Third wind blade break for GE

NA Windpower reports a third 48.7m blade has broken off a GE 1.6-100 turbine.

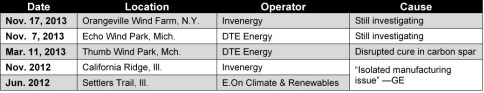

North American Windpower reported this week that a third 48.7m/160-ft blade has broken off a GE 1.6-100 turbine. All three breaks happened either during or shortly after turbine commissioning. No one was injured in any of the breaks.

The most recent occurred at Invenergy’s (Chicago, Ill.) Orangeville Wind Farm in New York. A blade on turbine #34 snapped near the hub, with most of it falling to the ground, leaving a jagged stub.

Though the first and second breaks in 2013 — both in Michigan wind farms operated by DTE Energy (Detroit, Mich.) — sound similar, they look very different from the one in Orangeville. The Nov. 7 break of a blade on Echo Wind Park’s #60 turbine and the Mar. 11 break on one of 40 turbines in Thumb Wind Park’s Sigel Township installation (officially dedicated October 2012) both show separation of the blade along its length. The Orangeville blade showed more of a clean snap.

In fact, the earlier 2013 breaks look more similar to two GE 1.6-100 turbine blade breaks in 2012, both in Illinois. In an image from the California Ridge Wind Farm, the carbon spar used in GE’s 48.7m blades can be clearly seen. According to GE Renewable Energy spokesperson Lindsay Theile, an “isolated manufacturing issue was the cause of the two blade fault occurrences.” Though the precise nature of the issue was not disclosed, the Mar. 11 break at DTE’s Thumb Wind Park was attributed to a failure in the carbon fiber spar “at the 19-meter mark” caused by an accidental 2-hour oven shutdown during cure.

RechargeNews.com stated the Echo Wind Park blade was made in Brazil. Tecsis (Sorocaba, Sao Paulo state, Brazil) had a $1 billion contract to supply blades to GE for U.S. wind power projects from 2006-2010. In a 2012 Wind Turbine Overview for the World Bank, GE presented its 1.6-100 turbine blade testing overview with a photo beside “Certification Requirements” titled “GE-Tecsis Collaboration”. Thus, GE and Tecsis have had a close relationship, and it is possible, if not likely, that the five GE 1.6-100 blades that have failed in 2012-2013 were produced by Tecsis in Brazil.

Tecsis was founded in 1995 by aeronautical engineer Bento Koike. In 2012 it was listed as the second largest blade manufacturer in the world, behind LM Wind Power. A 2009 article by PIB magazine claimed Tecsis had supplied half the blades in operation in North America and held more than 40 international patents on blade technology. A Sep. 2012 article from Valor explained that the company filed bankruptcy in 2010 but has emerged stronger, with positive earnings in 2012 based on revenue of US$700, a doubling over 2011. It also increased production from 10 to 12 blades per day to 30 and said it supplied “besides GE,” Alstom, Gamesa, Impsa and Siemens. 2012 production was slated at 5,500 blades. The company described its largest blade as 50m (i.e. the 48.7m for GE) and weighing roughly 9 tons (19,842 lb). Interestingly, Tecsis director of operations Ventura Pobre, previously from a maintenance services subsidiary in the U.S., is credited with developing a new solution for carbon fiber application in the “record time” of one year, which reduced blade weight from 9 to 6 tons. The article explains, “The base material is not simple at all and needs to be transported and stored under special conditions.” This seems to point to a recent switch to prepreg for the spar caps. In a 2008 presentation, GE showed carbon fiber spar caps being infused, layed into the fiberglass and balsa core blade shell layups and then infused. Meanwhile, Composites Technology magazine (Oct 2013) reported the blades are E-glass/epoxy sandwich construction with a hybrid core using balsa wood plus PVC and SAN foams.

Time will tell what these blade failures have in common, and why they’re occurring, but in the meantime it is important to note that they are quite different from the previous blade failures experienced by Gamesa in 2007 and Siemens earlier this year. For Gamesa, a defect in a foot-long applicator produced an irregular line of adhesive, causing splintering and breakage in 13 of nearly 400 blades produced at its Ebensburg, Pa. plant that year. Seven blade failures were first observed at the Allegheny Ridge Wind Farm in Pennsylvania. The problem was corrected and the blades were replaced.

Siemens responded quickly to two B53 (53m/174 ft long) blade failures in its SWT-2.3-108 turbines at the Eclipse wind farm in Iowa and the Ocotillo Wind project in Calilfornia. It immediately curtailed production of that turbine, performed a root-cause analysis and determined the cause was adhesive bonding failure between pre-cast root segments and the main blade fiberglass laminate due to insufficient surface preparation. All B53 blades have been inspected and most are back in operation. Siemens will replace a number of blades due to delamination and will apply a minor modification in the field to all B53 blades that are not replaced, incurring $131 million in charges toward 3rd quarter 2013 results.

The GE 1.6-100 turbine was touted as the most popular U.S. wind turbine installation in 2012 by Navigant Research and was named 2012 Turbine of the Year by Windpower Monthly for kick-starting the large-rotor trend, which, when combined with modest generator power, has reduced the cost of energy. It has also helped GE to surpass Vestas as the number one turbine supplier in the world.

It’s important to keep these blade failures in perspective. According to published GE announcements, it expects to install 1,500 1.6-100 turbines by the end of 2013, for a total of 4,500 blades. Including the two failures in 2012, a total of five failures translates into 0.1 percent of production. As comparison, the 10 largest automobile recalls in 2013 (as of July) reported by the U.S. National Highway Transportation Safety Administration (NHTSA) totaled 8,471,045 vehicles, which represents 27 percent of the 31.4 million vehicles produced in North America during 2012-2013. Realize, these recalls were all for serious issues with brakes, airbags and potential for fires. Granted, the comparison is not direct because the car models affected can date back before 2012. However, just the portion of recalls that affect mainly 2012-2013 model years totals more than 2 million vehicles, or 6.5 percent of North American production.

Yes, there have been failures, but so far, they have affected a very small percentage of the total blades produced and installed. If GE follows Gamesa and Siemens in conducting a swift investigation and correction, it should be able to maintain the industry confidence it has duly earned.

Related Content

Achieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRead Next

Wind blades: Progress and challenges

Despite double-digit wind energy industry growth, turbine blade manufacturers and materials suppliers acknowledge a pressing need to reduce costs and innovate.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More