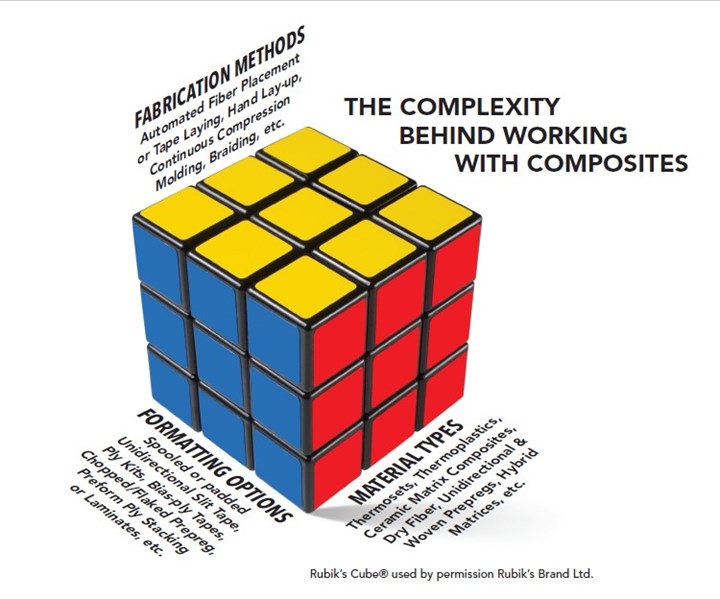

The Rubik’s Cube of working efficiently with different composite materials

Each member of an aerospace OEM’s supply chain works on a different side of the project, ultimately driving toward the same goal: a better composite-intensive aircraft.

Share

Source | Web Industries Inc., with permission from Rubik’s Brand Ltd.

In the race to scale up production to meet commercial aircraft demand, there is no single way to make the best airplane. As aerospace OEMs consider all of their material and processing options, they will continue to find innovative applications for both thermoset (TS) and thermoplastic composites (TPC), not to mention other choices such as dry carbon fiber fabrics and ceramic matrix composites (CMC).

Determining the optimal combinations of materials and processes to build each part, with the required performance and quality, and at the lowest total cost of acquisition (TCA), can be like solving a Rubik’s Cube. Each supply chain partner collaborates with the OEM to align a different side of the cube, with the overall goal of delivering a safe, high-performing, fuel-efficient, comfortable aircraft to the airline, on time and profitably.

Paradigms are constantly shifting as advanced materials and manufacturing techniques evolve. For every aircraft component and part — be it a wing, fuselage, stringer, interior part or engine — there is a cascading set of considerations. What materials are viable for the application? What are the different ways it can it be formatted — for example, as pad plies, spooled slit tape, chopped flake or bias ply? What layup technology is compatible with the formatted material — such as hand layup, robotic layup (in the form of automated tape or fiber placement), preforms or closed compression molding?

Each material and process (M&P) path brings exciting possibilities to the table. Ceramic matrix composites offer the ability to replace metals in high-temperature applications. Thermoplastics are garnering a lot of interest with their recyclability, weldability, fast processing and overall material handling simplicity. They remain stable at room temperature and aren’t as susceptible to environmental contaminants in the workplace as thermoset materials. Dry fabrics also give manufacturers freedom from refrigerated storage and open additional processing options. And, of course, thermosets continue to provide a tried-and-true solution for high-quality, consistent part formation — with well-established costs and proven scalability.

Leveraging core competencies

One could argue that excellent execution is as important as the chosen M&P path itself. After all, it does no good to save cycle time by using an out-of-autoclave (OOA) solution if a ply ends up missing or is laid up in the wrong order, and the whole manufacturing process must be restarted. When each supply chain partner can focus on its specialized role and core competencies, with an understanding of how that role achieves the end product objective, everyone wins.

For example, an effective formatting partner should be able to deliver different materials custom-tailored to the requirements of the aircraft manufacturer or tiered supplier — with better quality, faster speed and lower TCA than could be achieved in-house. Today, this often includes slitting, spooling, knife cutting, water-jet cutting, machining, chopping, preform ply stacking or kitting of materials, in formats ready for downstream automated, semi-automated or manual fabrication processes.

An outsource manufacturing partner also can help OEMs experiment with different M&P options before scaling up to a high-volume, mass-production solution. With a robust, outsourced formatting infrastructure at their disposal, aircraft manufacturers have access to the manufacturing equivalent of a gym membership in which to “work out” theories, rule out what doesn’t meet expectations and ramp up what works, at a fraction of the cost and trouble it would take to set up their own “gym” or testing facility.

OEMs and tiered suppliers have the opportunity to outsource their material’s information management to formatting partners. Such management includes predictive analytics for vendor-managed inventory programs, automated prepreg out-time tracking and management of material testing and qualification data.

By investing in equipment, technologies and associates dedicated to these capabilities, material formatters free their supply chain partners of these responsibilities, allowing them to focus resources on their core competencies. And when the innovators of aircraft design and assembly can focus on doing just that, the sky’s the limit in terms of what next-generation aerospace advances they will come up with next!

About the Authors

Michael Quarrey is vice president of Aerospace Operations for Web Industries. He has more than 30 years of management experience focused on creating high-engagement, high-performance teams. Quarrey holds an M.S. in System Dynamics from Dartmouth College and a B.S. in Computer Science from Worcester Polytechnic Institute. He can be reached at mquarrey@webindustries.com.

Ben Winters is general manager for Web Industries Inc. — CAD Cut Services and has more than 25 years of experience in working with aerospace customers. Web Industries is a precision formatter of carbon fiber composites and other materials used in aerospace manufacturing. Winters and the Web team engage with OEMs and tiered suppliers early in product development to devise formatting solutions optimized for the customer’s mix of materials, machines and manufacturing processes. He can be reached at bwinters@webindustries.com.

Related Content

How AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreThe evolution, transformation of DEA from lab measurements to industrial optimization

Over the years, dielectric analysis (DEA) has evolved from a lab measurement technique to a technology that improves efficiency and quality in composites production on the shop floor.

Read MoreComposites opportunities in eVTOLs

As eVTOL OEMs seek to advance program certification, production scale-up and lightweighting, AAM’s penetration into the composites market is moving on an upward trajectory.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More