CW Blog

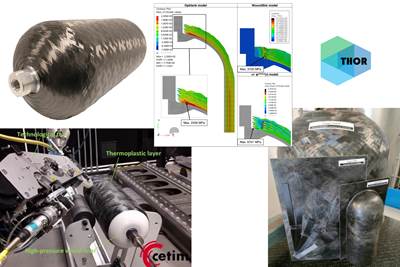

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreDefense manufacturer reflects on growth, opportunity in complex composite structures

Long Island-based, four-time CW Top Shops honoree GSE Dynamics cites diversification in processes, digitalization, workforce training and more on its successes over 50+ years, and looks ahead to future growth.

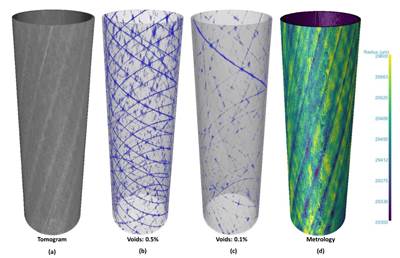

Read MoreMulti-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

Read MoreIndustrial equipment manufacturer expands global footprint, reaches into new markets

India-based CW Top Shops honoree EPP Composites reflects on a recently successful vertical filament winding application and new pultruded FRP rebar capabilities, as well as future opportunities.

WatchRepurposing wind blades as functional community art pieces

Ohio-based Canvus Inc. upcycles fiberglass wind blades, car tires and post-consumer plastics to create outdoor furniture that amplifies sustainability messages in community spaces.

WatchFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

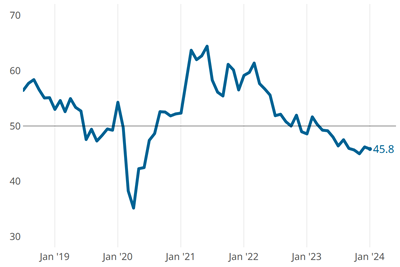

Read MoreComposites industry activity stayed steady in January

The GBI: Composites Fabricating contracted in January to about the same degree it did in December, representing a move in the right direction.

Read MoreComposites end markets: Industrial (2024)

The use of composites in industrial applications is increasing, driven by the need for higher performance and longer life, whether its parts for industrial machinery, EOAT components, corrosion-resistant equipment and more.

Read MoreBallistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

Read MoreFinnish boatbuilder balances history, innovation in fiberglass composites design

CW Top Shops honoree Sargo Oy shares its successes in upgrading operations from hand layup to infusion, employing low-waste manufacturing practices, research in large-format 3D printing for mold production and more.

Read MoreWhat’s new for 2024?

CompositesWorld discusses recent changes, upcoming events and strategies for the upcoming year.

Read MoreBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

Watch