Techonologies for UV curing of composite laminates demonstrated

Racing go-kart project demonstrates advances in UV processing of composites.

A one-part resin that requires no catalyst or mixing, has an indefinite pot life, and cures in seconds with minimal emissions when exposed to ultraviolet (UV) light - it sounds too good to be true. So why aren't more composites fabricators using UV curing methods, which have been in existence since the beginning of fiberglass composites and used by such pioneers as Hobie Adler for his surfboards?

UV cure is certainly an important and widely used surface technology for coatings, printing inks, computer disk production, adhesives and other applications, in industries characterized by fast production line speeds that apply very thin layers of materials on flat substrates. In the last few years, UV curing has found limited use in several composites applications: Pultruded profiles and panels for decorative residential doors (see CT February 2002, p. 33); filament-wound sporting goods, where each ply is cured "on the fly" during the winding process, as demonstrated several years ago by Spencer Composites Corp. (Sacramento, Calif., U.S.A.); and cured-in-place pipe (CIPP) applications, where the shape and thickness of the laminate is consistent and relatively thin. More recently, the outer gel coat layer on filament-wound pressure tanks has been UV cured, in a process developed by Entec Composite Machines Inc. (Salt Lake City, Utah, U.S.A.). Yet, it hasn't been widely adopted in the composites industry, particularly for hand layup of parts with more complex shapes, for several reasons. "UV is great for parts with uniform shape and thickness, but complex shapes with variable laminate thickness make cure tricky," says Dr. Tom Folda of AOC Resins (Collierville, Tenn., U.S.A.), a supplier of UV cure resins. "You have to invest time and money to optimize all the variables like lamp intensity, position, the resin mix and so forth."

First, UV energy can only penetrate optically transparent material, which includes glass fiber, and only to a maximum depth of between 13 mm and 19 mm (0.5 inch to 0.75 inch) in one shot. Carbon fiber and aramid fiber, which are opaque, can be used if each laminate ply is cured separately as in the filament winding example cited above. Typical resin fillers like calcium carbonate can't be used, since they prevent full penetration of the light. Cored composites are possible, if the core is transparent, like polypropylene honeycomb, or if the outer skin is layed up and cured first, followed by placement of a solid core, with the inner skin layed up and cured in a separate step. To cure effectively, the light must reach the entire part, so shadows caused by the part curvature or by fixtures, such as vacuum bag hoses or fittings, have to be eliminated.

Second, the process cures the laminate from the top down, so the cured surface prevents styrene emissions, a plus from an environmental standpoint. The quick surface cure does not trap voids within the laminate, says Mark Livesay of Sunrez Corp. (El Cajon, Calif., U.S.A.), the largest UV resin supplier, because a high degree of molecular cross-linking is achieved very quickly. But, if too much radiant energy is directed at the laminate and the cure proceeds downward too quickly, styrene in the resin can be driven down through the laminate to emerge on the inner (mold) face, causing pinholes and poor surface quality. Further, the higher the percentage of photoinitiator catalyst additive in the resin, the greater the cure speed and depth, yet the additive can adversely affect laminate mechanical properties. In other words, several variables including lamp wavelength, choice of resin, amount of catalyst filler, distance from lamp to laminate surface and exposure duration have to be carefully integrated, to achieve the best results.

A third consideration that has held UV curing back is the capital cost of the lights that are required. Because of the amount of energy the lights produce, lamps are expensive. In addition, the lamps are somewhat fragile and can be cumbersome to move around, to ensure complete cure of irregularly shaped parts.

Paul Mills of UV Powerhouse (Strongsville, Ohio, U.S.A.) is a member of RadTech International North America (Chevy Chase, Md., U.S.A.), an advocacy group that promotes UV curing for a wide variety of industries. Mills founded the organization's plastics focus group and believes that ultimately composites and UV cure is a good fit for many applications, from the standpoint of reduced cycle times and environmental benefits.

"The cost of the UV lamps and the resins has certainly been a factor in limited adoption so far, but more importantly, the larger companies haven't yet embraced the technology," states Mills. "In my opinion, The Environmental Protection Agency's new regulations for air emissions will be a driver for wider adoption of UV cure for composites."

