMC in its own right, owing to its higher mechanicals, damage tolerance, chemical resistance, moldability and excellent adhesion to numerous reinforcements and fillers. The one impediment to that status is that PUR has, historically, cured too quickly to be practical for conventional SMC compounding. However, a multi-year development project aimed at creating a stronger, tougher composite system to meet the railway industry’s stringent flame/smoke/toxicity (FST) requirements provided the opportunity to give it a try. Partially funded by the provincial government of Ontario, Canada, the project involved research institute Fraunhofer Project Centre for Composites Research (FPC, London, ON, Canada), resin supplier Huntsman Polyurethanes (Auburn Hills, Miss., U.S.), and fiberglass source Johns Manville (Denver, Colo., U.S.).

Three key elements made the project feasible. The first was Huntsman’s prior work to chemically decouple PUR viscosity build from resin “snap cure.” This permitted formulators to build in both a long latency/outlife at low viscosity, which ensured thorough infusion and fiber wetout of even large parts, and a rapid cure (see A new "tunable" polyurethane could revolutionize composites). The second was FPC’s work, along with co-owner Fraunhofer Institute for Chemical Technology (F-ICT, Pfinztal, Germany) and machinery OEM Dieffenbacher GmbH (Eppingen, Germany) on the direct-SMC (D-SMC) process, where compounding occurs very close (physically and temporally) to molding without the need for the 48- to 72-hour maturation period that is common with conventional SMC. The chemistry of the VITROX resin system that Huntsman is supplying more or less necessitates making PUR SMC via a direct process.

“The great thing about urethanes is they react with everything, but the bad thing about urethanes is that they react with everything, too,” quips Dr. Michael Connolly, program manager – urethane composites at Huntsman Polyurethanes. “Still, VITROX chemistry allows us to separate out snap cure at high temps vs. an early maturation stage … and to separate exotherm control from molding,” he adds. “That feature has proven useful for a lot of composite processes.” SMC is now one of them.

The third element to the project’s success was Johns Manville’s work on sizing chemistry. Since calcium carbonate (the most common SMC filler) and some urethane catalysts can be incompatible, alternative fillers (in this case, glass microspheres and milled glass) had to be used. In fact, specific grades of chopped and milled glass and glass microspheres were selected so as not to inhibit the reaction of the PUR matrix, because some sizing chemistry also can be an issue with the reactive PUR matrix.

“Standard SMC fiberglass sizing needs to be styrene-soluble for good wetout, but that doesn’t work with PUR resin systems,” explains Dr. Klaus Gleich, senior research associate-Corporate R&D, Johns Manville. “We had to watch the film former and other sizing components, because depending on chemistry of the glass sizing system, it can inhibit or kill a catalyst or cause foaming. You always have to adjust glass chemistry for new resins systems, so we had to modify sizing chemistry to optimize fiber wetout and coupling and to avoid inhibiting the PUR reaction. Fortunately, we’d already done development work with urethanes in LFI [long-fiber injection], so it wasn’t too difficult. You want the composite very light and structural, but you also want it affordable.”

Of 15 initial formulations of fire-retardant PUR SMC that were produced and tested, four were found to have comparable or superior performance to VE SMC, but with much faster cure times. Daniel Park, FPC research engineer, also reported tensile strength increases of 23% (118 MPa), tensile strain-at-break increases of 25% (an elongation at break of 1.7%), and 40% higher energy absorption as measured by Dynatup impact vs. UP SMC formulations. The composite also showed 25% higher Dynatup impact vs. VE SMC formulations with similar fiber content and filler levels, which were used as controls. Grades with a Class A surface are said to be encouraging but still need work to improve finish. They work well in the D-SMC process where the material is compounded and then molded within a short time, with no maturation step.

Although they are in an early stage of development, PUR SMC systems have demonstrated good mechanical performance and flame-spread values and are VOC-free. They do not, however, yet meet the railway industry’s smoke requirement. More work is needed, but because the formal project has come to an end, that work will have to wait until additional funding and new partners can be found.

Other research on the agenda includes evaluating additional filler systems as well as unfilled structural systems with higher reinforcement levels vs. the preliminary formulations. Park notes that the current PUR SMC systems FPC tested are at the practical limits of glass content (60 wt%). “Carbon fiber-reinforced PUR or epoxies or even vinyl ester are promising because part and mold design know-how for SMC are already well understood, and the process allows you to do near net-shape forming of a 3D, quasi-isotropic part at very low scrap rates relative to other carbon fiber composite molding processes,” he adds.

