The structural grid: Prefabrication

Digitally designed and cut, preformed and preinfused stringers and bulkheads reduce boat weight, labor and cycle time and improve boatbuilder process control.

Boatbuilders who survived the recession-driven 80 percent drop in new boat sales face a much more competitive market. With less expendable income and less ready to part with it, boat-buying customers are looking for deals but aren’t willing to deal away boat quality or performance. Advancements in digitized process control and machining have reduced boatbuilding costs from design and development to part fabrication. But the benefits of such technology, as the recession approached, were largely limited to boatbuilding enterprises that could afford the upfront investment in the computer-driven technologies. Niche builders of racing yachts (see “Infused CFRP: New One-Design paradigm,” under "Editor's Picks," at top right) and high-end, high-performance powerboats have relied on digital design and machining for decades. But a majority, builders of 20- to 40-ft production powerboats, have often lacked the financial or technical resources to chart a digital course. In response, boatbuilding suppliers have taken on some of the digitally driven manufacturing tasks. One result is prefabricated structures ranging from precision-cut preformed stringers and bulkheads to precured, one-piece “drop-in” stringer/bulkhead assemblies. Such services are helping recession-battered boatbuilders get back on course without having to negotiate steep learning curves or accrue additional debt, yet they can take advantage of the multiple benefits of digitized design and construction.

Structural Grid 101

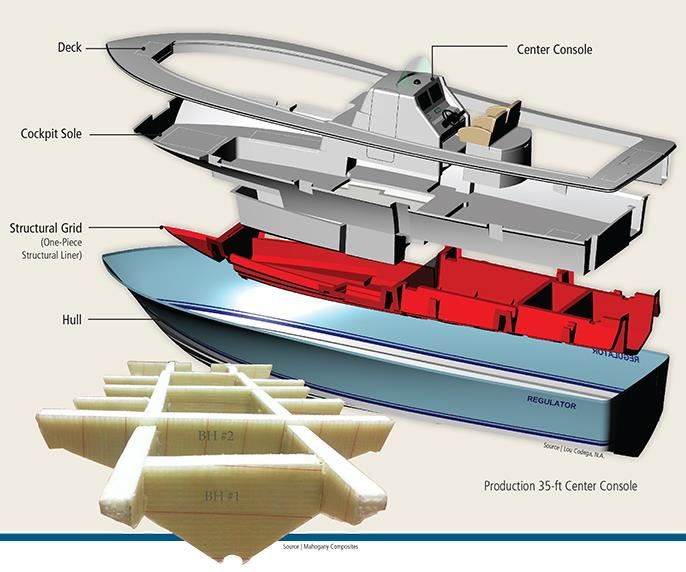

Although much attention is paid to the hull and deck — what composite powerboat builders call the “shoebox” — the complex structures that support them account for a significant percentage of a boatbuilder’s overall design, fabrication and assembly challenges. These internal structures, primarily longitudinal stringers and transverse bulkheads, are far from unimportant, says Russ Elkin, senior technical service engineer, Baltek Inc., a division of 3A Composites (High Point, N.C.). They form a structural grid that supports the bottom plating, distributes load throughout the hull, and maintains the integrity of the shoebox and provides support/landings for the cockpit or cabin sole (floor).

This structural grid might be a traditional “egg crate” made from fiberglass-encapsulated plywood, or the builder might have replaced the plywood with as foam or balsa. Other options include intersecting hollow or foam-filled hat sections or a unitized molded grillage. Although each piece can be built separately and then joined in the hull, this is time and labor intensive, especially when the grid is pieced together following hull lamination and cure. Elkin says the better alternative is to “integrate these pieces into a one-piece structural liner.” This practice, he adds, “can reduce fabrication from a large number of parts down to a five-piece boat” (see Fig. 1).

