Structural armor or armored structures?

Either way, antiballistics engineers seek structural integrity and ballistic deterrence from a single design.

Share

Until recently, there were good antiballistic materials and good structural materials, and — materials engineers and end-users have usually assumed — never the twain shall meet. For example, a fiber reinforcement and matrix must, by design, capture and stop projectiles. Antiballistic materials, reinforced with aramid or various types of polyolefin fibers with superior elongation-to-break characteristics, absorb and dissipate the energy of a high-velocity impact through a number of energy-absorbing mechanisms. These include spall formation, tensile fiber failure of primary yarns, fiber debonding, fiber pullout and interlayer delamination. Unfortunately, each is a failure mechanism that all good structural materials are supposed to avoid. Carbon-fiber/epoxy, one of the best structural materials available due to carbon’s stiffness, high tensile strength and extremely low elongation, is therefore a poor performer from a ballistics standpoint. “When a high-speed projectile strikes a carbon-fiber panel, that point of impact becomes a localized point of failure,” says David Fecko, new business development manager at AGY Holding Corp. (Aiken, S.C.).

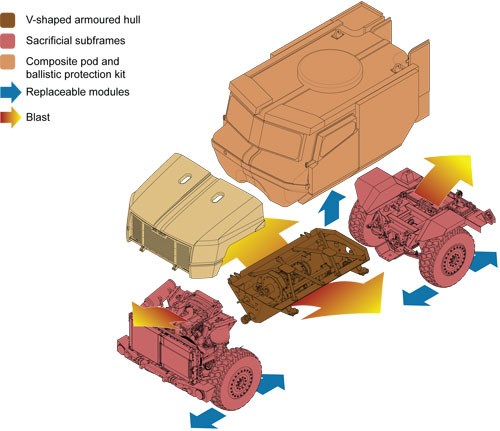

This difference is by no means trivial. In practical terms, it means that structures and the armor for those structures often are engineered and produced separately: Ground vehicles and stationary shelters are designed and built conventionally. Then armor is added (often literally, in kit form) at extra expense. Add-on armor, of course, contributes significantly to overall weight. In the case of vehicles, there is a corresponding reduction in mobility, maneuverability and fuel efficiency.

This dichotomy is changing, however, as engineers take steps to bridge the performance gap with new materials and hybrid constructions that meet multiple performance demands while increasing manufacturing efficiency and reducing cost. The goal is a finished composite component that has sufficient structural strength for the intended use and exhibits the required antiballistic properties.

Armor-worthy structural glass

One candidate for a viable structural antiballistic material is S-glass fiber, which has taken a significant leap into the limelight in a new all-terrain military vehicle for the U.K.’s Light Protected Patrol Vehicle (LPPV) Program (opening photo). The SPV400 is designed for maximum roadside-blast protection, says Nick Ames, managing director of SPV400 manufacturer Supacat (Devon, U.K.), who claims that its construction offers LPPV “protection levels far beyond those [currently] available in other vehicles in the 7.5-ton class.” The vehicle incorporates a V-shaped armored hull for underside protection and an all-composite crew pod made from woven-glass prepreg panels. Supacat has formed an alliance agreement with NP Aerospace (Coventry, U.K.) to supply armor for the vehicle. AGY supplies its proprietary S-2 Glass for the composite panels.

Although AGY’s S-2 Glass product is armor capable, glass fiber generally outweighs the aramids and other thermoplastic fibers classically employed in armor applications. For that reason, AGY introduced Featherlight S-2 Glass fiber to the market in 2008. The fiber was developed in response to the U.S. military’s initiative to build lighter vehicles with better structural and antiballistic performance. The new fiber has a 5 to 10 percent greater tensile strength than conventional S-2 Glass. Therefore, Featherlight can be used either to make composite armor of the same weight with improved ballistic performance, or to make lighter armor with identical ballistic properties. Featherlight is the result of changes to the fiber architecture, namely smaller diameter filaments with more fibers per bundle.

Fecko believes there is potential for greater improvement. During the past four years, in fact, AGY and the Army Research Laboratory (ARL, Adelphi, Md.) have collaborated to investigate ways the performance properties of S-2 Glass might be modified, using sizing technology developed by ARL. The purpose of the project is to maximize the structural performance of armor panels during low-strain conditions (e.g., typical road vibrations) and optimize energy absorption during high-strain conditions (e.g., ballistic impact). Researchers found that ARL’s multicomponent sizing imparts higher structural integrity to an S-2 Glass/epoxy composite while doubling the Mode II (in shear) fracture toughness of the system, without damaging fibers or increasing moisture uptake. Further, drop-tower testing showed that the damaged area of the composite was greatly reduced when compared to samples made with traditional sizing.