Connolly says that FPC and Huntsman did additional screening work after the formal study ended to evaluate PUR with 50K carbon fiber tow from Zoltek: A Toray Group Co. (Bridgeton, Miss., U.S.) in the D-SMC process. He says the work looks very promising, with the carbon/PUR SMC showing comparable or somewhat better tensile and flexural strength than large-tow carbon fiber/VE SMC. Demold times were as low as 2.5 minutes at 130°C and 2 mm part thickness to yield a resin Tg of ~125°C. More work is underway to evaluate molding of 3D designs, conduct extended freezer-storage studies and further explore impact testing. “We’d love to cooperate with interested companies for glass or carbon fiber [SMC] technology development, as there is only so much technology push we can do on our own,” Connolly notes. “We need some pull now. We don’t care where the pull comes from, but the most obvious choice would be from the molder/compounder level.” Preliminary work suggests that PUR SMC may find a fit in applications that require greater durability and toughness.

Interesting research also is underway in the epoxies arena. VE, itself, is synthesized from an epoxide, so epoxy-modified VEs and VE/UP blends have been available for some time. However, resin supplier Hexion Inc. (Columbus, Ohio, U.S.) has recently commercialized a 100% epoxy grade specifically designed for automotive SMC. In addition to high mechanical properties, another advantage of epoxy SMC is that it is inherently compatible with epoxy prepreg: The two products can be co-molded to achieve a “tailored” composite part.

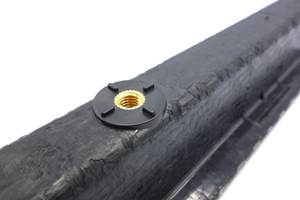

Another interesting area of research is being done in the area of epoxy-SMC. Hexion Inc. has recently commercialized a B-stageable, 100%-epoxy grade specifically designed for automotive SMC, with high mechanical properties, no styrene, and low VOCs. Inherently compatible with epoxy prepreg, epoxy SMCs can be co-molded with them to achieve "tailored" parts. The new system is said to be a low-viscosity formulation with good flow and excellent fiber wetout for high fiber volume fraction with either glass or carbon fiber and has been specifically modified to match the conventional maturation step of VE- and UP-SMC. It recently was molded into an automotive seat frame and parts reportedly filled completely, including ribs and bosses. Source | Hexion Inc.

The new system — EPIKOTE resin TRAC 06605 and EPIKURE curing agent TRAC 06608 — is said to be a low-viscosity formulation with good flow and fiber-wetting characteristics, specifically modified for the SMC process. It can be supplied with an internal mold release agent (HELOXY TRAC 06805) to expedite demolding.

Reportedly, the system is styrene-free, low in VOCs and fully compatible with other epoxy composites on the market. Further, it has been formulated to offer excellent wetout and maximum fiber volume fraction (FVF), and it works with all common SMC reinforcements, including fiberglass. Hexion reports good quality in molded parts at up to 55 vol% reinforcement, using automotive grades of fiber. Typical molding conditions are 3 minutes at 150°C or 5 minutes at 140°C, with the lower-temperature option yielding the better surface finish. The Tg of this low-viscosity system is ~100°C, so molded parts are said to be able to survive E-coat (electrophoretic painting/rust proofing) processes — at least on European if not North American lines — and can handle paintline temperatures as well, as long as parts are shielded and well-supported during the processes.

“It was quite a product design challenge to create a B-stageable system that directly replicates the maturation step typical of UP and VE systems in pure epoxy resin,” notes Sigrid ter Heide, global market development manager, Transportation EPCD, Hexion BV (Rotterdam, The Netherlands). The current formulation is driven by temperature and needs 7 days of maturation at room temperature or 3 days at 30°C.

Recently, the new system was trialed using 45 vol%/57 wt% carbon fiber, Pyrofil 15K with 0.4% epoxy-compatible sizing from Mitsubishi Chemical Carbon Fiber & Composites Inc.(Sacramento, Calif., U.S.) on an automotive seat-frame structure with a surface area of 0.35m2. The initial charge area was 25% and, reportedly, parts filled the mold/part geometry completely, including ribs and bosses.

“There definitely is a market need — and many market requests from OEMs and molders — to develop a system like this,” adds ter Heide. “The industry had the capacity to develop such a material, plus epoxy is well known for its compatibility with carbon fiber for higher strength applications.”

A. Schulman (now LyondellBasell), which reports it has produced glass/epoxy and carbon fiber/epoxy SMC since 1987, has recently introduced four grades of “next-generation, styrene-free, low-VOC” epoxy SMC reinforced with 3K- and 12K-tow chopped carbon fiber as well as continuous-fiber mat. The new materials are said to be built on technologies historically used in aerospace, military and defense markets, but specifically formulated for automotive SMC. The grades offer higher mechanicals than carbon fiber-reinforced VE SMC and have a Tg that comes in between Tan Delta and storage modulus values of 125°C and 160°C respectively, which should make them compatible even with higher temperature North American E-coat lines. Customers in Europe and North America reportedly are now sampling these materials. In addition, the company also produces SMC grades with phenolic, as well as high-temperature polyimide and bismaleimide resins reinforced with carbon or glass or both for aerospace and oil and gas customers.

