Plant tour: Spirit AeroSystems: Prestwick, Scotland, UK

Global aerostructures giant Spirit AeroSystems ventures into out-of-autoclave (OAA) composites manufacturing via vacuum infusion.

Although Spirit AeroSystems is a relatively new name in aerospace, having been founded in 2005 with the acquisition of the The Boeing Co.’s (Chicago, IL, US) facilities in Wichita, KS, US, it acquired with them a long and noteworthy history, going back almost 90 years. The earliest incarnation goes back to 1927, with the Stearman Aircraft Co., which moved to Wichita from the US state of California. Stearman was then purchased in 1928 by Boeing, and the site went on to produce some of Boeing’s most famous aircraft, including the B-29 Superfortress bomber, the B-47 Stratojet and the B-52 Stratofortress.

Following the founding of the new company in 2005, Spirit went on in 2006 to acquire another established aerostructures business unit, this one from BAE Systems (London, UK) in Prestwick, Scotland, UK. The European operation is now one of the largest airframe suppliers to Airbus — in particular, major wing structures. Spirit has gone on to expand its business globally, with locations in Malaysia, France and North Carolina, US. Spirit AeroSystems celebrated its 10th anniversary in 2015.

Autoclave to OOA

The capacity of the company’s operation in composite aerostructure manufacture is immense. Spirit operates 35 autoclaves to produce some of the largest composite structures in the world, says Linda Cadwell Stancin, Spirit’s director of core structures engineering and technology. Cadwell Stancin points out, for example, that Spirit produces the forward section for the Boeing 787 fuselage and the center section of the Airbus A350 XWB fuselage. It also produces propulsion structures, such as nacelles, with composites, and delivers composite helicopter structures and wing components, such as leading and trailing edges and spoilers. An example of a current large composite structure developed by Spirit is the Airbus A350’s front wing spar.

Although autoclave manufacture is a mainstay of the company’s business, Cadwell Stancin points out that the company isn’t limited to autoclave processing, noting that, “50% of our new contract development is some kind of out-of-autoclave [process].” Spirit, in fact, has always advanced emerging technologies of interest to its customers, including those involving out-of-autoclave (OOA) cure, for which it has investigated most available forms of OOA materials, including prepreg, from Cytec, Toho Tenax, Toray, Albany, Saertex and Hexcel. Further, Spirit has fabricated prototypes and parts using OOA prepregs, thermoplastics, and via the method that prompted CW’s visit to its Prestwick facility, resin infusion.

In the words of Cadwell Stancin, “We know that development for future items has to be more nimble, more creative and significantly less costly than in the past to meet challenging development schedules for the next aeroplane. OOA enables that and helps us serve our customers more effectively.”

Spirit is participating in UK government-sponsored research efforts for Factory of the Future and advanced composites. Cadwell Stancin emphasized that, “Government-sponsored research is really important to success in the aerospace industry.” She further added that, “Early research, below Technology Readiness Level [TRL] 6, significantly benefits from the work of the universities and centers.” Cadwell Stancin specifically credited the National Composites Centre (NCC, Bristol, UK) and the Advanced Manufacturing Research Centre (AMRC, University of Sheffield, UK).

IRIS (Intelligent Resin Infusion System)

One of the most compelling aspects of Spirit’s OOA development work is its own propriety, patented system known as IRIS (Intelligent Resin Infusion System). A detailed examination of IRIS was the centerpiece of CW’s site visit to Spirit’s facility on the south-west coast of Scotland, approximately 50 km to the southwest of Glasgow. Here, Spirit has produced developmental demonstrator wing structures complete with stiffeners, using its IRIS technology, and work is progressing to produce entire wing structures. Crucially, IRIS and associated tooling technology developed by Spirit enables accurate placement of structural supporting features, such as ribs, and, says Cadwell Stancin, gives Spirit the ability to “put the properties exactly where they need to go.”