Ideally, the boatbuilder builds the hull and the grid in parallel and then quickly mates them with adhesives. Although this vastly reduces the build time, designing and building tools that will yield grid components that can be mated exactly with the hull contours requires much expertise and significant effort. Supplier prefabrication, then, provides an intermediate approach as a manufacturer moves forward from traditional plywood stringers and bulkheads. Elkin adds, “If you don’t want to go all the way to an integrated structural liner, then you can use prefabricated pieces. This still requires some engineering work up front, but where this capability was out of reach for many builders in the past, it is readily available today.”

Here CT explores why and profiles three prominent structural grid suppliers, the similarities and differences in their approaches, why those differences matter and — not least — the benefits that accrue to boatbuilders who buy their services.

Kits to complete grids

“We started out by simply supplying kits,” recalls Mike Brennan, vice president of one prefab structures pioneer, Mahogany Company of Mays Landing Inc. (Mays Landing, N.J.). Thirteen years ago the company began helping its customers by precutting polyvinyl chloride (PVC) foam core to shape and kitting it for customers’ stringer production. “Making the stringers,” he says, “is simply the next step.”

Mahogany works with the customer on grid design. “The customer owns the design,” Brennan explains, “and is responsible for ultimate engineering approval and certification, but we provide a lot of guidance, based on our long history with so many different material combinations.”

Mahogany now uses a variety of cores, from all kinds of foam to balsa. “Most of our products use polyester resin, but if the customer wants to use carbon or aramid fiber, we require vinyl ester or epoxy resin,” says Brennan. “Polyester has problems bonding to carbon, and for customers investing in more exotic fibers and hybrid fabrics, it makes sense to obtain the full benefits by using resins that attain better physical properties for the overall composite.” Mahogany uses three resin suppliers: Interplastic Corp. (St. Paul, Minn.), Reichhold LLC2 (Research Triangle Park, N.C.) and Ashland LLC (Dublin, Ohio). Vectorply Corporation (Phenix City, Ala.) supplies most reinforcements, and core is from 3A Composites (Mooresville, N.C.).

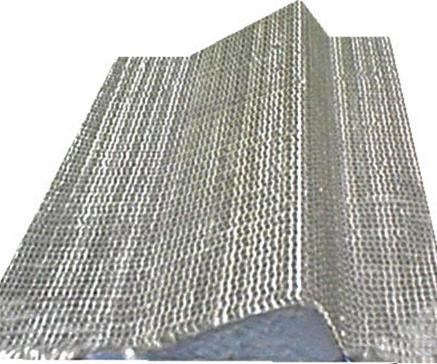

The design-specified fabrics are wet layed onto the core and cured in a heated press to produce 4-ft by 8-ft (1.2m by 2.4m) panels ranging in thickness from 1 inch to 4 inches (25 mm to 102 mm). Thicknesses may vary among components for the same structural system, Brennan explains, depending on localized requirements.

Mahogany uses peel ply on both faceskins “so the panels can be secondarily bonded with good adhesion and without any sanding or further surface preparation required,” says Brennan. Stringers are then CNC cut from the panels. Mahogany uses a Komo Machine Inc. (Lakewood, N.J.) machining center and a CNC router supplied by Anderson America Corp. (Pineville, N.C.). “We also number and package them with an installation drawing that shows how to put the grid together.”

The prefab stringers aren’t for everyone, Brennan points out, noting that the more tech-current “customers who are building their boats using closed molding just buy kitted core and reinforcements from us.” But open molders are taking to it in greater numbers.

“The finished product is a replacement for a plywood stringer, but it is lighter,” says Brennan, explaining that with prefabricated stringers the only lamination required is to cap the top and apply resin to the reinforcement tabs that attach the stringer to the hull. Using a prefab grid can save up to 50 percent in construction time. And Baltek’s Elkin says replacing plywood stringers covered in woven roving with foam-cored composite panels allows builders to keep the same shape at 50 percent the weight of plywood.