Team UV Redux

Several RadTech members recently funded the fabrication of a racing go-kart to demonstrate the advantages of UV technology for composites. The go-kart project was a follow-up to a previous demonstration effort headed by Mills in 1999, dubbed "Team UV," in which a full-scale fiberglass-bodied racecar was built with UV-curing technology. But the car was somewhat difficult to transport to trade shows and events, and advances in the technology made a new, more portable demonstration project timely. Supplier companies agreed to share the cost of producing the go-kart, and Mills was able to round up volunteers to get the work done. Definitely not a "kiddie car," the four-wheeled vehicle is a fast racing kart of the type driven by both teenagers and adults at racing venues, and is powered by an 8-hp, four-stroke Briggs and Stratton engine.

"This was obviously a one-off effort, but it demonstrates that the processes and materials are viable production technologies," states Mills. "It was a lot of fun to do, and we ended up with a part that draws attention because it's functional and good-looking. It was important to us that all of the products used are available for commercial production."

An off-the-shelf tubular aluminum chassis was purchased and a stock body from Rossiter Mfg. Co. (Edgewater, Fla., U.S.A.), the maker of Lightning Light kart bodies, was used as a plug. From it, a female fiberglass layup mold was created, using traditional peroxide-cure polyester and fiberglass tooling cloth

With the female mold ready and prepared with mold release, 0/90 woven E-glass was layed in the mold and wet out with the UV-curable polyester resin, formulated by Sunrez by adding fast-acting photoinitiators, similar to those originally developed in the mid-1970s by BASF (Ludwigschafen, Germany). Because photoinitiators can be introduced to the resin like any other additive, vinyl ester and epoxy resins can be UV-cured as well. When radiant energy (i.e., the UV light) cleaves an atom from the photoinitiator molecule, a free radical is created that acts similarly to a peroxide-type catalyst, linking with the resin molecules and causing rapid crosslinking. Different manufacturers' photoinitiators are designed to act in the presence of a specific UV (or visible) light absorption spectrum (discussed below).

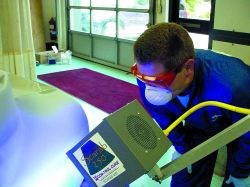

The one-part resin required no mixing and pot life and layup times were unlimited, as the resin is unaffected by standard incandescent light. And, excess resin was collected and put back in the container for reuse. Although sprayup wasn't employed on the kart project, chopper guns don't require repeated solvent cleanup, because there's no cure reaction until UV light exposure. Once the uncored, four-ply, solid 0.2-inch thick laminate layup was complete, the mold was vacuum-bagged with a clear nylon film to help consolidate the laminate, then exposed to UV light to cure, using lamps manufactured by UV Process Supply (Chicago, Ill., U.S.A.).

The Light Stuff

By way of background, three light parameters are required for successful UV cure: 1) the correct wavelength, 2) sufficient brightness or radiant energy (referred to in the UV cure industry as "peak irradiance") and 3) the appropriate "dosage," or the amount of energy delivered to the part over time. First, the issue of wavelength: although UV light is often referred to as a single entity, practitioners typically divide the UV spectrum into discrete chunks, classified as UV-A, UV-B or UV-C, depending on wavelength. The "A" category contains the longest wavelengths (ranging from about 315 to 400 nanometers (nm), the closest to visible light) and C is the shortest (between 200 and 280 nm). The shorter the wavelength, the more powerful the energy, but longer wavelengths are better at penetrating the laminate and are not absorbed as easily by the glass reinforcement.

"UV is in a state of evolution," observes Mills. "Processes once reserved for high-speed industrial production - where the lamps are often sealed in locations where workers don't come in contact with them - is now finding its way into fiberglass shops. But that requires a re-thinking of the equipment needed from a safety, cost and ease-of-use perspective."

Mills refers to the potential for deleterious health effects, like skin and eye irritation, from unshielded lamps. UV-A wavelengths, preferred from a processing standpoint, also are better from a safety standpoint, because they pose a lower health risk in the type of fabrication environment common in composites, where portable lamps typically have to be moved around a large part.