Additionally, Magna Exteriors (Troy, Miss., U.S.) reports that since 2008-2009, the company has used in-house compounded epoxy-urethane hybrid SMC, based on Derakane VE resin from Ashland, LLC (Dublin, Ohio, U.S.). Depending on application performance and cost requirements, Magna also uses hybrid-UP and modified-VE chemistry from several suppliers.

New compounding changes:The move to low- and no-VOCs

Traditionally there have been two methods for compounding SMC — more common and lower temperature solvent-based compounding or higher temperature hot-melt compounding, which requires specialized equipment and is similar to that used by prepreggers. Compounding of SMC is changing and is doing so in direct reaction to recent European Union and North American VOC reduction mandates, specifically, those aimed at styrene emissions. Unfortunately, styrene — the low-cost but highly effective diluent that formulators and compounders favor for solvent-based compounding to reduce resin viscosity for good fiber and filler wetout, improve handling, drive crosslink density, increase shelf life, reduce auto-polymerization issues and enhance UV stability — isn’t easily replaced. Resin suppliers and compounders now face a difficult choice: Either find non-styrene diluents that work well enough for them to continue using solvent-based compounding methods, or switch to hot-melt processing methods that will require significant capital expenditures. There are pros and cons associated with each approach.

In the pursuit of low- or no-VOC resin systems for both SMC and true prepreg compounding, Polynt-Reichhold LLC (Durham, NC, U.S.) has led the charge. “Five years ago, 90% of the resins we made for SMC and prepreg were styrenated,” says John Ilkka, Polynt-Reichhold’s business development manager – advanced materials. “Our leadership at the time challenged our R&D team to look at alternative ways to create polymers without styrene. While we considered other reactive diluents, like vinyl toluene or vinyl benzene — which also are currently under scrutiny — our management was concerned that if we went down that path and regulatory authorities expanded the list of prohibited solvents, then we’d be back to square one again. Because of that, we’ve opted to take the harder route and create a less expensive system without reactive diluents.”

“Our strategy has been focused on the structural side, on delivering snap-cure, room-temp storage composite solutions with zero VOCs that work with either glass or carbon and that emphasize molding productivity for SMC and prepreg applications,” adds Steven Hardebeck, Polynt-Reichhold technology director North America – composites. “Fortunately, the initiator and cure mechanism is the same between our older styrenated SMCs and the new hybrid systems, so we can match conventional SMC cycle times without losing productivity.” The end-result of all the hard work says Hardebeck is no-VOC systems that don’t require refrigeration, offer longer outlife, improve productivity, are E-coat compatible and are less costly. On the other hand, this work didn’t come easily. “We’ve had to adjust chemistry and go with multi-polymer systems that allow us to get a product that’s good at wetout and can be handled, has the processing characteristics molders want and, when cured, provides the thermo-mechanical characteristics the customer needs,” he adds. “That forced us to move into high-temperature liquids that are solid at room temperature and hot-melt applications featuring three and four polymers.” He notes that the company has filed patents on some of the work and that Polynt-Reichhold has “some very smart polymer chemists who’ve met almost every challenge we’ve sent them.”

Commercial applications of Polynt-Reichhold’s no-VOC VE SMC include the battery box and tray on the 2014 Chevrolet Spark electric vehicle from General Motors Co. (GM, Detroit, MI, US), which are molded by Continental Structural Plastics (CSP, Auburn Hills, Miss., U.S.) (Onboard protection: Tough battery enclosure), and floorboards on the 2016 Chevrolet Corvettes from GM that are produced by Molded Fiber Glass (MFG, Ashtabula, Ohio, U.S.).

“VOC emission requirements won’t go away,” states Dr. Mike Siwajek, CSP VP R&D. “They may be slower to phase in here [in the U.S.] than in China and Europe, but you can see emissions [requirements] tightening all over the world.” He notes that many systems today meet current requirements, and that CSP as well as others are working on alternative chemistries — including thermoplastics. He does caution that such modifications, including moving to hot-melt systems, have their effects on compounding, molding and handling — in some cases, part properties improve, but in others, they can suffer. “Since styrene chemically crosslinks unsaturated polyester and vinyl ester systems, when you make styrene go away, the crosslinks go away unless you make it up with some absolutely open catalysts,” he adds.