“However,” he cautions, “the structural properties are different. You will need to do a bit of redesigning to make sure you are handling all of your loads and specify your materials accurately.” Previously, most of the stress was distributed by the plywood, but with foam-cored panels, the stress goes into the fiberglass. Elkin advises, “You want to spread the load over a greater area in order to make sure the stress is not too high, so we advise a minimum 1-inch [25.4-mm] panel thickness.”

Infused prefabrications

Gurit (USA) Inc.’s (Bristol, R.I.) prefabricated Hi-Panel structures also began with a kitting program. “It has developed out of our B3 SmartPac business,” says Mathieu Cariou, Gurit’s B3 SmartPac product manager, “and consists of making infused composite panels to customer specifications.”

B³ SmartPac kits are supplied as core only, reinforcements only or both, but the individual components are neither joined nor impregnated. “Hi-Panel kits are made from pre-infused composite panels,” he explains, “which the customer simply tabs into the boat, enabling very quick construction.” The company also can make panels via hand layup, but Cariou says more than 80 percent of Hi-Panel structures are infused and exploit the full range of Gurit core materials, including PVC, polyethylene terephthalate (PET) and styrene acrylonitrile (SAN) foam, as well as balsa wood. “We mainly use epoxy resin,” notes Cariou, “because we produce it ourselves, but we also use vinyl ester.”

Hi-Panel is manufactured in sizes up to 2m by 9m (6.6 ft by 29.5 ft), limited only by CNC machine size. Cariou says the departure from 4-ft by 8-ft (1.2m by 2.4m) panels — the same size as a standard plywood panel — is strategic: “We are using 2m by 9m panels because it means fewer panels, less joining and less fairing, all of which is quicker for the builder.” Cariou adds, “We potentially have ways to produce larger sizes and can look into this based on customer demand.”

As with B³ SmartPac, production begins with a customer-supplied 2-D or 3-D computer-aided design (CAD) file. At its Bristol, R.I., and Auckland, New Zealand, locations, Hi-Panel techs “work with the customer’s engineers, in-house or contracted, to make the Hi-Panel structure as efficient as possible,” says Cariou, noting that each location has two separate departments. “One is structural engineering — for example, how much of each material is required and where — and for the Hi-Panel system we also use our process design group, optimizing the structural shapes and build process for each project.” Gurit cuts glass fabrics on an Eastman Machine Co. (Buffalo, N.Y.) flatbed cutting system. Stringer and bulkheads shapes are routed out of preinfused panels, using a large flatbed CNC system from machine builder MultiCam Inc. (Dallas, Texas).

Preformed vs. prefabricated

“Our process is different,” says Scott Lewit, president of Compsys Inc. (Melbourne, Fla.), a sister company of Melbourne-based boatbuilder Structural Composites Inc. “While other prefab structures suppliers cut flat stock on CNC routers,” he explains, “we use a mold to make custom preforms.”

Compsys has manufactured its PRISMA preforms since 1994. Its process is digital from start to finish and, therefore, reportedly maintains a very high level of control and quality. “We CNC cut all of our fiberglass fabrics,” says Lewit, adding that his flatbed cutting system, from Eastman Machine, has an airbrush printer which marks specific part information onto each piece, “much like the data found on a part drawing.”

Using customers’ CAD files, “we often design the complete stringer system, which means we design the mold tools used to produce the preforms,” Lewit notes. “We take this digital file and then use it to CNC-generate tooling and material-cutting patterns.” The patterns are loaded into Compsys’ manufacturing database system, which is part of the value offered, according to Lewit. “The whole bill of materials for the stringer system is in our database, and we keep track of changes and updates.” Nesting software minimizes waste and downtime.

The mold is lined with fabric, internal structures (e.g., bracing points for hardware, motor mounts, electrical and fuel line conduits, etc.) are positioned, and then a low-density, two-part polyurethane flotation foam is injected (see Fig. 2).