Traditionally, two types of UV light sources have been used, either medium pressure mercury vapor arc lamps or microwave-based lamps. Three general types of lamps are available, depending on the project needs. The most common is a flood light, for curing large areas at relatively low to moderate brightness or intensity. Focal beam lamps are those most commonly used for high-speed production line curing, like pultrusion, and have very high brightness for adequate cure as the parts move by. Finally, small spot source lights are used for curing a very limited area, such as a patch or other repair. Both flood lights and spot source lights were used on the go-kart project.

"Traditional lamps are rather inefficient and produce lots of visible light and infrared (heat) energy along with UV, plus the power demand is high," says UV Process Supply's Stephen Siegel. "A household fluorescent bulb produces about 1 watt of energy per linear inch. In contrast, a UV-A curing bulb produces 400 to 600 watts per linear inch, at very high voltage."

To increase efficiency and safety, the lamp is fitted with a glass filter, so that most of the visible light and the UV-B and UV-C components are filtered out, leaving the UV-A. Heat produced by lamp infrared emissions has been managed by means of fans or other cooling systems.

Lamp Innovation

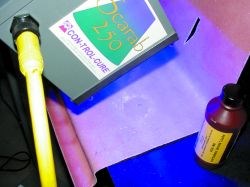

Siegel describes a new type of UV lamp that his company has developed, made up of arrays of light emitting diodes (LEDs) that emit a narrower band of UV wavelengths, between 385 and 415 nm. Voltage requirements for the LED lamps are significantly lower than traditional lamps and no filters are needed, since the lamp produces light only in the desired UV wavelengths. While the lamps don't produce heat, the diode chips do get hot, says Siegel, so the chips are mounted within a conductive polymer material with a small fan to manage temperature. Lamps last as long as 50,000 hours, says Siegel, as compared to the 500- to 1,000-hour life of traditional mercury vapor lamps, and because they are mercury-free, they present no disposal hazard. Most importantly, LED lamps are lightweight, tough and very portable (in contrast to relatively fragile glass lamps) and easily can be set up around a mold for cure.

"The trick is in creating a lamp that fits the part geometry," says Siegel. "We can arrange the LEDs in any configuration - either in round pods or linearly - to find the the best configuration to suit the customer's part shape." Making the lamp array conform to the surface of the mold will solve a very difficult problem in terms of production efficiency. The distance from the lamp to the curing surface is critical to curing effectiveness and speed, so with irregular parts, curing time had to be lengthened to make sure the entire part laminate cured properly.

To compare the LED lamps with traditional mercury vapor lamps, segments of the go-kart were cured with lamps of both types, supplied by UV Process Supply. Both types cured the glass laminate satisfactorily, but UV Supply's higher-powered Scarab mercury arc lamps got the job done faster, taking about four minutes. The LED lamps accomplished cure in about eight minutes, says Mills, noting that room-temperature cure of a non-UV resin takes several hours.

"The LED lamps are evolving rapidly, in the same way that computer microprocessors changed a few years ago," says Siegel. "New chips are now 10 times as powerful, so we fully expect to narrow the gap with arc lamps in the very near future."

UV Materials for Repair

The cured laminate was deliberately damaged in a few locations, in order to allow the team to demonstrate patch-and-repair techniques, using product supplied by Sunrez, a UV-curable prepreg with the brand name SunPreg, designed for structural repair, and a body putty. The glass mat or woven fabric is pre-impregnated with photoinitiator-dosed unsaturated polyester resin, then placed between polyvinyl acetate (PVA) films and stored until ready to use. In combination with the Sunrez body putty, patches were applied and faired, then cured in less than a minute with a small, spot UV light source aimed directly at the repaired area. The go-kart body was painted with a new UV-curable primer/surfacer just released by PPG Industries (Pittsburgh, Pa., U.S.A.). The base coat is ready in just minutes, rather than having to wait hours or even days for the surface to set.

Mills points out that because each UV cure resin or coating supplier formulates slightly different products that are tailored to specific absorption spectra, in essence a unique "processing window" exists for each product. RadTech is striving for a "forgiving" window for composites fabricators, to ensure success even if resin and lamp characteristics vary.

"It's critical that the fabricator talk to both the resin supplier and the lamp supplier, to make sure the two are compatible and that the cure will proceed properly," says Mills. "While UV is an off-the-shelf product in other industries, we don't want to see anybody fail at this technology in composites, before it's given a chance."

Related Content

Braskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read More3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More