Although the sizing is not yet commercial, AGY’s Fecko says the research results are promising enough to compel “a full-blown research project to launch the next-generation S-glass fiber.” Fecko says the unique chemistry of S-2 Glass (its higher silica content, in particular) imparts higher tensile and compressive strength, which makes it ideal for structural applications, but it is not always the best choice for ballistic protection. He suggests, however, that there might be ways to change the glass chemistry to enhance antiballistic performance, yet it retains some features that make it attractive for structural hard armor. Beyond modifications to chemistry, AGY also will investigate the fiber/matrix interface, fabric architecture and other factors that have an impact on performance.

Elsewhere on the materials front, Milliken & Co.’s (Spartanburg, S.C.) new version of its Tegris self-reinforced polypropylene (PP) composite, trademarked Tegris LM, shows promise for structural antiballistic applications when combined with other fibers. Tegris is based on the company’s (pat. pend.) PURE technology, a three-layer coextruded tape consisting of a polymer skin of PP fibers with a relatively low melting point, a highly-drawn PP fiber core and another layer of low-melt PP skin. Drawing axially orients the core fibers, creating a highly reinforcing material that acts, in a composite, like glass fiber, but contributes much less weight. Typically, Tegris yarn is woven into fabrics and consolidated into sheets that subsequently are thermoformed or compression molded. The low-melting skins become the polymer matrix when heat sufficient to melt the sheath but not hot enough to melt the fiber core is applied during the molding process. Milliken recently shipped 20,000 Tegris armor kits for vehicles deployed in Iraq and Afghanistan. Predominantly flat panel systems for spall liners, the kits are used, for the most part, to retrofit vehicles for enhanced protection against Explosively Formed Projectiles (EFPs).

In the standard Tegris product, matrix formation is initiated at ~300°F/~149°C and pressures of 300 psi and greater. But Tegris LM can be molded at temperatures ranging from 225°F to 300°F (107°C to 149°C) and pressures from as low as 30 psi to a high of 300 psi. This broader processing window makes Tegris LM compatible with autoclave processing and infusion molding, which enhances, in turn, the material’s suitability for comolding with carbon, aramid and/or polyethylene fiber forms to create hybrid structures that combine good structural and ballistic properties.

Eric Brockman, Milliken’s national sales manager, says the impetus for Tegris LM was customer requests. “When we first introduced the Tegris product, you basically had to compression mold to make a part,” says Brockman. “We heard, over and over again, ‘Great material. Love that it’s fairly structural. But if you could broaden the processing window it would increase the opportunity to use the material.’” Milliken already has demonstrated and qualified Tegris LM for one military body armor application and has submitted the material for two other applications.

Brockman allows that Tegris LM is unlikely to be the only product used in an armor design, but he contends that used in conjunction with other antiballistic fibers, it can save weight, control delamination and reduce cost. In a typical body armor design, a layer of Tegris LM can replace the layer of Kevlar- or polyethylene-fiber-reinforced polymer immediately behind the ceramic strike face to support the ceramic and help control back-face deformation. Brockman says testing shows that this configuration can improve multi-hit performance at a lower cost.

Milliken is looking for Tegris LM to expand the company’s presence in body armor, including products with complex geometries, such as combat helmets. Although the U.S. military’s new Enhanced Combat Helmet (ECH) will be a hybrid construction made of a carbon-fiber shell or cage overmolded with high-molecular-weight polyethylene (see sidebar at the end of this article), Brockman believes Tegris could find a place in future helmet designs. The ECH’s carbon-fiber shell is needed to add structural integrity and control ear-to-ear compression or dynamic deflection, but he suggests that future helmets could incorporate a layer of Tegris and eliminate the need for more costly fibers. “If you took the playing field of materials before Tegris, you had a group [that] was structural and included glass and carbon, then you had an area of antiballistic-type materials, such as brands of ultrahigh-molecular-weight polyethylene [UHMWPE], and aramid materials that were weak in terms of structural performance,” notes Brockman. “Tegris fits the niche between these materials.”