“Currently, both hot-melt and solvent-based [compounding] approaches to lowering styrene come at increased costs to the compounder, and hence to the molder and OEM,” notes Terrence O’Donovan, VP - marketing and sales, Core Molding Technologies (Columbus, Ohio, U.S.). “As a compounder and molder, we favor a solution based on alternate resin systems.” He feels that because the known approaches currently bring higher cost, that molders and OEMs need to demonstrate a commitment to the end result — lower residual styrene (and VOCs) — by accepting some cost increases in the short term. “If that happens, then commercialization will move more quickly,” he predicts.

“When you eliminate styrene and go to a hot-melt system, handling and processing can become challenging,” notes Robert Seats, North American technology director at Ashland. “The prepreg folks know how to handle hot melts, but trying to translate that technology to an SMC machine can be trickier because hot-melt systems process at significantly higher temperatures than traditional paste. On the other hand, with hot melt, you can lay down significantly more pounds of material per hour to get higher productivity.”

“When you’re talking about styrene emissions, it’s important to remember that on the SMC side, we’re using a closed-mold process,” adds Mark Harber, business manager, AOC (Collierville, Tenn., U.S.). “That means it’s relatively easy to engineer out styrene emissions for both the worker and the environment.” Because SMC is molded at high temperature, he explains, that fact can help solve part of the problem. VOCs are flashed off, captured and incinerated during the molding process. AOC’s approach, therefore, is to work with non-styrene diluents, such as vinyl toluene and acrylates. Harber adds, “If you’re looking at something other than traditional styrene, you might be able to make SMC more UV stable. There can be a downside, but there also can be an upside to these changes.”

“This is a very exciting time for composites,” adds CSP’s Siwajek. “After 45 years, we have a solution, and people need to tell customers, ‘Don’t lose heart, these technologies are filtering out, and carbon fiber is knocking on the door.’”

Core’s O’Donovan expands on this, with the auto industry in mind: “For intermediate-volume programs, studies have shown that SMC composites are the economical choice against steel and aluminum. With all the advances in resins and fibers that are driving down density while maintaining or improving strength, SMC composites are a legitimate choice for new applications.”

Related Content

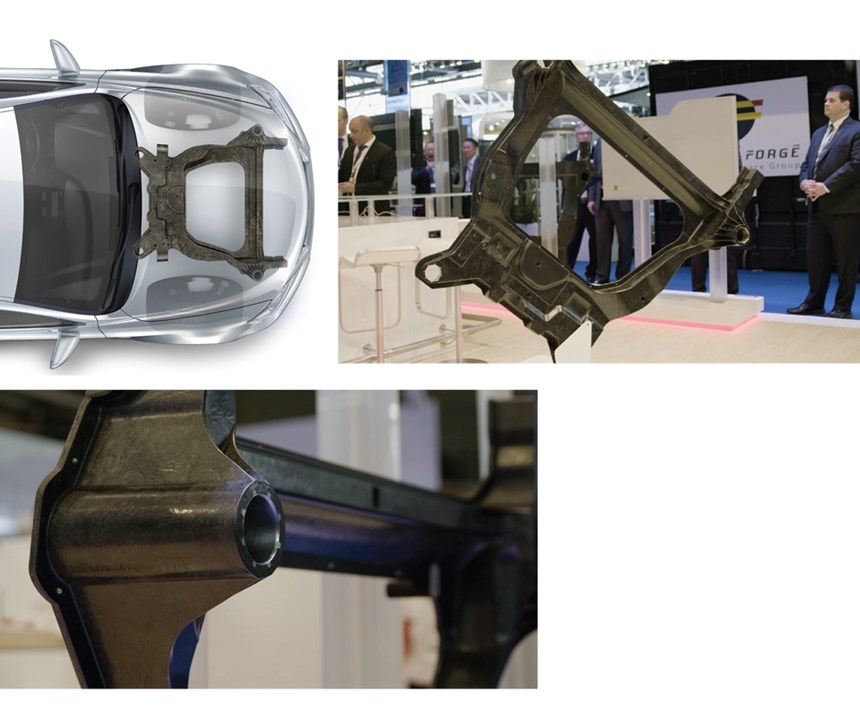

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

IACMI to host two-day SMC workshop

The “SMC 101: From What to Why” workshop, led by industry leader Jim Plaunt, will take place at IACMI SURF from August 21-22, 2019.

Read MoreSMC is on the upswing (and check out this design competition)

There’s a lot going on with sheet molding compound (SMC) right now, including a design competition for best SMC design, with the winner announced at Composites Europe.

Read More

.jpg;width=70;height=70;mode=crop)