Thermwood’s vertical layer printing turns AM on its side

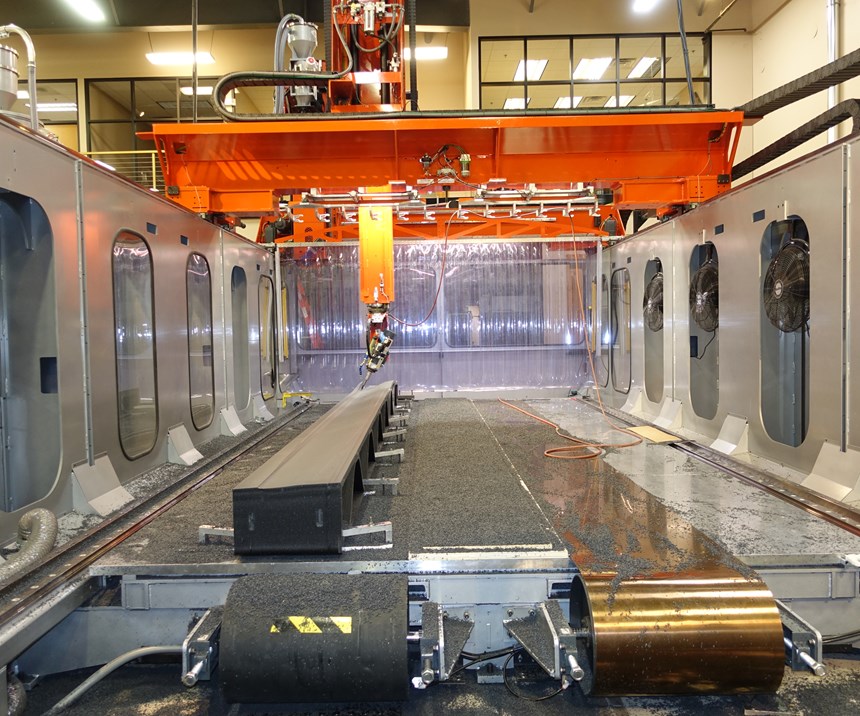

Vertical Layer Printing (VLP) 3D prints layers perpendicular to the floor, extending Z height to the length of the print bed — as long as 40 feet.

Vertical Layer Printing (VLP) at first sounds counterintuitive. This new 3D printing strategy developed by Thermwood makes use of the company’s Large Scale Additive Manufacturing (LSAM) system, but instead of putting down layers of material that are parallel to the floor, VLP literally turns the process on its side. A print head oriented at a right angle to the extruder deposits material in layers perpendicular to the floor, onto a vertical print bed.

The main benefit to printing this way is size. The LSAM’s print envelope is 10 feet wide and can be 20 to 100 feet long, but is only 5 feet high. That limits the size of parts that can be manufactured in one piece with a horizontal print bed, says Jason Susnjara, vice president of marketing.

A recent project provides an example. Thermwood 3D-printed a mold for a boat hull at its Dale, Indiana, facility using the LSAM with the standard horizontal layer orientation. “We didn’t have vertical at that time, so everything was done horizontally, in six different pieces,” Susnjara says. After printing, each part was machined individually, then assembled with its fellows and finished. “It still only took 10 days to print, machine and add all those pieces together. However, with VLP we can print that boat hull form in one piece continuously, and probably save half the time.” This strategy would have avoided the assembly step and thanks to the machining gantry option available on the LSAM, it even could have been possible to finish machine the form without moving it. (Learn more about Thermwood’s recent boat hull project in “TAHOE Boats' T16 uses 3D printed tooling from Thermwood.”)

