Vinyl ester composite parts in boat stern drive resist corrosion and damage

Volvo Penta's Ocean Series brings vinyl ester composites to the powertrain end of the boat.

The advantages of polymer composites in marine environments long have been recognized. Most notably, composites have replaced metal and wood in floating structures, such as the hulls of boats and personal watercraft. But the high corrosion resistance, low weight and reduced need for maintenance of the materials also have extended the application base to piers, pilings and other fixed structures and, more recently, to offshore oil platforms. Against this paradigm, boat powertrains have been stubbornly resistant to composites-for-metal substitution. Volvo Penta (Chesapeake, Va., U.S.A.), the marine division of Sweden's Volvo Group, changed that with the 2002 introduction of the Ocean Series OSi stern drive, employing structural composites in critical drive components that are exposed to harsh saltwater environments. Mated with 4.3L to 5.7L, 225 hp to 320 hp gasoline engines, the Ocean Series drives are offered today by a number of boat manufacturers, including Rinker Boats, Hunt Marine and Genmar (the Sea Swirl and Wellcraft lines).

"Our initial target for the Ocean Series was the saltwater fishing market," explains Paul Dierksen, senior VP of marketing for Volvo Penta. Dierksen notes that this market had become increasingly dependent on large outboard engines, which can be easily raised out of the water when not in use, away from the corrosive effects of seawater. However, outboard engines consume valuable space at the rear of the boat, an important consideration for fishermen. By contrast, a stern drive's engine is secured inboard, below the deck and just ahead of the hull's rear panel or transom. Only the drive unit is outboard, attached to the transom's exterior. The drive shaft and associated wiring and controls pass through the sealed interface. As boatbuilders have transitioned from two-stroke to larger, heavier four-stroke outboard engines to meet more stringent emissions requirements, the way has opened for an improved stern drive solution like the Ocean Series.

Vinyl ester composites have driven the improvement, replacing aluminum in five molded components of the Ocean Series outboard drive unit: left and right cowlings, access cover, a heavily loaded gimbal ring, and the gimbal housing (also called the transom shield). "Composites provided the needed corrosion resistance and gave us the flexibility to design a product with improved performance characteristics and reliability," says Dierksen.

Three Part Harmony - Design, Material, Molding

At the start of the project, Volvo Penta engineers knew that polymer composites could provide the desired corrosion resistance, based on success in hull structures, but they had no experience in composite design and molding because their history had always dictated aluminum. "Our first task was identifying composite materials and processes we could use for these kinds of parts," says Volvo Penta design engineer Matt Wilkins. The previous components had been cast aluminum, because the casting process could accurately reproduce the complex molded surfaces. For the composite replacements, compression molding appeared to offer this capability. "We started looking for materials with property profiles similar to aluminum," Wilkins continues, "and the products supplied by Quantum Composites (Bay City, Mich., U.S.A.) offered the best performance profile."

After screening a number of materials, the team selected Quantum's QC-8700 Engineered Structural Composite molding compound, a vinyl ester SMC reinforced with 63 percent 25 mm/1-inch glass fibers. Designed for metal replacement applications, its key properties include flexural strength of 92,000 psi (633 MPa), flexural modulus of 3 million psi (20,600 MPa) and impact strength of 33 ft-lb/inch (1,760 J/m), notes Matt Douglas, Quantum Composites product manager. QC-8700 retains more than 80 percent of room temperature stiffness at 66°C/150°F, important given the heat generated by the gears inside the stern drive.

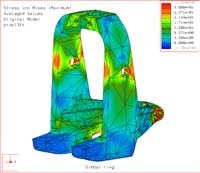

Design and material development were integrally linked to the evolution of the molding process for the prototypes. The CAD drawings were created in ProEngineer (PTC, Needham, Mass., U.S.A.), and several iterations of finite element analysis were conducted, using software supplied by ANSYS Inc. (Canonsburg, Pa., U.S.A.). Prototyping was done in the production molds, which were constructed of P20 steel by R&R Tool and Mold, a division of Valiant Corp. (Windsor, Ontario, Canada). Between each iteration, molding trials helped refine the succeeding analyses and guided engineers through a series of changes to the molds. "We learned a lot about the material performance during molding," Wilkins explains. For example, the mold for the 510-mm/20-inch diameter gimbal ring initially formed the attachment holes for the drive leg and the trim cylinder. However, this design resulted in less-than-optimal fiber orientation and weaknesses due to knit lines - undesirable results because the gimbal ring bears much of the thrust load when the boat is steered left or right. The revised process, selected for production, molds the ring as a solid piece with post-molding machining of the attachment holes, resulting in a much stronger part. Onsite for much of the prototype molding, Quantum Composites' quality assurance/technical services manager Mike Kiesel concurs with Wilkins. "The molds and molding process for high fiber-content materials must be designed with the charge patterns in mind," he emphasizes. In simple parts, the SMC charge pattern may consist of several layers, stacked and placed in a single area of the mold, relying on the compressive force of the press to distribute the material throughout the part. For more complex parts, like the cowling halves, the charge patterns require multiple stacks of SMC, strategically placed throughout the mold. Optimal stack composition and placement was extensively explored, with Quantum Composites providing mechanical testing and burnouts to better understand the effects of flow-induced fiber orientation. (In a "burnout," samples cut from molded parts are put into a furnace. The resin burns off, leaving the fiber in the as-molded orientation, permitting analysis of fiber flow and breakage.) These results were plugged back into the finite element analysis to ensure that knit lines and any high fiber orientation occurred in areas of lower stress.