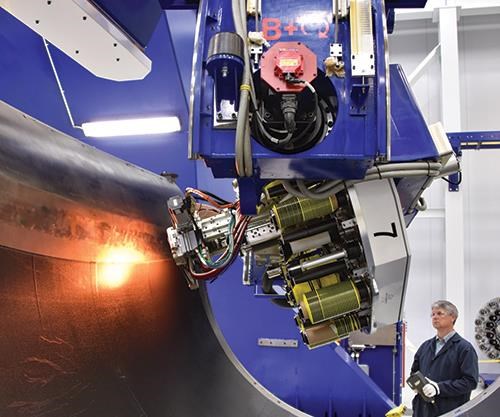

The essential features of IRIS can be seen in Fig. 1, at left. The resin flow media is built directly into cavities in the tooling. David Watson, Spirit’s senior manager at the Advanced Technology Centre at Prestwick, and our guide during the tour, explains that another important feature of IRIS is that cure is not controlled by the direct measurement of temperature by thermocouples, as is the aerospace norm. Instead, strategically placed calorimeters are distributed across the tool surface, located at higher density in critical areas of the part geometry. IRIS, therefore, ensures a more uniform and efficient cure across the entire part.

The IRIS process represents a considerable deviation from the norm in aerospace composites manufacture. The cure cycle is usually rigidly controlled, with long, slow ramp-up and cool-down rates, based on the lowest temperature, slowest thermocouple. This means that thicker areas of the part are adequately cured, and that thin, large areas of parts are cured more than is necessary. IRIS, however, enables zoned tool heating, to put the heat exactly where it’s needed. These features of IRIS have enabled Spirit to accrue significant cost savings in terms of turnaround time, more efficient tooling utilization and an overall reduction in energy use. IRIS is the subject of two separate patents for Spirit.

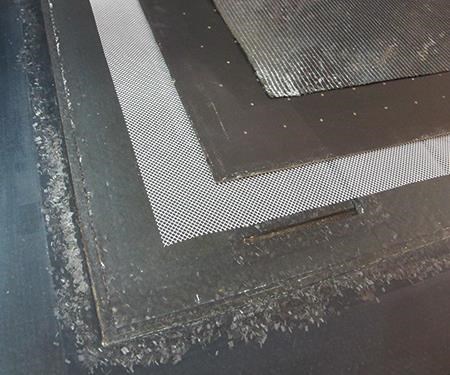

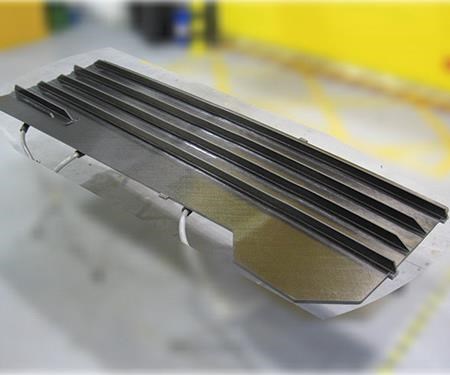

A large composite, upper wing cover demonstrator has been made at Prestwick (see Fig. 2). Watson was able to show CW representative sections of this cover, and what stood out boldly was the overall finished quality of the part. In particular, the stiffening ribs and associated features were very accurately placed, consistently within aerospace geometric standards over the entire part area. Watson also showed a typical photomicrograph of a sectioned spar flange corner (see Fig. 3). The quality of the feature is clear, and fiber wrinkles and other defects that are commonly seen in similar prepreg parts are absent. Clearly, if such quality can be consistently demonstrated in full production, Spirit has taken a big step forward with the IRIS process and its smart approach to tooling.

Architecture, automation and tooling

The whole range of available fibers, of course, can be used in the IRIS process and Spirit uses many of them, where appropriate. However, particularly in large structures used in the most demanding of applications, including wings, Spirit makes wide use of intermediate-modulus carbon fibers. Non-crimp fabrics (NCFs) form the basis of many prototypes. In addition to NCFs, Spirit uses different fabric forms to suit the need in combination with NCF. For example, Spirit has developed, in conjunction with a supplier, 3D woven cleat preforms, which form attachment points for a rib to a wing cover, to incorporate into layups. Spirit also uses braided forms and incorporates stitching into its large preforms.

To date, NCF layups have mostly been carried out by hand. But Watson acknowledges, “We have to find a way to automate the whole process,” Unlike the tows and tapes used with automatic fiber placement (AFP) and automatic tape laying (ATL), NCF layers cannot be laid side by side. “You can’t have multiple joints in NCF. You have to deposit the whole tape width.” Watson likens it to “rolling out a carpet.” Toward that end, Spirit has investigated a number of automated options from a variety of suppliers.

Hand-in-hand with IRIS is Spirit’s new patented and trademarked tooling approach, which it calls Inflexion. Co-invented with Spintech LLC (Xenia, OH, US), Inflexion features tool elements made from shape memory polymer (SMP, see “Learn More”). Watson explains that the SMP softens slightly during the cure cycle and works somewhat like a vacuum bag, helping with the consolidation of the part laminate. With conventional tooling, it is often very difficult to remove the internal tooling or mandrel of the part supporting the internal features of a hollow structure after cure. The ability to warm the structure and soften the SMP tooling, rendering it slightly elastic, helps to facilitate part removal from the tooling.