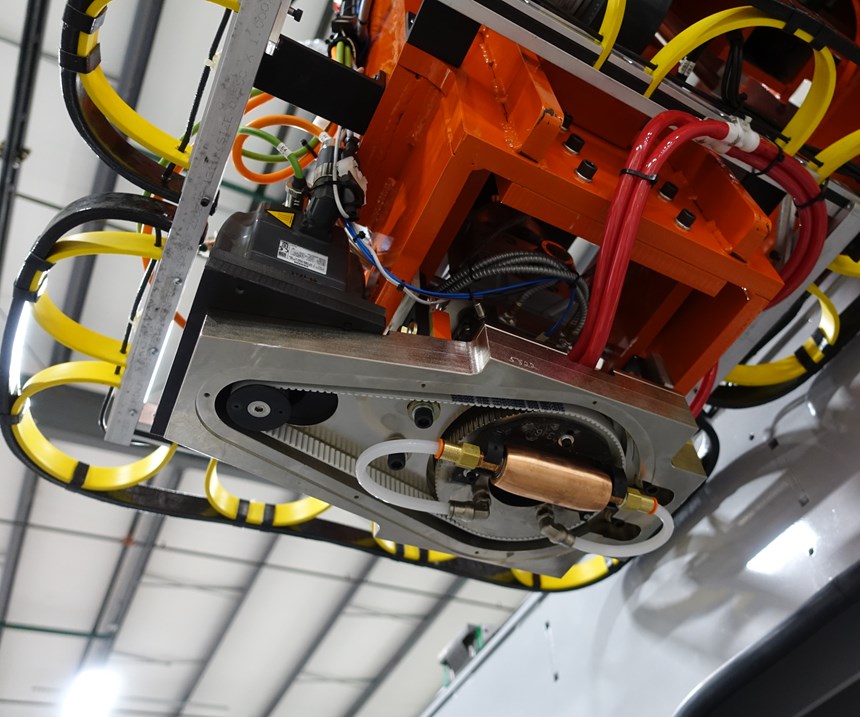

VLP is now an option for the LSAM. The same system can print in both orientations with just a few changes in hardware and software. Customers who want Vertical Layer Printing capability receive the VLP print head and a vertically oriented build plate. As the head prints the layers moving only in the Y and Z axes, the motor-driven build platform slides the part backward layer by layer in X on two Teflon-coated stainless steel belts.

What makes the process counterintuitive, of course, is gravity. Layers printed perpendicular to the floor have the potential to sag and bring the print out of tolerance. Thermwood has several tools to counter this danger:

- A compression wheel. As the print head lays down the bead, it is followed by a compression wheel that presses the new material into the layer beneath, ensuring good layer adhesion whether in a horizontal or vertical orientation.

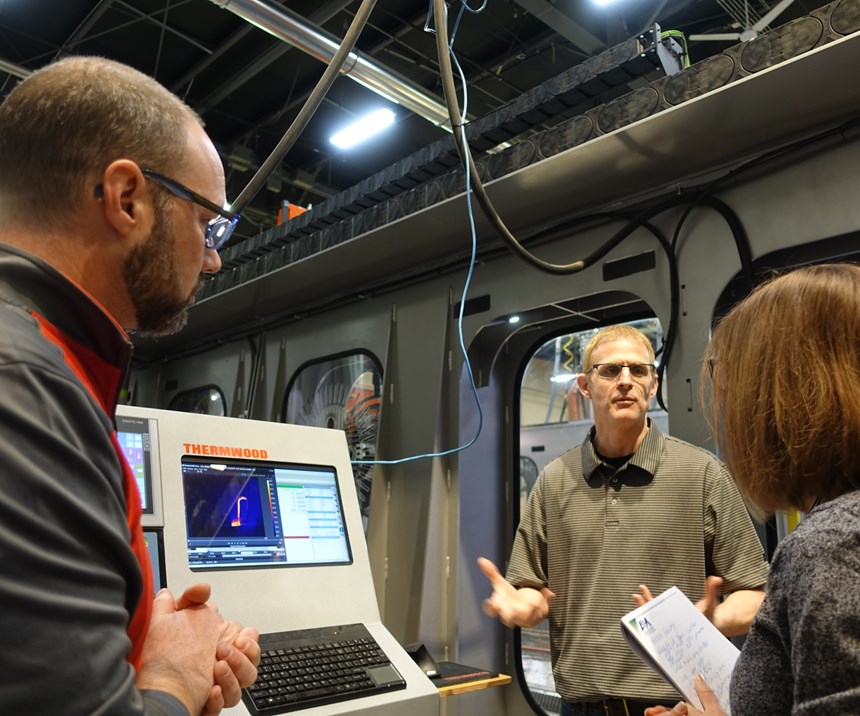

- Dynamic print adjustment based on thermal imaging. The LSAM is equipped with a thermal camera that monitors the heat of the part as it is printed, enabling what Thermwood calls “Continuous Cooling” printing. The system’s software controls the print so that new layers are added when the previous layers are at the optimal temperature — neither too hot, which could cause distortion, nor too cool, which could cause delamination. This careful attention to print temperature coupled with the compression wheel results in layer adhesion such that parts can hold a vacuum right off the printer without coating, the company says.

- A hybrid manufacturing approach. When sagging can’t be avoided completely because of the geometry of the part, the LSAM offers a built-in fix. Features can simply be designed and printed larger than necessary, and finish machined with the LSAM’s five-axis milling head to net shape. Or, if the finishing will be performed on a different CNC machine tool, a router head can machine reference points into the part before the move to ease the setup.

One early success for Vertical Layer Printing was a large R&D tool produced for Boeing which was in progress at the time of my visit. The final tool measuring 12 feet long was printed in a single piece from ABS with a 20 percent carbon fiber fill. While the tool’s size did not necessarily preclude horizontal-oriented printing, its mostly hollow construction might have been difficult to print in this direction. VLP saved material and increased confidence by making it possible to print the tool without additional bracing or supports to hold up its top curve.

See VLP in action in this video.

This story originally appeared on AdditiveManufacturing.Media

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

TAHOE Boats' T16 uses 3D printed tooling from Thermwood

Thermwood’s Large Scale Additive Manufacturing (LSAM) system was utilized to custom-print the tool used to manufacture the boat’s hull.

Read MoreThermwood 3D prints large boat hull pattern

Thermwood uses its LSAM additive manufacturing technology to fabricate a 3,000-lb/1,363-kg plug for a boat hull. The project proves the viability of additive manufacturing to help reduce marine composites fabrication costs.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)