Next-Gen Aerospace 2019 Issue

April 2019

Digital Edition

Features

Featured articles from the Next-Gen Aerospace 2019 issue of CompositesWorld

A Flight Plan for Next-Gen Manufacturing

Learn more about the materials and processes that will shape next-generation aircraft in a collection of stories from Modern Machine Shop, Additive Manufacturing and CompositesWorld, available to read or download for free.

Read More

Automated, in-situ inspection a necessity for next-gen aerospace

Inline inspection technologies continue to evolve with the aim of providing faster and more accurate part inspection.

Read More

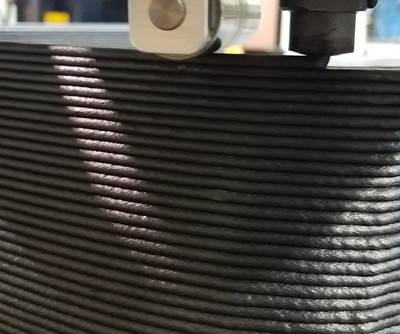

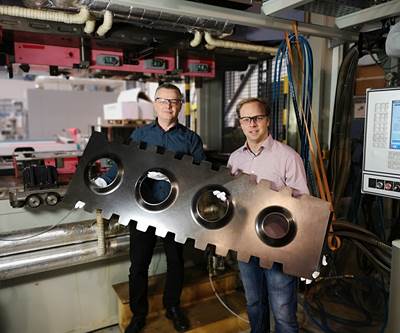

Big additive machines tackle large molds

In commercial aerocomposites fabrication, molds reign supreme, but they are expensive. Large-format additive manufacturing systems are poised to make production-ready molds quickly and affordably.

Read More

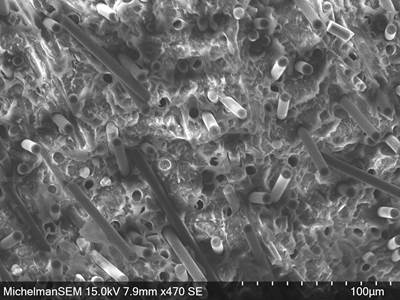

Fiber sizing, tow spreading and the quest for encapsulation

Fiber sizing is easily overlooked by composites fabricators, but it will be increasingly important to optimization of fiber performance.

Read More

HP-RTM for serial production of cost-effective CFRP aerostructures

Merging automotive process and tooling with aerospace quality to meet increasing production rates.

Read More

Mission Critical: An AM Breakthrough in Commercial Aviation

The GE9X is the first commercial aircraft engine to reach production with significant additive content. The story of GE’s accomplishment and why it matters.

Read More

Next-generation aerospace: shaping the supply chain landscape

The global commercial aerospace industry is at a unique time.

Read More

Plant Tour: STELIA Aerospace, Méaulte, France

Supplier of Airbus fuselage sections pushes boundaries of hybrid aerostructures production, assembly and thermoplastic composites.

Read More

Spirit AeroSystems invests in qualification program with Toray prepreg

The world’s largest aerospace tier supplier seizes the opportunity to develop its own allowables for a carbon fiber prepreg, setting an important precedent.

Read More

Tackling the Aerospace Supplier’s Dilemma: Scalability

Automation and robotics can go a long way toward increasing capacity and growing a business dedicated to aerospace manufacturing. But Trinity Precision has learned that refining the indirect and unseen aspects of its operations can be just as valuable.

Read More

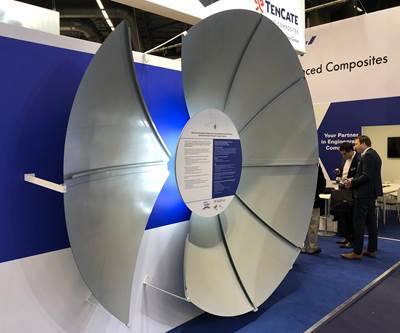

Thermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

Read More