Typically the foam is nonstructural. “However, because we have encased it in fiber, and designed the reinforcements appropriately, the overall composite has exactly the structural properties required for each area of the boat,” says Lewit. “The foam injection system is also connected to the computerized production system,” he adds, noting that it is “wired to the same data file, and so it knows how much foam to inject into each part.” The very low-density (e.g., 2 lb/ft3) foam expands into the cavity, adheres mechanically to the reinforcements, and cures in 10 to 60 minutes, depending on part dimensions. The finished preforms are production ready, and the foam ensures they will not fill with resin during closed molding. “Unlike hollow stringers, the preform system can be co-infused and primary bonded with the hull laminate, which improves the structure, eliminates the expense of adhesives and saves weight.”

“When we design the stringer system, we know if it is going to be fabricated using open or closed molding,” Lewit says. This is important because the fabrics used are quite different. “For closed molded parts, lofty fabrics are often beneficial, because they fill nooks and crannies during the infusion process. However, these same fabrics would not be good at all for open molding.”

Although many fabric types can be used for the preforms, Lewit says Compsys customers frequently take advantage of a special triaxial fabric that comprises a double-bias glass fabric and a unidirectional carbon fiber tape. “Once the preform is molded, you end up with a built-in spar cap for increased stiffness, but without that time and labor in the shop,” he explains.

Baltek’s Elkin adds that the additional expense for a triaxial fabric is easy to justify. “Traditionally, we see a lot of mat and woven fabrics used for stringers,” but their use, he maintains, is a matter of custom rather than calculation. They were used in traditional laminates designed for hulls and simply moved over and applied to the structural grid. “These are not very efficient materials and result in extra weight and material usage,” Elkin contends. He points out that “the engineering for stringers is completely different than that for a hull.” It is much more efficient to use triaxial fabrics for a stringer, he notes, “putting the fiber exactly and only where you need it.” Less fabric is used overall, and its use requires less labor.

Custom PRISMA preforms, says Lewit, significantly expedite production for closed molders, such as Cigarette’s (Opa-locka, Fla.) 42-ft powerboat. “Before, it took them over one week to produce and glass-in the entire stringer and bulkhead system,” Lewit reports, “but now they are down to one day.” (See Fig. 3.)

For boatbuilders who can’t afford custom preforms, Compsys also produces 30 to 40 “generic” shapes made by feeding rolls of continuous fabrics (selected based on the design of the stringer shape) into a simple die, which is then filled with two-part flotation foam. “We can make any shape we want as long as it has a constant cross-section. These products are very cost-effective because the process is continuous and fast — up to 1 mile of continuous preforms produced in six hours.” Although customers must cut and otherwise modify the generic preforms, Lewit says they can still net a labor savings of up to 50 percent.

Boat-wide benefits

Notably, the benefits of digitized preforming and prefabrication go beyond saving weight in the grid and reducing labor. The grid design can save weight elsewhere as well. “We will often suggest a change of materials aimed at using larger, lighter weight stringers,” says Compsys’ Lewit. When a stringer system is reengineered to better distribute stress, he explains, the builder can go with a thinner and, therefore, lighter hull structure. “You can pull glass out of the hull, which is where big cost and time savings can be achieved.”

Mahogany’s Brennan adds that benefits also include business risk and cost containment. “Most shops immediately understand that we are offering a very consistent product at a flat price,” he says. “There are no variables due to mistakes, wrong fabrics, different speeds in workers, etc.” And, he emphasizes, the supplier’s controlled process also buys the customer security. “We … obtain an optimized yield through using digital files and nesting programs with the CNC machining, and we check one out of every 20 panels for thickness, and one out of every 100 is sent out for physical property testing.” As a result, Brennan points out, Mahogany has not had a single failure in the 13 years it has produced prefabricated cored panels for structures and in its three-year history of CNC-cut stringers and bulkheads.

