CW Blog

Composites evolution, big and small

We like to focus on the Next Big Thing in composites, but everyday processes need attention too.

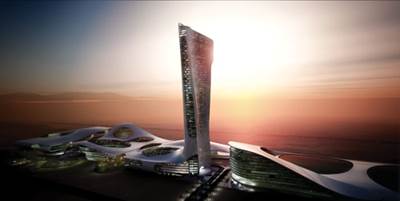

Read MoreThe building envelope: Betting on the big time

Building code changes and growing architect familiarity feed more frequent composites use in large-scale commercial construction.

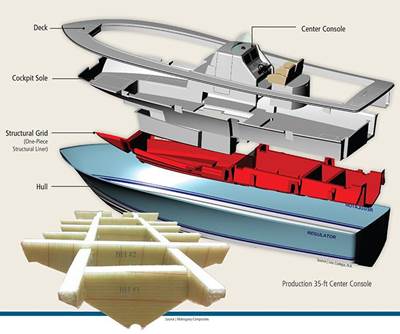

Read MoreThe structural grid: Prefabrication

Digitally designed and cut, preformed and preinfused stringers and bulkheads reduce boat weight, labor and cycle time and improve boatbuilder process control.

Read MoreComposites slake the world's thirst

As the global thirst for drinkable water increases, the composites industry is drinking in the tremendous possibilities in seawater desalination.

Read MorePaddleboard productivity: Adhesively bonded hull/deck is key

Dragonfly Boatworks LLC's (Vero Beach, Fla.) new standup paddleboard for fly fishing is built without fasteners, with the aid of SG200-40 methacrylate adhesive from SCIGRIP Smarter Adhesive Solutions (Durham, N.C.).

Read MoreDeep draw: Unique laminate architecture enables bus part

For a major mass-transit manufacturer, Amtech LLC (Wapato, Wash.) successfully thermoforms a luggage cover with a remarkably deep draw of 40 inches (1,016 mm), using a laminate architecture that includes a top layer of 0.180-inch/4.5-mm gauge Grade 4800 thermoplastic sheet, supplied by Boltaron (Newcomerstown, Ohio).

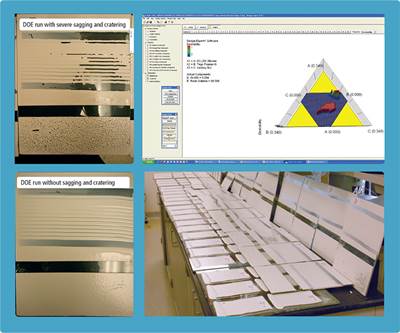

Read MoreCure for cratering: Gel coat perfected with design of experiments software

Resin manufacturer Interplastic Corp. – Thermoset Resins Div. (St. Paul, Minn.), a major gel coat producer, recently developed a new gel coat with the aid of Design-Expert design of experiments software from Stat-Ease Inc. (Minneapolis, Minn.).

Read MoreU.S. playing catch-up in offshore wind race

With excellent wind resources off the U.S. East Coast, it's high time wind energy developers start investing in the region. A promising start might be underway off the coast of Maine, where Statoil is working to develop a floating turbine.

Read MoreIn new Corvette Stingray, another step forward for composites

Plasan Carbon Composites puts its "pressure press" process, developed with Globe Machine, to work in the manufacture of the hood and roof for the new 2014 Corvette Stingray, introduced last week at the Detroit Auto Show.

Read MoreTenCate's acquisition of Amber Composites a sensible surprise

TenCate, known for years as a thermoplastics specialist, is signaling more and more that it wants to move into new markets with new materials.

Read MoreNext-generation braiding for next-gen bike

When Grenchen, Switzerland-based Bicycle Manufacturing Co. (BMC) decided to braid the tubes for its impec racing bike frame, the use of carbon fiber and the complex tube designs and shapes prompted the use of radial braiding technology from August Herzog Maschinenfabrik GmbH & Co. KG (Oldenburg, Germany)

Read More