CW Blog

Looking forward to the rescheduled CAMX 2017

Leading the charge vs. follow those who lead the charge.

Read MoreVolvo performance brand features carbon fiber bodies

Volvo launches its Polestar performance brand, the first vehicle of which, the hybrid Polestar 1, will feature a carbon fiber body structure. The Polestar brand is launch with three vehicles, all either hybrid or all-electric.

Read MoreApple Store in Chicago features massive carbon fiber roof

The 111-by-98-ft carbon fiber composite roof is one of the largest single architectural structures in the world.

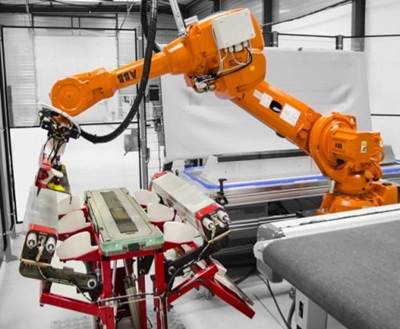

Read MoreAutomated preforming: Intelligent automation in pick-and-place systems

Layups go industrial with hand-like grippers that can fold fabric or prepreg into corners and robot-mounted cameras that inspect from fabric to cut plies to fiber gaps in final preforms.

Read MoreArmor Update: Reinforced elastomeric composite blast barrier

A new, flexible, lightweight, portable debris shield holds promise for protecting building occupants in military zones.

Read MorePlant Tour: FiberCore Europe, Rotterdam, The Netherlands

From debond-proof bridges to cost-saving infrastructure rehab, InfraCore technology is establishing composites as the fourth major construction material.

Read MoreFirst all-electric production yacht features carbon fiber construction

Leader in luxury yacht innovation commits to fossil fuel-less future

WatchComposites and Industry 4.0: Where are we?

As the tide of the Fourth Industrial Revolution rolls in, how will composite manufacturers ride the wave?

Read MoreComposites and metal vie for fuselage and driveshafts in "Racer" next-gen, high-speed rotorcraft

New compound helicopter demonstrator set to fly in 2020 with hybrid fuselage and flexible metal driveshafts for twin pusher turboprops but will trial carbon composite shafts by 2021.

WatchComing soon to the urban waterways: SeaBubbles

All-composite hydrofoiling watercraft will, if SeaBubbles has its way, soon be taxiing people across urban waterways in more than 50 cities across the world.

Read MoreComposites in high-speed marine

Italy-based FB Design’s high-speed boat sets a record on the Montecarlo-Roccella Jonica-Venice sea track.

Read MoreOptimizing composites for the Stratolaunch

Stratolaunch represents an unprecedented use of composites in an aircraft. Optimizing the design of composites for the launcher was a daunting challenge.

Read More