Molded part thickness for the cowling, access cover and gimbal housing average 5 mm/0.2 inch, which is similar to the die-cast aluminum design. Weight savings are achieved due to the lower density of the QC-8700. The highly loaded gimbal ring, typically produced in aluminum, varies from 25 to 38 mm/1 to 1.5 inches in thickness, which provided yet another molding challenge. The initial material formulations resulted in thick-section exotherm, so the QC-8700 catalyst package was modified to achieve the proper cure speed, says Kiesel.

Stringent Testing Program Validates Composite Performance

Before the Ocean Series stern drive was offered for sale, extensive qualification testing was completed. The first stage included successful fatigue testing to failure at 2.5 times typical lateral and thrust loads. The "typical loads" were derived by outfitting real engines on boats with strain gauges and putting the boats through various maneuvers, explains Emil Hasl, Volvo Penta design engineer. In the second stage, endurance testing, boats representative of multiple types (cruiser, pontoon, fishing, etc.) were outfitted with Ocean Series drives and put through cycle testing. Each cycle included a mixture of wide-open throttle, slalom turns and other operations.

One of the more interesting empirical performance requirements - likely the first of its kind required of a composite driveline component of any sort - was the log impact test. Hasl explains this required a 40 foot (12.2 meter) long, 18 inch (46 cm) diameter log that has been sufficiently soaked so that only 1 inch (25 mm) of the log was exposed above the waterline. A flat-bottom boat, equipped with the Ocean Series engine and (submerged) composite stern drive, was driven across the log at speeds as high as 50 mph (43 knots). The upper limit was equivalent to a 10-ton impact force on the extended drive leg. The test ensured that even under extreme operating conditions the outdrive should suffer little to no damage, with minimal risk of negative environmental impact (e.g., leaking gearcase oil).

The log impact tested more than the impact resistance of the composite material - it also challenged the integrity of the drive leg assembly. The leg's molded cowling halves enclose the interior drive components and an aluminum "endoskeleton," which provides the structural backbone for the drive leg. A two-part epoxy adhesive, supplied by Henkel Loctite (Rocky Hill, Conn., U.S.A.), is used to join the halves. The Volvo Penta team designed a locking joint, which, in conjunction with the adhesive and the vinyl ester SMC, passed the log impact test by a comfortable margin. The adhesively sealed drive leg also reduces the risk of corrosive seawater migrating into the mechanical components, lowering warranty costs. Part count was reduced by one-third, mostly through the elimination of numerous fasteners required by traditional aluminum designs.

Following successful qualification testing, the production molding contract was awarded to Core Molding Technologies (Gaffney, S.C., U.S.A.).

Seaworthy and Selling

The Ocean Series drive was introduced in early 2002 and has been installed on boats ranging from 5.2m/17 ft in a single engine/drive configuration to 9.8m/32 ft, using parallel engines and drives. While a hit with saltwater fishermen, the composite stern drive also has proven popular with ocean-going recreational boaters. The drive unit is designed with a hydrodynamic profile that creates 10 percent less drag in the water, and relies on a single, under-mounted trim cylinder, compared with the two upper mounted cylinders typical of aluminum drives. These design innovations result in less water spray off the drive and up to 15 percent lower fuel consumption than comparable outboards. The use of a two-piece SMC cowling enabled engineers to design a more efficient contour for the molded-in exhaust path to replace the straight pulls used in the previous aluminum die casting, resulting in lower backpressure and reduced engine load. Weight savings of 13.6 kg/30 lb - about 20 percent less than an aluminum stern drive - increased the power-to-weight ratios, resulting in better acceleration and fuel economy. Owner maintenance costs are reduced with a single upper access panel, "lubricated for life" gimbal bearings, and an engine-mounted drive unit oil reservoir. These and other customer friendly features were cited by the National Marine Manufacturers Assn. when it honored the Ocean Series with its "Innovation Award" at the 2002 Miami International Boat Show in Miami, Fla., U.S.A.

Related Content

Belzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreFilm adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreXlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

Read MoreBiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More