Out-of-autoclave prepreg process development

OOA-cured composite materials offer significant affordability and fabrication-flexibility advantages over traditional autoclave-cured materials, but their use on modern rotorcraft structures poses unique challenges. The need for extremely lightweight structures on rotorcraft fuselages has been met by Spirit through the use of composite skin panels that feature nonmetallic honeycomb core bonded to very thin composite facesheets.

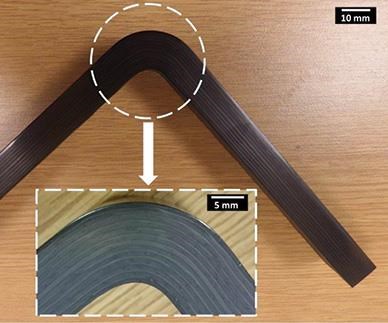

For OOA processing of prepreg, vacuum bagging is critical to success, and there are a host of skills that technicians must master to prepare layups well for oven curing. The autoclave, by comparison, is a more forgiving device. At Prestwick, Watson was able to show some of the development Spirit had done with Cytec’s MTM44-1 prepreg on traditional flanged honeycomb panels. An example photomicrograph of a honeycomb ramp flange interface can be seen in Fig. 4. The quality of the interface can be seen to be at least as good, if not better than, that achieved in the autoclave.

Spirit reported that when sandwich panels are constructed under atmospheric pressure, some film adhesives exhibit a tendency to foam, creating porosity in the core-to-cell wall fillets that reduces shear strength. The propensity to foam is a function of the adhesive itself and the material and form of the carrier. OOA adhesives are available, and Spirit scientists carefully selected products to match the cure cycle of the facesheet resin system to eliminate strength reductions in sandwich panels caused by adhesive foaming.

Also, if not properly bagged and cured, some OOA materials have slightly higher porosity levels that might make OOA materials more susceptible to moisture ingress than autoclave-cured systems. If an impact event causes small through-the-thickness microcracks in the resin to link with the small air pockets, a moisture path through the facesheet thickness could result. Over time, due to capillary action, moisture can be drawn into the honeycomb cells. This moisture build-up, in turn, can further degrade the sandwich panel’s overall strength over time due to freeze/thaw cycles and pressure changes. Spirit has worked with material suppliers and its OEM customers and their suppliers to optimize the curing process for OOA sandwich constructions.

Spirit AeroSystems credits close coordination with customers and material suppliers for much of what has resulted in its high-quality OOA sandwich panels that now exhibit quality equal to that of conventional autoclave-cured panels. The use of non-foaming adhesives has significantly improved the quality of co-bonded and co-cured structures. A typical honeycomb sandwich panel made by Spirit can be seen in Fig. 5.

Notably, OOA resin systems provide other advantages, particularly in the area of repair and rework because bonded repairs can be made outside of the autoclave under vacuum bag only, with local heating. Damaged parts potentially can be cheaply and easily repaired to their full blueprint strength. Toray Industries (Tokyo, Japan) is collaborating with Spirit in testing composite formulations for OOA repairs.

Going forward

“Cure time is a bottleneck for high-rate production,” concludes Cadwell Stancin. In the future, materials must cure much faster and “material chemistries should be improved to make sure resin flows in a controlled manner through complex architectures and the material systems control knock-down due to variability of fiber volume fraction throughout the structure.”

Spirit AeroSystems is constantly evaluating emerging OOA systems and providing their input back to suppliers in order to improve those systems.

As more OOA systems become available and the processes become robust, Cadwell Stancin expects more OOA parts to be developed: “For Spirit AeroSystems, the move to OOA is not a question of if, but only one of when.”

Albany Engineered Composites Inc.

Toray Carbon Fibers Europe

Related Content

Formable, reusable tooling achieves complex composite parts

CAMX 2024: Hawthorn Composites is displaying an inner and outer tail boom and a multi-chamber composite trailing edge control surface, enabled via its Smart Tooling solution.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreDLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreRead Next

An out-of-autoclave progress report

CW Conferences director Scott Stephenson recalls Dale Brosius’ update on Quickstep’s out-of-autoclave work for the F-35 program.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More