The making of the BMW i3

CompositesWorld's tour of the BMW i3 manufacturing and assembly plant in Leipzig, Germany, offers a glimpse of one possible future of automotive production.

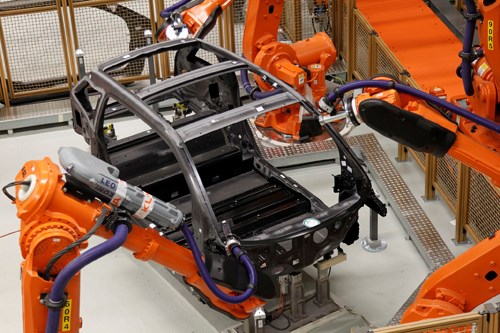

The Life Module of the BMW i3 all-electric is comprised of resin transfer molded carbon fiber composite structures that are assembled via robotics at the company's manufacturing and assembly plant in Leipzig, Germany.

The composites industry is full of innovators and creative thinkers, people who move the industry forward incrementally toward greater efficiencies, lower costs and higher quality. But the big material and process leaps the composites community has seen throughout its history have required more than individual expertise. The Chevrolet Corvette or The Boeing Co.’s 787 Dreamliner, for example, is the product of a massive, collective corporate commitment, backed by a capital investment as big, bold and precedent-setting as the envisioned product — a commitment that, to some composites pessimists, appears reckless, hasty, ill-timed and doomed.

Corporate trailblazers are rare, and rarely attempt such leaps without a good command of the materials, processes and technologies required to achieve success. Even so, the risk of doom is real, and redoubles with the size of the enterprise. Missed deadlines and technical setbacks are all the more embarrassing for being so public — and inevitably exploited by naysayers. But at the end of what is, at best, a colossal controlled experiment is the honor and recognition as the first to reach a bold and audacious goal.

Onto this less-traveled corporate road the BMW Group steered when, in 2009, it elected to manufacture an all-electric, four-door passenger car using carbon fiber composites. Originally denoted the MegaCity Vehicle, the commuter car now known as the i3 is designed primarily for urban driving and can travel about 100 miles/160 km on a single charge.

As is widely known by now, the i3 features two primary structures, the aluminum Drive Module – which incorporates the powertrain, chassis, battery, and structural and crash functions – and the Life Module (passenger cell), made from carbon fiber composites. The latter is capped by a composite roof made with recycled carbon fiber, and features a spare but comfortable interior that also incorporates recycled materials and other composites made with natural fiber reinforcements.

We were invited in March to visit the i3 manufacturing and assembly plant in Leipzig, Germany and was offered a chance to see, firsthand, the materials and technologies employed in the creation of this unique vehicle. You will find, in the June issue of Composites Technology magazine, a full report on the facility, materials and processes.

In the meantime, some highlights and impressions from the tour:

- BMW, as might be expected, exerts strict control over the quality of carbon fiber produced and woven for the i3, starting at the SGL Automotive Carbon Fibers plant in Moses Lake, Wash., USA.

- Process control of the resin transfer molding (RTM) process used to make the carbon fiber structures for the Life Module is carefully managed. BMW uses, in Leipzig, seven Schuler presses for RTM, with two KraussMaffei RTM injection units on each press.

- BMW clearly is looking for opportunities to speed up its RTM process, reduce carbon fiber scrap rates and minimize resin usage. Thermoplastics are on the radar.

- The roof of the i3 makes creative use of carbon fiber scrap with the applicaiton of a stitched, nonwoven carbon fiber fabric made by SGL Group.

- Assembly of the Life Module — fully automated by 173 fully articulating ABB robots — is impressive. Only adhesive bonding is used, with no mechanical fasteners.

- BMW, when we visited, was making 70 i3 vehicles per day, which BMW says is on par with expectations — and expected to grow. With the i8 sports car (also with a carbon fiber Life Module) about to start production, the company's RTM throughput will be well tested.

- Driving the i3 is fun (see below image). It's smooth, peppy, quiet and responsive.

CompositesWorld conferences director Scott Stephenson (left) with editor Jeff Sloan (right) in front of the BMW i3 they drove while visiting the BMW Group manufacturing and assembly plant in Leipzig, Germany.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More