United Launch Alliance rocket ushers sigh of relief

With nerves frayed over the uncertainty regarding the supply of Russian-made rockets, ULA joins SpaceX with the development of a new heavy-lift rocket to help preserve American space security.

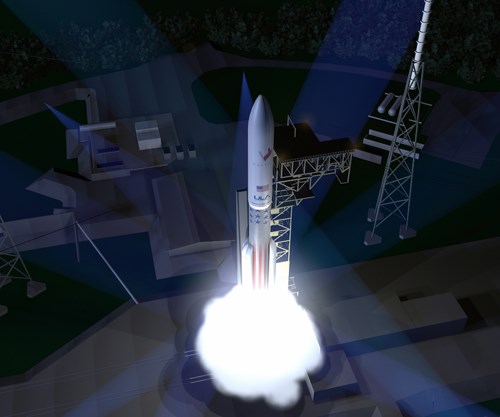

ULA's Vulcan rocket, announced this week at the 31st Space Symposium, gives the US space program another option for putting people and equipment into space.

If you haven't been paying close attention to the space launch industry of late, you probably didn't know that it had been made quite complicated by Vladimir Putin. Indeed, the Russian leader's foreign policy antics in Ukraine, combined with some of his anti-United State rhetoric, has strained Russian-US relations, raising the spectre of the Cold War political struggles — even if only symbolically for now.

What's this have to do with space launches? For many years the United States has relied on Russia to supply its RD-180 rocket to power satellites and other craft into Earth orbit and beyond on the Atlas V launch vehicle. The R-180 is supplied by NPO Energomash (Khimki, Russia); the Atlas V is manufactured by United Launch Alliance (ULA, Denver, CO, US). However, as relations with Russia soured, this sole-source supply situaiton became, to put it mildly, unsustainable. It's been feared that if Russia were of the mind to do so, it could cease supply of the RD-180, leaving the US with no immediate alternative on hand. This has spurred the US government to call for US-made alternatives to the RD-180.

So, it was a big deal this week when ULA announced at the 31st Space Symposium in Colorado Springs, CO, that it is developing a new rocket, called Vulcan, designed to make "launch services more affordable and accessible," according to a ULA statement. ULA, the statement also notes, is responsible for more than 70% of the nation's space launches, so a new rocket source is critically important. In addition, ULA introduced with Vulcan the Sensible, Modular, Autonomous Return Technology (SMART) initiative, which will allow ULA to re-use the most expensive portion of the first stage — the booster main engines — via mid-air capture.

Neither is ULA alone in its rocket development. SpaceX (Hawthorne, CA, US) is working on a heavy-lift rocket, the Falcon Heavy, which will launch for the first time later this year. It has a payload of 117,000 lb, which makes it among the largest rockets ever made.

The upshot is that the US, finally, seems to have some rocket independence, which gives the American space program some much-needed space-access security.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.