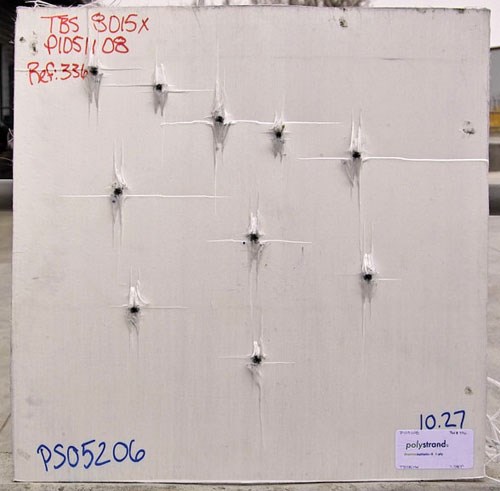

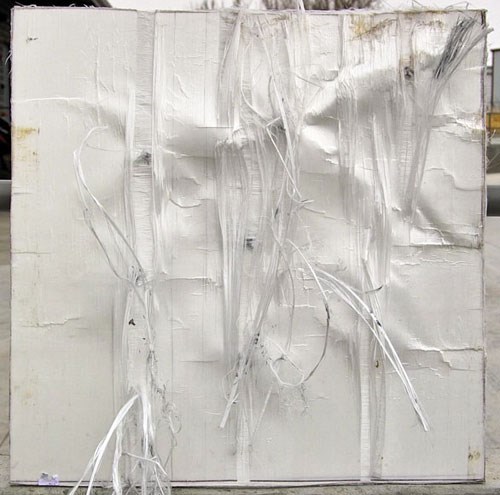

Polystrand Inc. (Montrose, Colo.) has focused on the integration of multiple materials in a single hybrid design. The company received formal approval on a patent for hybrid thermoplastic composite ballistic panels (Patent No. U.S. 7,598,185 B2). Polystrand is best known for its ThermoBallistic family of materials, which combine continuous strands of glass or aramid fibers with proprietary polypropylene or polyethylene fibers in the form of sheets or layered tape laminates. The new hybrid panel combines layers of S-glass, E-glass and aramid fibers. ThermoBallistic reinforcing tapes are used in a 0°/90° cross-ply layup that is subsequently compression molded at 360°F/182°C with pressures as low as 100 psi/6.89 bar. Polystrand president Ed Pilpel says the hybrid panel fulfills antiballistic and structural functions: “Our testing ... showed this construction could effectively be used on future military vehicle platforms to reduce costs.”

Similarly, Norplex-Micarta (Postville, Iowa), manufactures laminated panels as large as 4 ft by 9 ft (1.2m by 2.7m), consisting of a number of different layers of materials that are placed in a press and consolidated in a single step under heat and pressure. A typical construction might consist of an inner layer of UHMWPE — either Honeywell Advanced Fibers and Composites Spectra or DSM’s (Geleen, The Netherlands) Dyneema — followed by a layer of infused, semicured glass-fiber mat, followed by an outer ceramic layer. The inner thermoplastic layer acts as a spall liner, the impregnated glass fiber provides structural strength and the ceramic outer adds protection from armor-piercing rounds, says Alan Johnson, director of business development at Norplex-Micarta. The individual layers are consolidated and bonded with a proprietary epoxy adhesive system. Pressures used to consolidate the panels depend on the types of individual layers in the construction. Panels containing just glass fiber and ceramics can be consolidated at pressures as low as 250 psi/17.24 bar, while pressures as high as 3,000 psi/206.84 bar are used to consolidate panels that also include the inner thermoplastic layer. Norplex-Micarta also has developed a grout that reduces damage in the event of a strike. Typically, when a round hits, it not only damages the ceramic tile it strikes but the surrounding tiles as well, says Johnson. “This grouting material ... surrounds each individual tile so when a round hits it doesn’t shatter the adjacent tiles.”

Materials & intangibles drive change

Two factors have coalesced to accelerate change and hasten the commercialization of hybrid constructions over the past decade. First, advances in materials other than fibers have led to increased processing flexibility and have provided manufacturers with more manufacturing options. Dana Granville, senior materials engineer at the ARL’s Weapons and Materials Research Directorate (Aberdeen, Md.), says improvements in the quality of low-viscosity vinyl esters and epoxies have played a crucial role in the growing use of out-of-autoclave processes, such as resin transfer molding (RTM) and vacuum-assisted RTM (VARTM), for antiballistic applications. “When we first started testing composite materials,” he recalls, “whenever you would add anything to an epoxy to reduce viscosity, say, for a pultrusion application, we always sacrificed performance.” Granville also says advances in sizing technology, such as the AGY/ARL effort discussed earlier, are enhancing antiballistic composites.