“We often help close the gap between engineering and production,” says Brennan. “If something is wrong, we work with them to get the part right, which may mean reworking the design and/or materials.” This type of support also is extended to customers who make changes in a given model. “If the fishbox is moved up three inches, now the length of the longitudinals changes, as does the placement of the transverse bulkheads.”

When a 30-ft fishing boat manufacturer changed one section from 21-inch (533-mm) stringer spacing to 23-inch (584-mm) spacing, Mahogany accordingly redesigned the whole grid and submitted it back to the customer’s engineers for final approval. Brennan adds, “This process may even demand assistance from material suppliers — we work a lot with Russ Elkin at Baltek and Trevor Gundberg from Vectorply — in order to make sure the required physical properties and structural performance are met.”

Gurit’s Cariou also underscores the benefit of design consultation and construction guidance. On the recently completed 56-ft/17m performance cruiser Alcedo, for example, built by MB Yachts Ltd. (Dorset, U.K.), Gurit worked “with the naval architect, Stimson Yachts [Auckland, New Zealand] … to determine where the panels would go and how they would be joined,” says Cariou. “The shapes were labeled not only with their location, but where additional patching and joining was required” (see Fig. 4). Additionally, the entire assembly and installation process was outlined and explained in the manual Gurit developed and sends with each outgoing shipment of Hi-Panel structures. “Thus, the boat construction process itself went much quicker compared to traditional methods,” notes Cariou. Stimson estimated a 50 percent reduction in the time required for construction. For the 78-ft/23.8m power catamaran IETA, the benefits were similar but provided a uniquely enabling solution for builder Marc Deborde in New Caledonia (an island in the southwest Pacific roughly 750 miles/1,207 km east of Australia). Deborde used a relatively inexperienced crew and needed a bill of materials and a build process that would allow him to manage his budget and ensure his customer would receive a quality product.

“The Hi-Panel system certainly saved us time throughout the build process,” Deborde recalls. “The parts were clearly labeled … and were extremely easy for my team to assemble, with minimal tooling and no lifting equipment required. The main structure was built in a matter of weeks.” (See Fig. 5.) Deborde also cites low setup costs, ease of storing the panels prior to use and having everything thought out and organized at the beginning of the project.

Gurit CNC cut the Corecell M-Foam/glass fiber sandwich panels for IETA in New Zealand and left them “tabbed” in the stock panels for easier stacking and shipping in containers to New Caledonia.

Lighter, faster, better … and better

As suppliers continue to provide prefabrication services, a final benefit to the boatbuilder is the suppliers’ accumulated experience. Each year the structural grid engineers at supplier prefab facilities experience an increasingly greater range of design challenges on many different boat designs and sizes. “We have gotten smarter and smarter with the PRISMA beams, enabling us to save builders more cost and weight than ever before,” comments Lewit. “This pays off not only in more fabric and resin out of the hull, but in smaller engines, and smaller and less expensive trailers, which all adds up to a less expensive boat at the same length.”

The prefabrication trend will grow and, Lewit believes, is really just a beginning. The cost of boating will define the industry in the coming decade, and the overriding question will be how to increase the fuel efficiency of boats without sacrificing performance. Those who have mastered the arts of digitally driven design and construction will provide the answer.

Molding Products LLC

Related Content

Pro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreNlcomp launches recyclable composite sailing boat Ecoracer30

Italian startup featured its 30-foot sustainable production boat at the Ocean Race Grand Finale in Genoa, Italy, citing the challenges, highlights and future related to its development.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreAlliance for European Flax-Linen and Hemp reports increasing flax fiber adoption in marine

The natural fiber is increasing traction across several marine applications, including in projects by Greenboats, Northern Light Composites, the Beneteau Group and others.

Read MoreRead Next

Infused CFRP: New One-Design paradigm

The Farr 400 opens a new frontier in Grand Prix sail racing, with greater precision at lower cost.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More