A second factor has been a post-9/11 emphasis on lightweighting and cost reduction as testing under real-world conditions (e.g., in Iraq and Afghanistan) exposed limitations of then state-of-the-art hard- and soft-armor, providing the impetus for end-users and suppliers to seek and fund radical change. “You need drivers to push the industry to come up with technology that will advance the use of composites in ballistics design,” says Lori Wagner, armor industry technical leader at Honeywell Advanced Fibers and Composites (Colonial Heights, Va.). Wagner says that at one time, ballistics engineers considered “a modification of the type of water-repellent treatment, or going from a 24x24 plain weave to a 25x25 plain weave” to be a significant change to body armor construction. Now, she believes, the industry is becoming less conservative, citing for example a manufacturer of body armor for law enforcement that switched its entire line from woven fabric, once considered the standard, to Honeywell’s unidirectional Spectra Shield composite after testing showed the latter would improve performance. Spectra gel-spun extended-chain polyethylene fibers, according to Honeywell, have one of the highest strength-to-weight ratios among man-made fibers.

Lightweighting has been a U.S. Army research priority since the 2003 launch of a formal program dedicated to reducing land vehicle mass of Future Combat Systems (FCS) manned ground vehicles (MGVs). Overseen by ARL, the FCS program was to create a family of lighter, faster, more flexible vehicles based on a common tracked-vehicle chassis. The original directive called for development of three generations of composite armor, culminating in panels that would protect the 27-ton MGV in 2015. This third-generation armor was to have same antiballistic performance as then current armor but at 25 percent less weight. In April 2009, the Pentagon canceled the MGV, rolling the FCS initiative into a new effort, the Army Brigade Combat Team Modernization Program. Shortly thereafter, the army launched the Ground Combat Vehicle (GCV) program, seeking a replacement for the Bradley Fighting Vehicle. The GCV program calls for a 50- to 70-ton vehicle with the underbelly protection of a mine-resistant, ambush-protected (MRAP) vehicle and better side resistance than a Bradley. Defense firms submitted proposals for the first phase of the GCV in May of this year, and program officials are expected to award as many as three development contracts this month. Although researchers are still working out GCV design details, lightweighting appears to be the prime objective: Army chief of staff Gen. George Casey recently said that the GCV needs to be closer to the weight of a MRAP (about 23 tons).

Cost reduction is more important than ever before because today’s armor solutions are more complex. “A typical armor construction today is a combination of materials — steel, ceramic and composites,” says Granville. The principal question is how to combine and bond them cost-effectively, yet maximize performance. Consequently, there is greater openness to alternative methods. Granville recalls a method that arose out of an ARL effort, with collaborator United Defense Industries (now BAE Systems, Monroe, N.C.), to develop a composite hull for a now-defunct vehicle platform. Granville says the program’s purpose was to demonstrate a 50 to 60 percent reduction in the cost to manufacture thick-section, multifunctional armor. Although the program was not completed, some of its technology could be applicable to future ground combat vehicles. The program envisioned automatic delivery of a vinyl ester resin, or the A and B components of an epoxy, to infuse preforms in a low-pressure molding process. A network of programmed sensors monitored the resin flow front simultaneously at multiple locations and automatically controlled injection gating as the front progressed. Granville contends that preforms could be a key to cost control: “The cost of a fiber preform can be less than two times the cost of the raw material, which is a lot cheaper than ... tape laying a part with those materials.”

More change to come

Pushed by demands for better performing and more cost-effective armor solutions, the quest for new multifunctional materials is certain to continue. “There are a lot of different materials out there,” observes Honeywell’s Wagner, “and we are still in our infancy of understanding the way they can be used in systems to exploit the advantages each might have.” Manufacturers’ willingness to consider not only a broader array of fibers but also a greater variety of fabrication processes should ensure a lively period of innovation and profitable application of composites in antiballistic products.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreRead Next

Antiballistics: Composites in the cross hairs

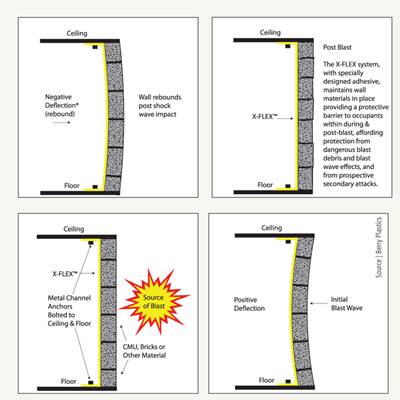

An increasing quantity and variety of fiber/polymer solutions are stopping bullets and blast debris in armored ground vehicles and stationary structures.

Read More